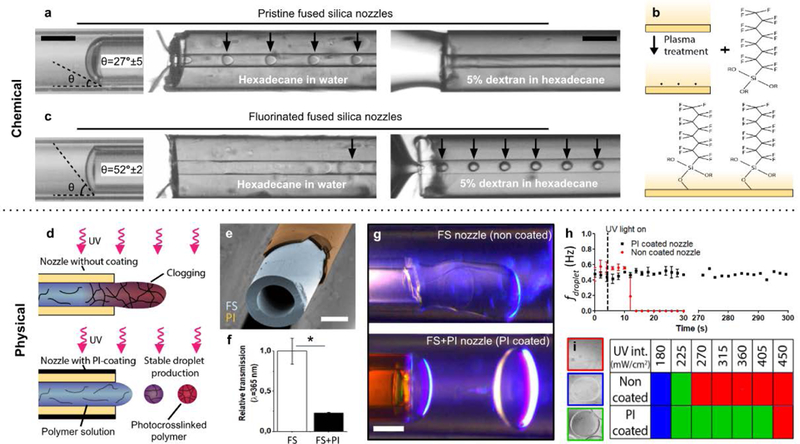

Figure 4. Chemical and physical optimization of exchangeable nozzles to enable the processing of polymers solutions.

(a) Pristine fused silica nozzles were hydrophilic, which readily enabled the formation of O/W emulsions, but impaired the formation of polymer-laden W/O emulsions such as dextran solution in hexadecane. (b) Chemically treating the fused silica with fluorinated silane (c) resulted in less hydrophilic nozzles that were compatible with the production of polymer-laden W/O emulsions. (d-e) Alternatively, fused silica (FS) nozzles could be physically modified with a UV-protective polyimide (PI) coating to prevent nozzle clogging during processing of photocrosslinkable polymers. (f) The polyimide coating reduced the relative UV transmission by more than 4-fold and enabled (g,h) continuous and stable production of photocrosslinked polymer microspheres under UV irradiation by preventing nozzle clogging (i) over a wide range of UV intensities as compared to non-coated nozzles. Nozzle clogging, incompletely photocrosslinked PEGDA, and completely photocrosslinked PEGDA are indicated with red, blue, and green squares, respectively. Scale bars indicate 200 μm. * indicates significance with p <0.01.