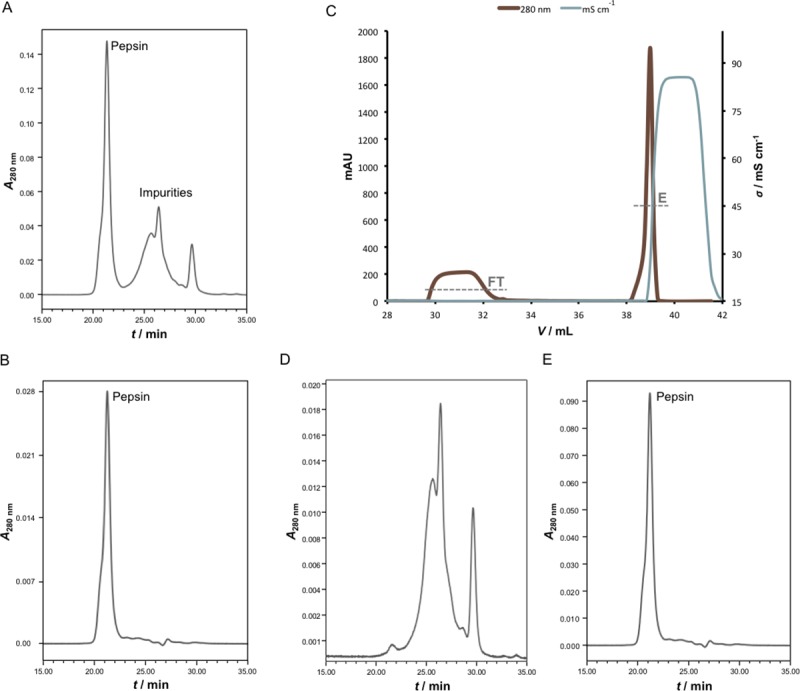

Fig 4. Verification of pepsin removal by the final polishing procedure.

SEC analysis of pepsin sample on TSK-Gel G3000SWXL column (7.8 × 300 mm) with 0.1 M phosphate-sulphate running buffer, pH 6.6, at a flow rate of 0.5 mL min-1 prior (A) and post-diafiltration on a 50 kDa membrane (B). Anion-exchange chromatography of pepsin sample on CIM QA disk (V = 0.34 mL) with MES + 0.15 M NaCl buffer, pH 5.0, at a flow rate of 2 mL min-1 (C). Enzymatically active material was retained on the column and it was subsequently eluted with 100% yield. Manufacturing by-products that affect pepsin purity lacked capability of binding. Size-exclusion chromatography of flow-through (D) and elution fraction (E) from anion-exchange chromatography in (C). Detection: UV at 280 nm.