Table 1.

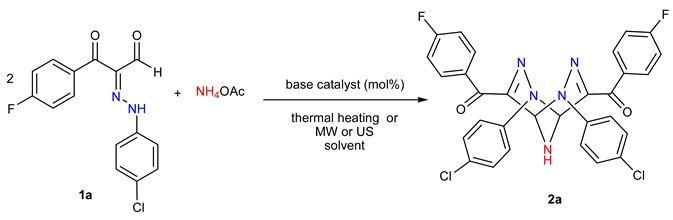

Optimization the dimerization condition of 3-oxo-2-arylhydrazonopropanals 1a with ammonium acetate a.

| Run | Base-Catalyst (mol%) | Solvent | Conv. Heating | Sonication | MW Irradiation | |||

|---|---|---|---|---|---|---|---|---|

| Yield b % | Time (h) | Yield b % | Time (min) | Yield b % | Time (min) | |||

| 1 | No catalyst | EtOH | trace | 15 | trace | 120 | trace | 30 |

| 2 | Et3N (15) | EtOH | 70 | 4 | 82 | 60 | 87 | 5 |

| 3 | Et3N (25) | EtOH | 78 c | 3 | 89 d | 50 | 94 | 3 |

| 4 | Et3N (30) | EtOH | 71 | 3 | 85 | 60 | 90 | 4 |

| 5 | Et3N (25) e | EtOH | 66 e | 3 | 73 e | 50 | 80e | 3 |

| 6 | Et3N (25) f | EtOH | 60 f | 3 | 68 f | 50 | 73f | 3 |

| 7 | Et3N (25) | MeOH | 71 | 4 | 82 | 50 | 89 | 4 |

| 8 | Et3N (25) | isopropanol | 70 | 4 | 80 | 60 | 88 | 4 |

| 9 | Et3N (25) | n-hexane | 34 | 6 | 52 | 80 | 63 | 10 |

| 10 | Et3N (25) | acetic acid | 32 | 4 | 40 | 70 | 50 | 6 |

| 11 | Et3N (25) | DMF | 30 | 6 | 45 | 100 | 55 | 10 |

| 12 | Et3N (25) | toluene | 35 | 5 | 50 | 90 | 65 | 10 |

| 13 | pyridine (25) | EtOH | 20 | 4 | 28 | 60 | 35 | 5 |

| 14 | DABCO (25) | EtOH | 17 | 5 | 20 | 80 | 28 | 7 |

| 15 | DBU (25) | EtOH | 15 | 5 | 18 | 70 | 25 | 8 |

| 16 | NaHCO3 (25) | EtOH | 10 | 6 | 10 | 80 | 15 | 10 |

| 17 | K2CO3 (25) | EtOH | 10 | 5 | 12 | 90 | 15 | 10 |

| 18 | NaOH (25) | EtOH | 12 | 5 | 14 | 80 | 18 | 9 |

a Reaction conditions: Arylhydrazonopropanal 1a (5 mmol), ammonium acetate (10 mmol) and base-catalyst (15~30 mol%) in solvent (7 mL) at reflux temperature for conventional heating 3~6 h, ultrasonic irradiation at 80 °C (110 W) for 50~100 min, or microwave irradiation at 80 °C (200 W) for 3~10 min. b isolated yield. c Yield was 20% after 50 min. d Yield was 35% after 15 min. e Compound 1a (5 mmol) and ammonium acetate (5 mmol) were used. f Compound 1a (10 mmol) and ammonium acetate (5 mmol) were used. Conv. = conventional, MW = microwave.