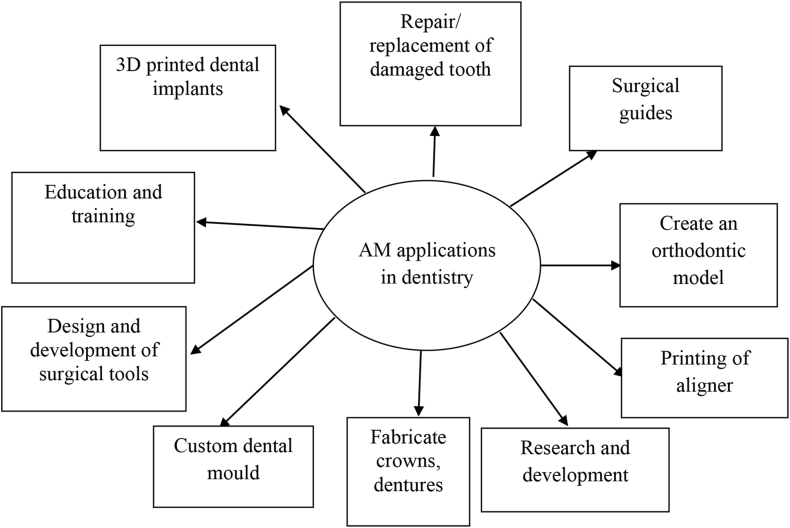

Fig. 2.

-

•3D printed dental implants: During dental implant surgery, AM plays an essential role to provide the best solution for creating a template of 3D model which is helpful for the replacement of missing tooth. It improves the accuracy of the surgery as compared to the traditional method. This technique is economical and comfortable in which the dental model gets an excellent surface finish.45, 46, 47, 48

- •

- •

- •

- •

- •

-

•Fabricate crowns, dentures: This technology is used to fabricate crown rapidly. Patient teeth are scan and crown is directly printed that save time, and further can also be modified. It prints complete denture with gum and teeth. Multi-material is used to print and all kinds of dental implants and models. It uses explicit material for the printing process.63, 64, 65

- •

- •

-

•Education and training: It is important to train medical students for performing various clinical trial and practices. Product manufactured by this technology provide a better demonstration, as model fabricated by this technology is colourful, so it is useful in dentistry for teaching.71, 72, 73, 74