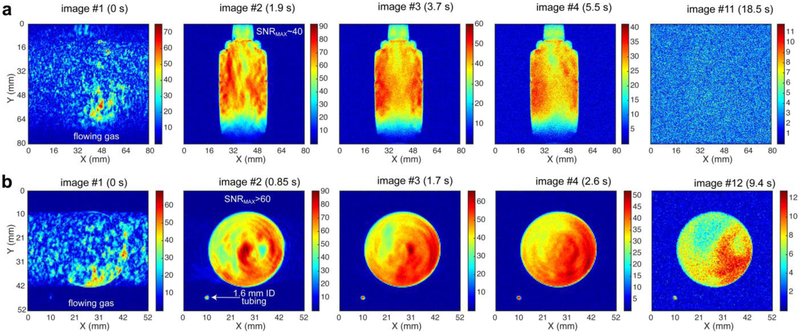

Figure 4.

(a) 2D MRI of ~0.2 standard liters of HP propane gas in ~56 mL collection container after production of ~0.3-standard-liter (sL) batch of HP propane in ~2 seconds using an 1:2 mixture of propylene with p-H2. These 2D slices were acquired on a 4.7 T MRI instrument with the following imaging parameters: 2D gradient echo (GRE) images were acquired every ~1.85 sec/slice, 256×256 matrix with repetition time (TR) ~ 7.2 ms, slice thickness = 8 mm; field of view = 80×80 mm2, pixel size (spatial resolution) ~ 0.3×0.3 mm2, voxel size ~ 78 micro-liter; (b) similar 2D acquisition (axial projection): ~0.85 sec/slice, 128×128 matrix with TR ~ 6.6 ms, slice thickness = 12 mm. Field of view = 52×52 mm2, pixel size (spatial resolution) ~ 0.4×0.4 mm2, voxel size ~ 200 micro-liter. HP propane was produced using the following reaction conditions: batch-mode, propylene/p-H2 ratio = 1 : 2, catalyst mass = 280 mg, t = 100 °C.