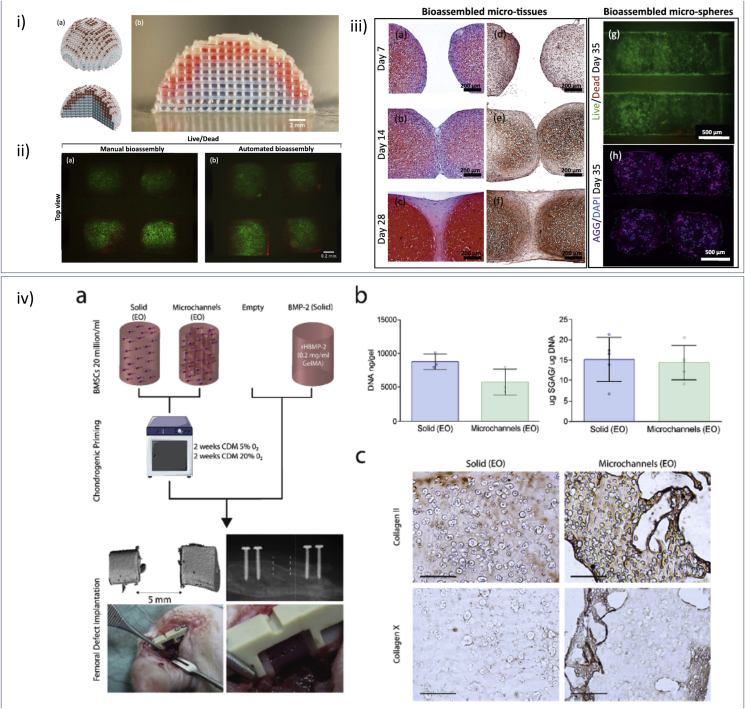

Fig. 7.

Scaling up cell printing approaches. (i–a) Illustration of a computer aided design (CAD) example of an assembled hemispherical construct for osteochondral joint resurfacing. (i–b) A biphasic hemispherical construct with stained GelMA hydrogel micro-spheres representing chondrogenic (red) and osteogenic (blue) phase of an osteochondral construct fabricated by applying the bottom-up automated tissue bioassembly strategy. Scale bars: 2 mm. Fluorescence microscopy images of (ii - a) a manually assembled construct and (ii - b) a construct assembled using the bioassembly system stained with Calcein AM (live cells, green) and Propidium Iodide (dead cells, red). (iii - a-f) Histological analysis of assembled micro-tissues and associated tissue fusion in adjacent culture over 28 days. Histological sections stained with (iii - a-c) Safranin-O/Haematoxylin/fast green or (iii - e, f) Collagen II antibodies. Bioassembled HAC-laden 9.5%GelMA-0.5%HepMA micro-spheres (iii - g, h) stained with Calcein AM (live cells, green) and Propidium Iodide (dead cells, red) (iii - g) or DAPI(blue) and Aggrecan (purple) antibodies (iii - h) after 35 days culture in chondrogenic differentiation media. Adapted with permission [100] CC BY license. (iv - a) Outline of experimental groups (solid and micro channelled) and control groups (empty and BMP-2); pre-implantation chondrogenic culture conditions; and implantation of primed hydrogel (channelled) into a 5 mm femoral defect. (iv - b) Biochemical analysis (Total DNA/construct (n = 3) and sGAG/DNA (n = 5) of both groups after 4 weeks of in vitro culture. (iv - c) Immunohistochemical staining for collagen II pre-implantation, 4 × scale-bar 1 mm. Adapted with permission [77] CC BY license.