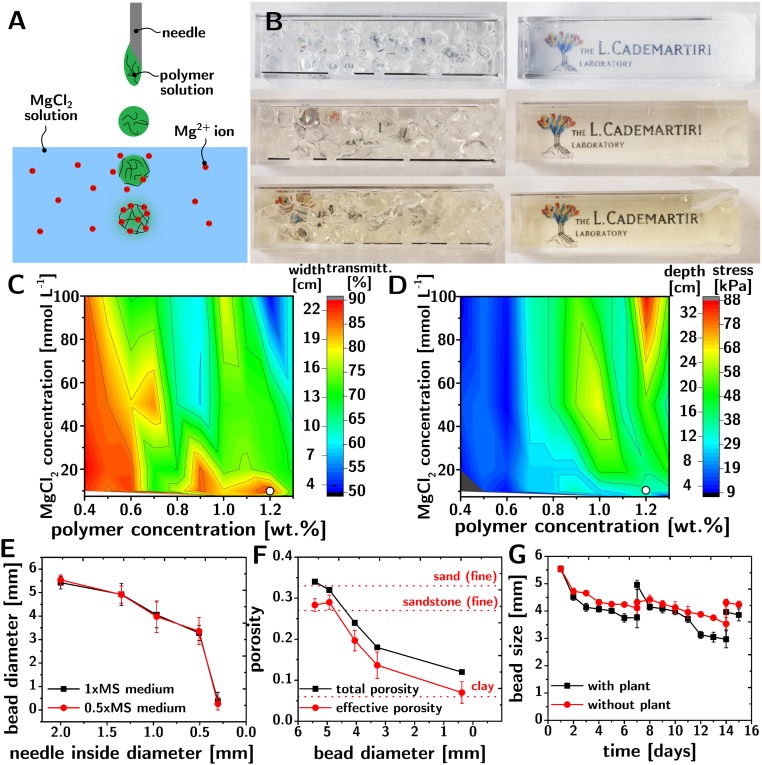

Fig. 1.

Fabrication and physical properties of hydrogel-based TS. (A) Sketch of the spherification process to make the hydrogel beads. (B) TS before (Left) and after (Right) saturation with nutrient growth media [0.5× Murashige and Skoog medium (Top), lysogeny broth (Middle), and soil extract (Bottom)]. The logo behind the cuvette is not visible before saturation but becomes clearly visible upon saturation of the TS. (C) Transmittance of TS (at 1,080 nm, in 0.5× MS) as a function of the concentration of the polymer and MgCl2 solutions used during spherification. The colormap also shows the length of the optical path that leads to 10% transmittance at 1,080 nm. (D) Collapse stress of TS (filled with 0.5× MS) as a function of the concentration of the polymer and MgCl2 solutions used during spherification. The colormap also shows the thickness of TS that would collapse at its bottom. (E) Bead size as a function of the inner diameter of the nozzle used during spherification. (F) Total and effective porosity of TS as a function of the size of the beads. (G) Shrinkage of the beads as a function of time (with and without plants) and their recovery upon saturation with media on days 7 and 14.