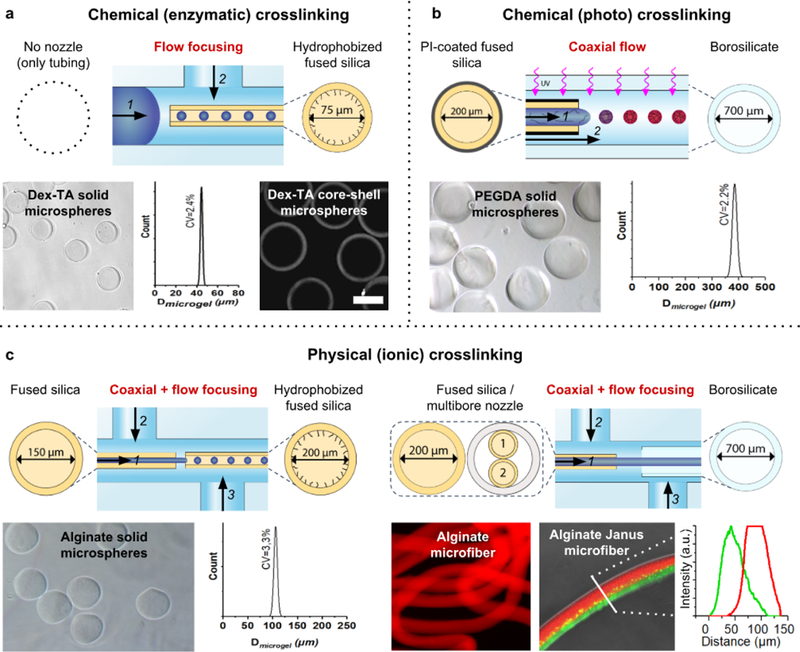

Figure 5. Various examples of monodisperse micromaterials produced using the multifunctional 3D microfluidic device with different optimized nozzle configurations.

(a) Flow focusing an enzymatically crosslinkable Dex-TA and HRP containing solution (1) in hexadecane with Span 80 (2) using a fluorinated fused silica nozzle enabled the production of monodisperse solid dextran-based microspheres. (b) Coaxially flowing a photocrosslinkable PEGDA and I2959 containing solution (1) in hexadecane with Span 80 (2) using a polyimide-coated fused silica nozzle enabled the production of monodisperse PEG-based microspheres. (c) Focusing coaxially flowing alginate (1) and PEG (2) containing solutions in a calcium chloride containing solution (3) using a combination of single and multibore capillaries enabled the production of monodisperse simple and Janus type microfibers. Scale bar indicates 200 μm.