Table 1.

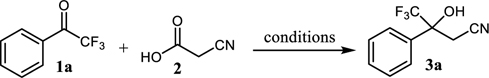

Optimization of the cyanomethylation of 2,2,2-trifluoroacetophenone.[a]

| |||||

|---|---|---|---|---|---|

| Entry | Base (mol%) | Solvent | Time (h) | Temp (°C) | Yield (%)[b] |

| 1 | DBU (50) | THF | 42 | 25 | 49 |

| 2 | Et3N (50) | THF | 42 | 25 | 45 |

| 3 | DIPEA (50) | THF | 42 | 25 | 29 |

| 4 | DABCO (50) | THF | 42 | 25 | 13 |

| 5 | TMEDA (50) | THF | 42 | 25 | 23 |

| 6 | DMAP (50) | THF | 42 | 25 | 36 |

| 7 | Barton’s base (50) | THF | 42 | 25 | 42 |

| 8 | K2CO3 (50) | THF | 42 | 25 | <5 |

| 9 | Cs2CO3 (50) | THF | 42 | 25 | 9 |

| 10 | None | THF | 42 | 25 | nr |

| 11 | Et3N (50) | CH2Cl2 | 48 | 25 | <5 |

| 12 | Et3N (50) | 1,4-dioxane | 48 | 25 | 27 |

| 13 | Et3N (50) | toluene | 48 | 25 | <5 |

| 14 | Et3N (50) | CH3CN | 48 | 25 | 8 |

| 15 | Et3N (50) | CH3OH | 48 | 25 | <5 |

| 16 | Et3N (50) | H2O | 48 | 25 | nr |

| 17 | Et3N (10) | neat, MW | 0.75 | 100 | 89 |

| 18 | Et3N (50) | THF | 16 | 60 | 99 |

| 19 | Et3N (20) | THF | 21 | 60 | 98[d] |

| 20[c] | Et3N (20) | THF | 24 | 60 | 98[d] |

| 21[c] | Et3N (10) | THF | 36 | 60 | 91 |

Conditions: 0.3 mmol of 1a, 0.9 mmol of 2, 1 mL of solvent.

By NMR analysis.

Two equivalents of 2 were used. The reaction is slow and takes 3 days with 1.5 equivalents of 2.

Isolated yields.