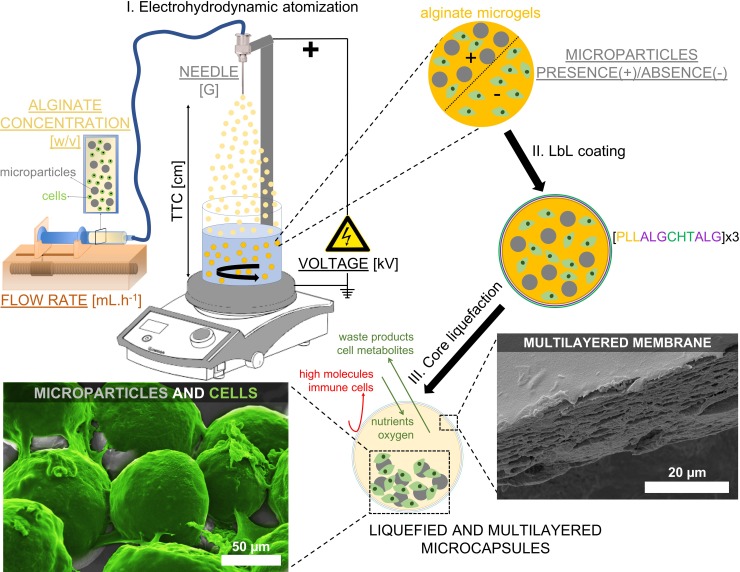

Fig 1. Schematic representation of the production of liquefied and multilayered microcapsules for tissue regeneration.

(I) An alginate solution containing the cargo components, namely cells and microparticles, is electrosprayed by the electrohydrodynamic atomization (EHDA) process. The influence on the microgels diameter of different parameters of the EHDA process is tested, namely the voltage (kV), the flow rate (mL.h-1), the needle diameter (G), the distance between the tip of the needle to the collector (TTC, cm), the presence (+) or absence (-) of microparticles, and the alginate concentration (w/v). The different parameters tested are underlined. (II) Microgels are then used as templates to produce a multilayered membrane by Layer-by-Layer (LbL) technique using poly(L-lysine) (PLL), chitosan (CHT), and alginate (ALG) polyelectrolytes (n = 12-layers). (III) Ultimately, microgels are immersed in ethylenediaminetetraacetic acid, and liquefied and multilayered microcapsules are obtained. The LbL membrane of microcapsules is permeable to essential molecules for cell survival, while avoiding the entrance of high molecules and immune cells. On the other hand, the microparticles dispersed within the liquefied environment provide adhesion sites required for multiple cellular processes. Scanning electron microscopy images show a LbL membrane (adapted from reference [7]), and L929 cells (colored in green) adhered to the surface of microparticles (adapted from reference [8]).