Abstract

BACKGROUND:

Utilization of attachments in a removable partial denture is highly essential not only as a line of treatment but also as it has a remarkable impact on the denture’s durability during the function. The attachment should act as a stress breaking system preserving the abutment teeth.

AIM:

This consideration aimed to verify the convention of polyether ether ketone (PEEK) material as an attachment.

MATERIAL AND METHODS:

Four groups of different materials for both attachments and partial denture framework were fabricated and tested using strain gauges to compare between them according to the strains originated around both the abutment teeth and edentulous area.

RESULTS:

PEEK material is one of the esthetic materials used for fabrication of the framework of the RPD. On using it as a precision attachement is shows favorable stress distribution decreasing the strains around the abutment teeth and the alveolar ridge especially distal to the abutment teeth that was significantly reduced in comparison with the other treatment options.

CONCLUSION:

Utilization of PEEK material as both an attachment and framework decline the strains performed around the abutment teeth and over the edentulous ridge.

Keywords: Removable Partial Denture (RPD), PEEK Material, Attachment system, Strain gauges

Introduction

One of the challenging cases in Oral prosthodontics is treating a distal extension case removable partial denture (Kennedy’s Class I and Class II). The best treatment plan for restoring such case is implant supported prosthesis, although it is not feasible in some cases either due to insufficient bone or economic reasons [1]. Hence, a castable removable partial denture is mostly preferred.

One of the affordable non-invasive solutions for rehabilitation of Kennedy’s Class I and Class II cases is the removable partial denture which requires careful attention and meticulous treatment planning for restoring both esthetics and functional patient’s desires [2], [3], [4]. Moreover, the simplicity of the framework design is extensively essential together with logical principles to diminish the associated complains that most commonly take place with removable partial denture rehabilitation [5], [6].

Attachments solved the esthetic problems associated with employing clasps especially in the anterior region [7]. A semi-precision attachment utilised with cast metal framework removable partial denture can enhance tremendous roles as both retention and esthetics that increase patient’s self-confidence [5], [6], [8].

Since enhancing the clinical success with semi-precision attachment, it is recommended to involve at least two abutment teeth in distal extension cases aiming to eliminate the hazards impacts of excessive abutment loading by utilising an adjustable retentive plastic insert [9], [10], [11].

Rehabilitating Kennedy’s Class II cases with a unilateral partial denture rises the patient’s comfort and diminishing the adaptation period as the major connector’s absence has major merit compared to the conventional removable partial denture [12].

The newly introduced PEEK [Polyether ether ketone] material in the dental market can be a nonmetallic alternative material for removable partial denture framework construction [13], [14]. Despite that limited contemplates employed PEEK as a denture base material, but some proved that such matter is of superior mechanical criteria including superior flexure behaviour with highest ability to spring back to its original shape after the load is released. These studies revealed the applicability of PEEK material in dentistry allowing offering the patient a metal-free restoration with superior mechanical properties [15], [16], [17], [18].

In-vitro studies provide the merit of repeating the considerations under the same circumstances together with the similar supporting teeth and mucosa which is not available in the in-vivo ones [19]. Thus, comparative would be more accurate and practical if they were laboratory performed.

One of the devices used to calibre the in-vitro contemplates is the Strain gauge which measures the objects’ strain. This gauge comprises a flexible insulating backing that supports a metallic foil pattern which is attached with suitable adhesive. When applying a load to the object, the object is deformed which makes the foil to be deformed causing its electrical resistance to change [20], [21].

Hence, this in-vitro contemplate aimed is to evaluate the strain induced by different prosthetic options utilising PEEK material in lower Kennedy’s Class II case.

Material and Methods

A mandibular model fabricated for educational purposes and constructed from acrylic resin* (Nissin dental products Inc. Kyoto Japan) was utilised as a master model replicating the anatomical features of both the teeth and soft tissues. Molars on one side of the model were removed, and their sockets were sealed with base plate wax* (Cavex set up regular, Modeling Wax, Cavex Holland.) to represent Kennedy class II partially edentulous cases.

This master model was duplicated to epoxy resin one by flashing technique using epoxy resin* (Kemapoxy 150 JM, CBM International). Then, four different treatment prosthetic options were fabricated forming four different groups.

Group 1: On the edentulous side, the first and second premolars were reduced and prepared for full coverage metal crowns with lingual ledge attached to its cast OT CAP unilateral attachment*(OT Unilateral, Rhein 83srl, Bologna, Italy). Then unilateral metal cast partial denture* (Cobalt-Chromium metal framework, vita, Switzerland) was constructed as for Kennedy class II cases according to the manufacturer’s instructions.

Figure 1.

Full coverage metal crowns with lingual ledge attached to it cast OT CAP unilateral attachment, and unilateral metal cast partial denture

Group 2: On the reduced premolars, a full coverage metal crowns with lingual ledge attached to it OT CAP unilateral attachment were cast. Then thermoplastic PEEK* (BioHpp PEEK, Bredent, Germany) material used for fabrication of the unilateral partial denture. For the esthetic purpose the Visio.lign* (Visio. align, Bredent, Germany.) was used for the buccal flange of the partial denture used for Kennedy class II cases by the lost wax technique according to the manufacturer’s guidelines.

Group 3: On the reduced premolars, full coverage PEEK crowns with lingual ledge attached to it OT CAP unilateral attachment were constructed. Then thermoplastic PEEK material unilateral partial denture with Visio.lign for buccal flange was constructed as for Kennedy class II cases.

Figure 2.

full coverage PEEK crowns with lingual ledge attached to it cast OT CAP unilateral attachment and Then thermoplastic PEEK material unilateral partial denture with Visio.lign for buccal flange

Group 4: On the reduced premolars, full coverage PEEK (polyether ether ketone) crowns with lingual ledge attached to it OT CAP unilateral attachment were constructed. Then unilateral metal cast partial denture was constructed as for Kennedy class II cases.

A pencil was utilised to delineate the crest of the residual ridge on the cast. Micro OT CAP parallometer mandrel* (Parallometer key for O T cap.) was employed to take the attachment from the kit and insert it into the mandrel tip carefully without squeezing the attachment between the mandrel head. Then, the mandrel was connected to parallometer to position the attachment little to the lingual aspect of the ridge to improve esthetics in final restoration and to beast functionality.

The ledge was prepared on the lingual surface of the premolars wax pattern to receive a lingual bracing arm. The attachment was positioned carefully and fixed with wax or adhesive component. The positional ring was applied over the attachment. Then, the crowns-attachment assembly was checked on the model, and the completed wax pattern was spread, invested and cast into either metal or PEEK crowns.

UNI Box was fit exactly on the attachment and flushed smoothly with abutment wax coping. Then a layer of wax was adapted on the residual cast ridge before applying the saddle and then joining the castable connector to UNI Box by resin to reinforce the structure. The completed wax pattern was spread, invested and cast into either metal or PEEK partial framework.

Electrical strain gauges using a fully digitalised universal testing machine (LLOYD) were then utilised to record the microstrains generated upon using the four different designs investigated in this consideration. Five strain gauges were employed to calibre the microstrains produced at the buccal, lingual, mesial and distal surfaces of the splinted abutments with each design next to reducing the acrylic resin surrounding the first and second premolars on the edentulous side and one at the mid of the edentulous area beneath the partial framework.

A spring type loading device capable of applying a wide range (Ascending load is applied at the acrylic bite block from 0 to 200 N with the loading tip of the device on the loading point of the acrylic block) of static loads was used to load the prosthesis. Then, all the collected data were tabulated collected and statistically analysed.

Statistical analysis

Data were presented as mean, standard deviation (SD) and Standard Error (SE). Data explored for normality using Kolmogorov-Smirnov and Shapiro-Wilk tests. The strain showed a parametric distribution, so One Way ANOVA used to compare between tested groups followed by a post hoc test for pairwise comparison.

The significance level was set at P ≤ 0.05.

Statistical analysis was performed with IBM® SPSS® (SPSS Inc., IBM Corporation, NY, USA) Statistics Version 24 for Windows.

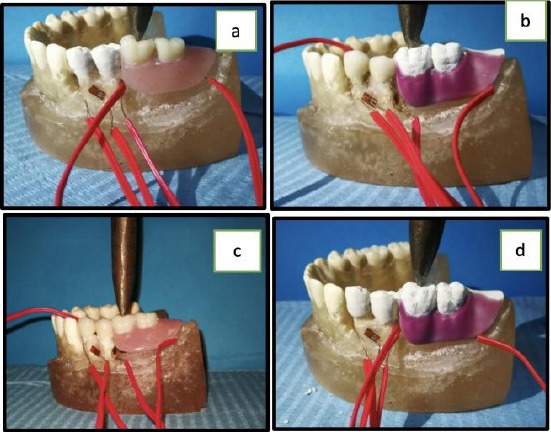

Figure 3.

a- Group 4, b- Group 2, c- Group1, d- Group 3

Results

Mean, and standard deviation (SD) for the difference in Strain for different tested groups were presented in Table 1.

Table 1.

Mean and standard deviation (SD) for Strain for different tested groups

| Material | p-value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M-M | M-P | P-P | P-M | |||||||

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |||

| Strain | Mesial | 182.50b | 6.45 | 100.00a | 4.08 | 23.75d | 4.79 | 25.00c | 4.08 | ≤0.001* |

| Buccal | 305.00a | 4.08 | 352.50b | 6.45 | 102.50c | 6.45 | 162.50b | 6.45 | ≤0.001* | |

| Distal | 230.00a | 4.08 | 1013.75d | 11.09 | 407.50c | 6.45 | 417.50b | 6.45 | ≤0.001* | |

| Lingual | 138.75a | 4.79 | 120.00a | 4.08 | 75.00b | 4.08 | 115.00a | 4.08 | ≤0.001* | |

| Ridge | 632.50a | 6.45 | 227.50b | 6.45 | 462.50c | 6.45 | 568.75b | 8.54 | ≤0.001* | |

| Total | 297.75 | 180.86 | 362.75 | 346.51 | 214.25 | 187.65 | 257.75 | 208.25 | 0.140 NS | |

= Significant, NS = Non-significant.

Correlation between Distal and Ridge Strain is shown in Table 2.

Table 2.

Pearson correlation coefficient for different tested areas

| Mesial | Buccal | Distal | Lingual | ||

|---|---|---|---|---|---|

| Ridge | Pearson Correlation | 0.168 | -0.369 | -0.963** | 0.205 |

| Sig. (2-tailed) | 0.533 NS | 0.159 NS | ≤0.001* | 0.447 NS | |

| N | 16 | 16 | 16 | 16 | |

= Significant, NS = Non-significant.

Discussion

The unilateral designed partial denture has a significantly greater movement than a bilateral designed partial denture. So, a meticulous design should be achieved by employing a stress equalising design to decline the stress on the abutments [22].

From previous in-vitro investigations [12], [22] they recommend involving at least two vital and periodontally healthy abutments upon using extra-coronal attachment system. As the extra-coronal attachment introduce more stress at terminal abutment tooth when compared with clasp retained the denture.

The extra-coronal precision attachment is indicated for long span distal extension bases as it provides a removable prosthesis with improved esthetics and improved comfort with less post-operative adjustments [23].

RHEIN 83 OT CAP is an extra-coronal attachment used at the distal end of the splinted abutments and cast with the crowns. The male component design is a sphere with a flat head, and female component is retentive nylon caps which are colour-coded according to different retentive properties [24].

In one of the researches that compare different designs of unilateral partial dentures with extra-coronal attachments and different lengths of distal extension bases, it was concluded that the amount of stresses affects the abutments in the short saddle design are far lower than the long saddle one. So, it is recommended to use extra-coronal attachments in short Kennedy Class II cases unilaterally designed restoring two missing teeth [25].

To achieve the gingival colour of the PEEK framework of the partial denture, Visio-like can be used, and other materials as acid etching composite material can be applied [26]. The PEEK framework should not be cast to full contour to counteracts the esthetic point of view of PEEK framework from low translucency and greyish pigmentation.

Four different treatment options were designed in this in-vitro study to compare the stress distribution around the splinted abutment teeth and over the edentulous ridge. By using the strain gauge evaluation method, the PEEK-PEEK treatment option expresses the most favourable stress distribution in all aspects especially around the abutment teeth and this outcome coincides with the researches about the favourable of the PEEK material [13], [15], [17], [18], [27], [28] both biologically and mechanically especially for its flexure behaviour which is the main cause of its favourable distribution of stresses.

From the outcomes of this in-vitro study, it can be accomplished that PEEK material proved to be one of the non-metallic materials of choice due to its superior properties regarding both biologically and mechanically for restoring short unilateral partial free end edentulous cases with extra-coronal precision attachment.

Footnotes

Funding: This research did not receive any financial support

Competing Interests: The authors have declared that no competing interests exist

References

- 1.Carr AB, Brown DT. McCracken's Removable Partial Prosthodontics-E-Book. Elsevier Health Sciences. 2010:12. [Google Scholar]

- 2.Gunne HJ. The effect of removable partial dentures on masticatory function and dietary intake. Acta Odontol Stand. 1985;43:269–278. doi: 10.3109/00016358509046507. https://doi.org/10.3109/00016358509046507. [DOI] [PubMed] [Google Scholar]

- 3.D. J Witter, et al. The effect of removable partial dentures on the oral function in shortened dental arches. J Oral Rehabil. 1989;16:27–33. doi: 10.1111/j.1365-2842.1989.tb01314.x. https://doi.org/10.1111/j.1365-2842.1989.tb01314.x PMid:2746404. [DOI] [PubMed] [Google Scholar]

- 4.Partielle adjoint. Rev Mens Suisse. Restoration of the partially edentulous mouth-a comparison of overdentures, removable partial dentures, fixed partial dentures and implant treatment. Odontostomatol. 1995;105:507–511. doi: 10.1016/0300-5712(95)00075-5. [DOI] [PubMed] [Google Scholar]

- 5.Zajc D, Wichmann M, Reich S, Eitner S. A prefabricated precision attachment:3 years of experience with the Swiss Mini-SG system. A prospective clinical study. Int J Prosthodont. 2007;20:432–434. PMid:17695879. [PubMed] [Google Scholar]

- 6.Johannes Schmitt, Manfred Wichmann, PhD, Stephan Eitner, PhD, Jorg Hamel. Five-year clinical follow-up of prefabricated precision attachments:A comparison of uni and bilateral removable dental prostheses Quintessence Int. 2011;42:413–418. PMid:21519561. [PubMed] [Google Scholar]

- 7.Shillingburg HT, Jr, S Hobo, LD Whitsett, R Jacobi, Se Brackett. Fundamentals of fixed prosthodontics. Chicago: Quintessence; 1997. pp. 531–2. [Google Scholar]

- 8.Den Haan R, et al. (Semi-)precision attachments for cast metal frame removable partial dentures. Nederland's tijdschrift voor tandheelkunde. 2011;118(2):93–100. doi: 10.5177/ntvt.2011.02.10290. https://doi.org/10.5177/ntvt.2011.02.10290. [DOI] [PubMed] [Google Scholar]

- 9.Altay OT, Tsolka P, Preiskel HW. Abutment teeth with extracoronal attachments:The effects of splinting on tooth movement. Int J Prosthdont. 1990;3:441–448. PMid:2088381. [PubMed] [Google Scholar]

- 10.Yeung AL, Lo EC, Chow TW, Clark RK. Oral health status of patients 5-6 years after placement of cobalt-chromium removable partial dentures. J Oral Rehabil. 2000;27:183–189. doi: 10.1046/j.1365-2842.2000.00512.x. https://doi.org/10.1046/j.1365-2842.2000.00512.x PMid:10784329. [DOI] [PubMed] [Google Scholar]

- 11.El-Charkawi H.G, Zekry K.A, El-Wakad M.T. Stress analysis of two osseointegrated implants supporting distal extension prosthesis. AL-Azhar Dent J. 1996;7:347–362. doi: 10.1016/0022-3913(94)90294-1. [DOI] [PubMed] [Google Scholar]

- 12.Patrnogić V, Todorović A, Sćepanović M, Radović K, Vesnić J, Grbović A. Free-end saddle length influence on stress level in unilateral complex partial denture abutment teeth and retention elements. Vojnosanit Pregl. 2013;70(11):1015–22. doi: 10.2298/vsp110603028p. https://doi.org/10.2298/VSP110603028P. [DOI] [PubMed] [Google Scholar]

- 13.Stawarczyk B, Beuer F, Wimmer T, Jahn D, Sener B, Roos M, Schmidlin PR. Polyetheretherketone-a suitable material for fixed dental prostheses? J Biomed Mater Res B Appl Biomater. 2013;101:1209–16. doi: 10.1002/jbm.b.32932. https://doi.org/10.1002/jbm.b.32932 PMid:23564476. [DOI] [PubMed] [Google Scholar]

- 14.Costa-Palau, et al. Use of Polyetheretherketone in the fabrication of a maxillary obturator prosthesis:A clinical report. J Prosthet Dent. 2014;112(3):680–2. doi: 10.1016/j.prosdent.2013.10.026. https://doi.org/10.1016/j.prosdent.2013.10.026 PMid:24630397. [DOI] [PubMed] [Google Scholar]

- 15.Muhsin SA, Wood DJ, Hatton PV, Johnson A, Sereno N. The Effect of Processing Conditions on the Flexural Strength of Polyetheretherketone (PEEK) Used as Innovative Denture Base Material. The 2nd International PEEK Meeting, USA-Washington DC, 23-24th April. 2015 [Google Scholar]

- 16.Godara A, Raabe D, Green S. The influence of sterilisation processes on the micromechanical properties of carbon fiber-reinforced PEEK composite for bone implant applications. Acta Biomater. 2007;3(2):209–20. doi: 10.1016/j.actbio.2006.11.005. https://doi.org/10.1016/j.actbio.2006.11.005 PMid:17236831. [DOI] [PubMed] [Google Scholar]

- 17.Sagomonyants KB, et al. The in vitro response of human osteoblasts to Polyetheretherketone (PEEK) substrates compared to commercially pure titanium Biomaterials. 2008; 29:1563–72. doi: 10.1016/j.biomaterials.2007.12.001. https://doi.org/10.1016/j.biomaterials.2007.12.001 PMid:18199478. [DOI] [PubMed] [Google Scholar]

- 18.Schwitalla AD, et al. Flexural behavior of PEEK materials for dental application. Dent Mater. 2015;31(11):1377–84. doi: 10.1016/j.dental.2015.08.151. https://doi.org/10.1016/j.dental.2015.08.151 PMid:26361808. [DOI] [PubMed] [Google Scholar]

- 19.Asundi A, Kishen A. A strain gauge and photoelastic analysis of in vivo strain and in vitro stress distribution in human dental supporting structures. Archives of oral biology. 2000;45(7):543–50. doi: 10.1016/s0003-9969(00)00031-5. https://doi.org/10.1016/S0003-9969(00)00031-5. [DOI] [PubMed] [Google Scholar]

- 20.Dahab IA, El-Gendy AA, Eltorky IR. In vitro stress analysis study of different prosthetic options using single posterior implant for management of mandibular unilateral distal extension saddle. Tanta Dental Journal. 2015;12(1):7–15. https://doi.org/10.1016/j.tdj.2014.07.004. [Google Scholar]

- 21.Karl M, Dickinson A, Holst S, Holst A. Biomechanical methods applied in dentistry:a comparative overview of Photo elastic examinations, strain gauge measurements, finite element analysis and three-dimensional deformation analysis. Eur J Prosthodont Restor Dent. 2009;17(2):50–7. PMid:19645304. [PubMed] [Google Scholar]

- 22.Schmitt J, Wichmann M, Eitner S, Hamel J, Holst S. Five-year clinical follow-up of prefabricated precision attachments:A comparison of uni-and bilateral removable dental prostheses. Quintessence International. 2011;42(5):413–18. PMid:21519561. [PubMed] [Google Scholar]

- 23.Feinberg E. Diagnosing and prescribing therapeutic attachment-retained partial dentures. The New York state dental journal. 1982;48(1):27–29. PMid:7031533. [PubMed] [Google Scholar]

- 24.Gupta N, Bhasin A, Gupta P, Malhotra P. Combined Prosthesis with Extracoronal Castable Precision Attachments. Case reports in dentistry. 2013;2013 doi: 10.1155/2013/282617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Patrnogi V, et al. Free-end saddle length influence on stress level in unilateral complex partial denture abutment teeth and retention elements Vojnosanit Pregl. 2013;70(11):1015–22. doi: 10.2298/vsp110603028p. https://doi.org/10.2298/VSP110603028P. [DOI] [PubMed] [Google Scholar]

- 26.Stawarczyk B, Beuer F, Wimmer T, Jahn D, Sener B, Roos M, Schmidlin PR. Polyetheretherketone-A suitable material for fixed dental prostheses? J Biomed Mater Res Part B. 2013;101B:1209–16. doi: 10.1002/jbm.b.32932. https://doi.org/10.1002/jbm.b.32932 PMid:23564476. [DOI] [PubMed] [Google Scholar]

- 27.Tekin S, Cangül S, Adıgüzel Ö, Değer Y. Areas for use of PEEK material in dentistry. International Dental Research. 2018;8(2):84–92. https://doi.org/10.5577/intdentres.2018.vol8.no2.6. [Google Scholar]

- 28.Skirbutis G, Dzingutė A, Masiliūnaitė V, Šulcaitė G, Žilinskas J. A review of PEEK polymer's properties and its use in prosthodontics. Stomatologija. 2017;19(1):19–23. PMid:29243680. [PubMed] [Google Scholar]