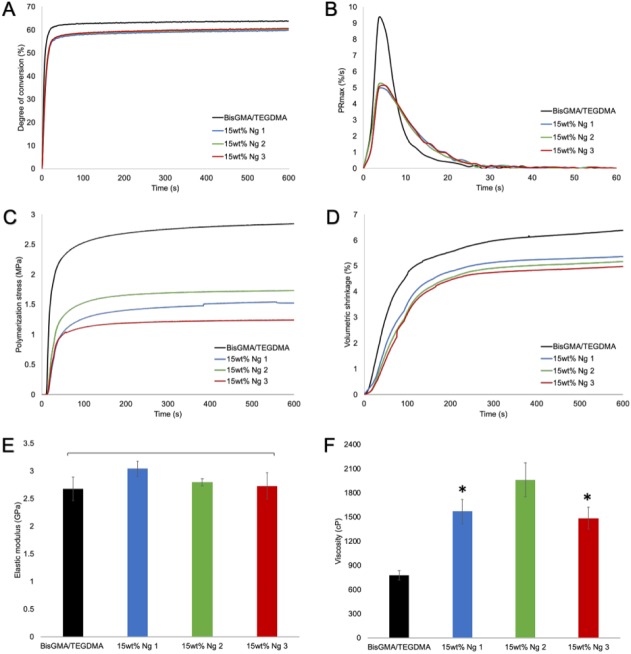

Figure 2.

Conversion and property development in nanogel-modified resins. (A) Polymerization kinetics of BisGMA/TEGDMA shows slightly diminished degree of conversion when resin is loaded with 15 wt% of nanogels. (B) In contrast, the maximum polymerization rate is noticeably lower for nanogel systems. (C) The polymerization stress with nanogel loading is approximately half that of the control resin, and (D) it accompanies a decrease in volumetric shrinkage as well. (C) The smaller, lower Tg nanogel additive tended to provide a greater degree of stress reduction than the larger, higher Tg nanogel analog. (E) Notably, the flexural modulus of nanogel-loaded resins is similar to control. (F) Incorporation of nanogel increased resin viscosity significantly, especially in the case of the larger Ng 2. (E, F) Values are presented as mean ± SD. *P < 0.05. BisGMA/TEGDMA, bisphenol A glycidyl dimethacrylate/triethylene glycol dimethacrylate; Ng, nanogel; Tg, glass transition temperature.