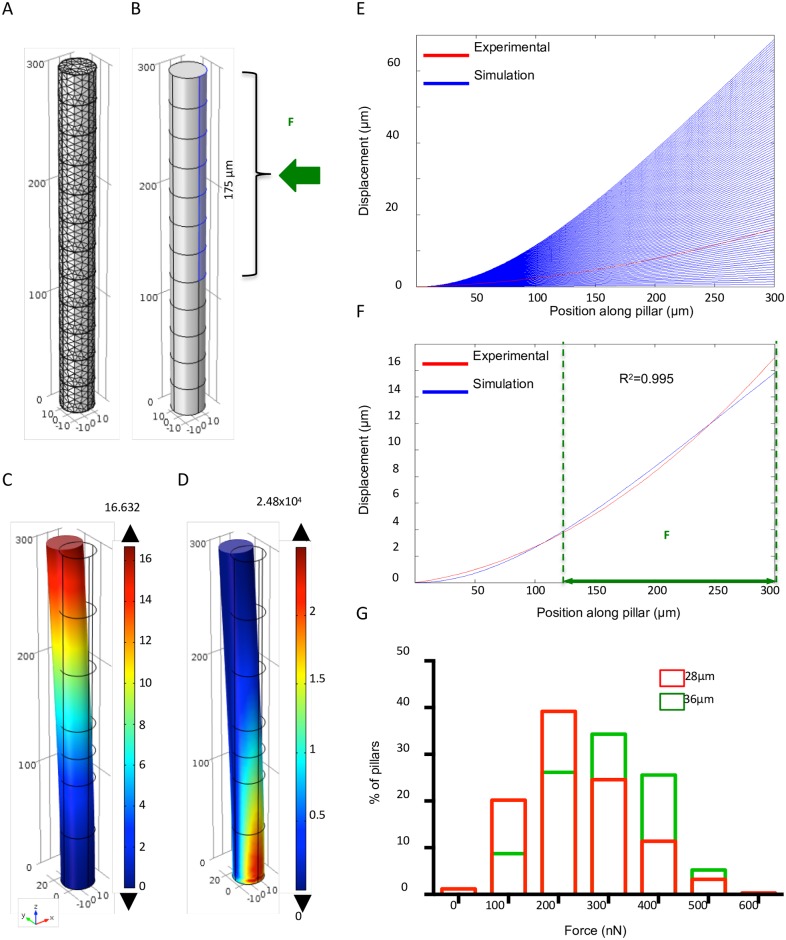

Fig 4. Determination of the forces exerted by growing spheroids based on pillar deflection using the finite-element method analysis.

(A) Fine tetrahedral meshing of the whole micropillar. (B) 3D model of the cylindrical micropillar with the introduced geometrical and material parameters. The uniform unidirectional boundary of the force (F) load on the upper 175 μm of the pillar length is highlighted in blue. (C) Pillar deflection: the highest deformation is at the pillar top (colour code unit: μm). (D) Von Mises stress for the deformed pillar showing the highest stress at the fixed bottom (colour code unit: N/m2). (E) Abacus of pillar deflection curves according to the range of applied forces (blue). The deformation curve obtained using the experimental data for one pillar is shown in red. (F) Comparison of the experimental (red) and best-fitted simulated curve (blue) for one pillar indicates that the best match corresponds to an applied force of 230nN. The vertical green dashed lines indicate the horizontal force load domain. (G) Distribution of the forces exerted on the pillars by spheroids at day 4 after insertion in the microdevice (n = 342 micropillars from 21 microdevices with pillar diameter = 28 μm, and n = 172 micropillars from 12 microdevices with pillar diameter = 36 μm).