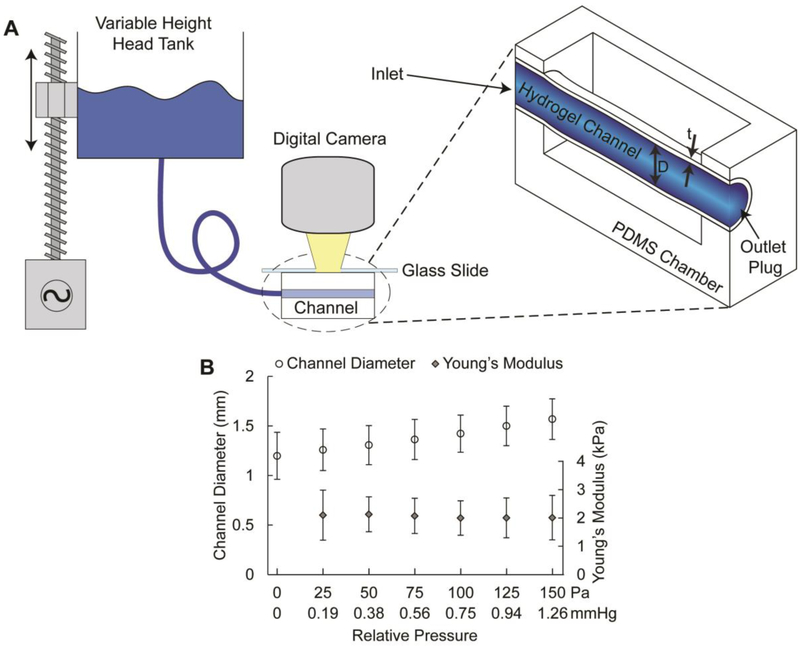

Figure 2.

Mechanical properties of hydrogel channels. (A): Schematic for pressure-dilation experiments on hydrogel channels. The head tank was driven by a linear actuator in 2.54 mm increments. An FEP tubing connected the head tank to one end of the PDMS chamber while the outlet was plugged. The chamber well was filled with HA-Tz and topped with a glass slide to prevent distortion effects from the fluid meniscus. A calibrated Dino-Lite camera was positioned over top of the channel to capture images of channel dilation during step changes in head pressure (D: channel diameter; t: wall thickness). (B): Average channel diameter and Young’s modulus as a function of relative pressure over the range of 0-150 Pa. Young’s modulus was calculated via best fit (R2 > 0.99) of a stress-strain model for cylindrical pressure vessels with variable modulus and thickness to experimental data. The error bars represent standard deviation (n = 6).