Table 1.

Optimization of Reaction Conditionsa

| |||||

|---|---|---|---|---|---|

| entry | [Pd] source (mol %) | solvent | solvent temp (°C) | time (h) | yield (%)b |

| 1 | Pd2(dba)3/PPh3 (2.5/6) | CH2Cl2 | −50 to 0 | 5 | 52 |

| 2 | Pd2(dba)3/PPhCy2 (2.5/6) | CH2Cl2 | −50 to 0 | 5 | 22 |

| 3 | Pd2(dba)3/P(o- MeOC6H4)3 (2.5/6) |

CH2Cl2 | −50 to 0 | 5 | 5 |

| 4 | Pd2(dba)3/P(p- MeOC6H4)3 (2.5/6) |

CH2Cl2 | −50 to 0 | 5 | 44 |

| 5 | Pd2(dba)3/dppf (2.5/6) | CH2Cl2 | −50 to 0 | 5 | 36 |

| 6 | [Pd(allyl)Cl]2/PPh3 (2.5/6) | CH2Cl2 | −50 to 0 | 5 | 51 |

| 7 | Pd(PPh3)4 (5) | CH2Cl2 | −50 to 0 | 5 | 57 |

| 8 | Pd(PPh3)4 (5) | CH2Cl2 | −20 | 20 | 70 |

| 9 | Pd(PPh3)4 (5) | EtCN | −20 | 20 | 70 |

| 10 | Pd(PPh3)4 (5) | EtOAc | −20 | 20 | 72 (62) |

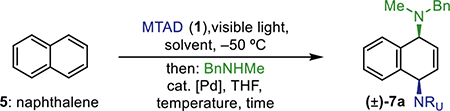

Standard reaction conditions: MTAD (1, 0.5 mmol, 1.0 equiv), naphthalene (5, 1.0 mmol, 2.0 equiv), solvent (0.1 M), visible light, −50 °C, 12 h; then addition of BnNHMe (1.0 mmol, 2.0 equiv) and [Pd] catalyst in THF.

Determined by 1H NMR integration relative to the internal standard. Isolated yield shown in parenthesis.