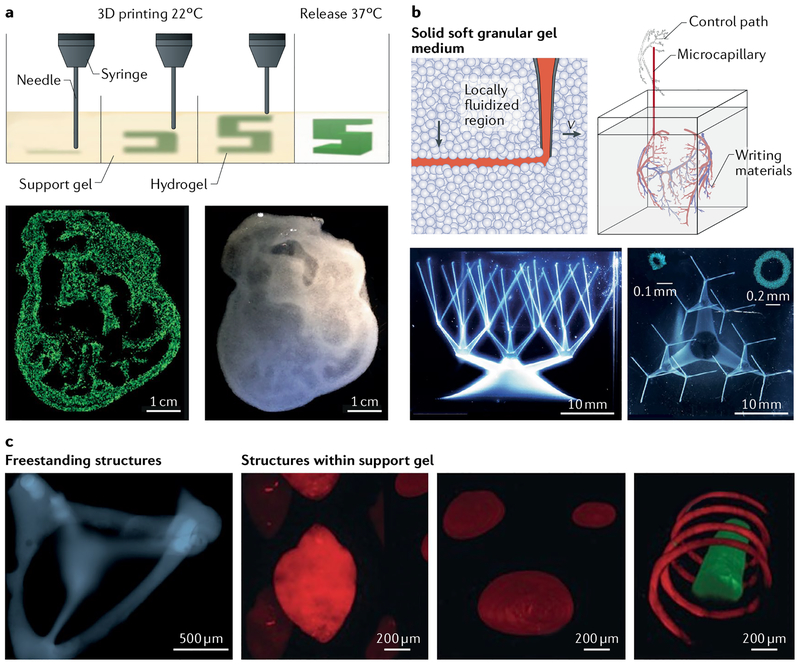

Fig. 4 |. Bioprinting in support materials.

Self-healing hydrogels can be used as support media for bioprinting to enable the 3D fabrication of structures. a | A gelatin slurry can be used for the fabrication of hydrogel structures with large void spaces, for example, heart constructs. The hydrogel (green) is extruded and crosslinked within the gelatin slurry support (yellow). The 3D object is then released through melting of gelatin at 37 °C. Using this method, an embryonic chicken heart can be fabricated on the basis of a 3D computer-aided design model. The bioprinted tissue construct made using fluorescent alginate (green) exhibits the same internal trabecular structure as an embryonic chicken heart. b | A granular medium composed of carbomer microgels enables 3D printing of multiscale hierarchical structures, for example, continuous branched tubular networks of hollow vessels. The network of hollow tubes shown in the microscopy images was printed using polyvinyl alcohol, starting from a 25 mm diameter circular base and tapering to 27 capillaries with a diameter of 100 μm and a wall thickness of 100 μm. The insets show confocal cross sections. c | Hydrogels crosslinked by non-permanent, shear-thinning and self-healing bonds support the printing of high-resolution structures. Support material or printed ink can be removed after processing to produce complex structures that are freestanding or that contain voids and channels. The confocal microscopy images show a freestanding 3D tetrahedron made of photocrosslinked methacrylate-modified hyaluronic acid (blue), a rhodamine-labelled spherical structure (red) in an unlabelled support hydrogel and a fluorescein-labelled filament (green) with a rhodamine-labelled spiral (red) in an unlabelled support hydrogel. Panel a is adapted from REF32, CC-BY-4.0. Panel b is adapted from REF33, CC-BY-4.0. Panel c is adapted with permission from REF34, John Wiley and Sons.