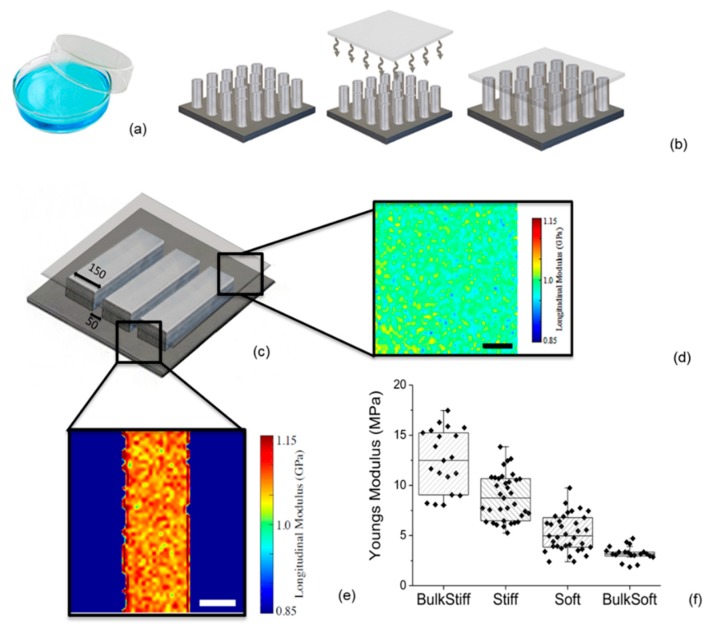

Figure 1.

Design of complex mechanical PDMS substrates. (a–b) Schematic of substrates designed for this study. Bulk substrates were fabricated by simply pouring PDMS of the desired rigidity in petri dishes (a). For the durotactic substrates (b): a thin membrane of PDMS of controlled compliance is bonded on a topographically patterned stiff PDMS support, which generates stiffness cues at the substrate surface. The substrates used in this study included ‘line substrates’(c), and ‘flat substrates’. Brillouin microscopy was used to probe the surface longitudinal modulus, M′, for the PDMS (d,e). The thin membrane composed of 50:1 base to curing agent showed uniformity of measure with M′ = 0.988 ± 0.015 GPa (d); while the micropattern line of 150 µm displayed a longitudinal modulus of M′ = 1.070 ± 0.016 GPa, Scale bar: 100 µm. (e) Young’s elastic modulus of the different stiff and soft substrates assessed by AFM nanoindentation measurements (f). Statistical significance is p < 0.05, assessed by Tukey one-way ANOVA test.