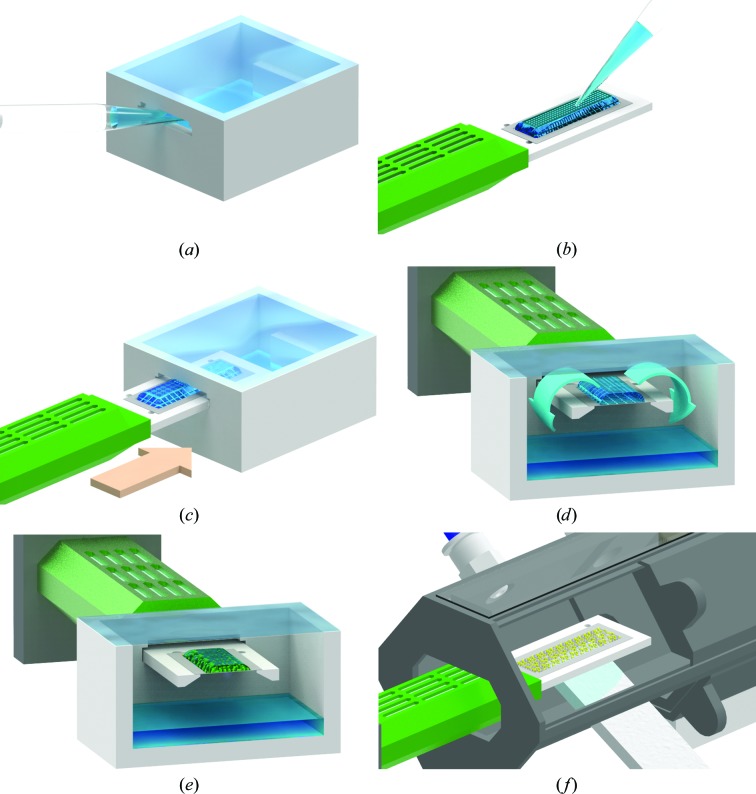

Figure 4.

Procedure for on-chip crystallization using Roadrunner II chips. (a) The top opening of the crystallization chamber is sealed with transparent sticky tape and the chamber is subsequently filled with 5–10 ml reservoir solution through the side opening. (b) 100 µl of the protein–precipitant mixture is applied to the chip and carefully spread over the whole chip area using a pipette tip or a rectangular cover slide. (c) The chip holder is then inserted through the side opening of the chamber and the remaining cleft between the chamber and chip holder is sealed with Parafilm to minimize evaporation. (d) In the sealed chamber, the vapor-diffusion process leads to a decrease in the drop volume. (e) Crystal growth on the chip can be monitored by light microscopy using top light illumination. (f) After crystal growth has finished, the chip is removed from the crystallization chamber. Under a stream of humidified air, as shown here in a so-called ‘chip-loading station’, the mother liquor is carefully and thoroughly removed through the pores of the chip with a soft tissue. This handling step can be observed through the transparent window on top of the loading station. Afterwards, the humidor is slid over the chip and the naked crystals can be safely transported to the beamline for data collection.