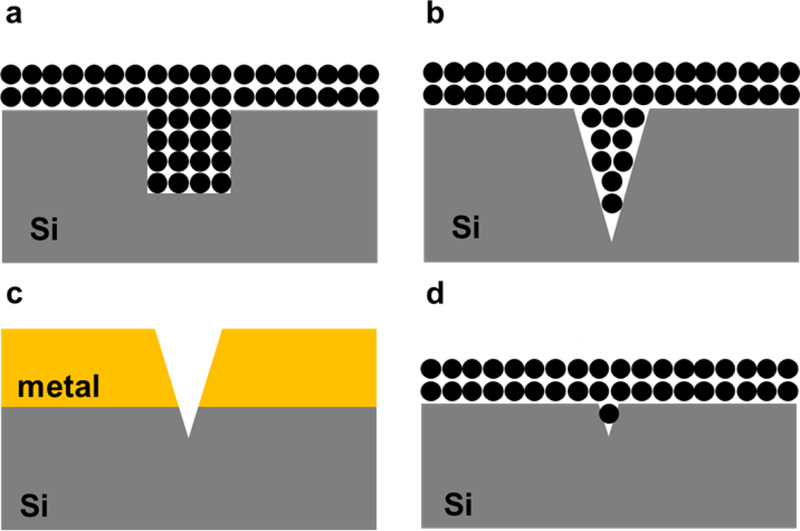

Fig. 1.

Schematic of the UV-resin filling issue for nanostructures fabricated by direct FIB milling (a, b) and small nanostructures fabricated by metal-assist FIB milling (c, d). Black spheres represent UV-resin monomers and the dimensions are chosen arbitrarily for illustration purpose. Fig. 1(a) and Fig. 1(b) have the same nanochannel width and different nanochannel depth. When milled deeper, the nanochannel cross-sectional profile becomes V-shaped. Such profile prevents complete UV-resin filling, especially for monomers with large molecular size. Metal-assist FIB milling is used to fabricate small nanostructures by coating a hundreds nanometer thick metal sacrificial layer on top of Si substrate. After removing the metal layer, the structure left on Si has small and V-shaped cross-sectional profile. UV-resin filling into such structure is much harder.