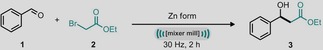

Table 2.

Mechanochemical Reformatsky reaction using different zinc forms.

| Entry | Zn form | Supplier | Conv. [%][a] | Yield [%][a] |

|---|---|---|---|---|

| 1 | zinc granular, 20–30 mesh | Sigma–Aldrich | 97 | 81 |

| 2 | zinc granular, 20 mesh | Sigma–Aldrich | 99 | 72 |

| 3 | zinc foil, 0.25 mm thick, 99.9 % | Sigma–Aldrich | 99 | 77 |

| 4 | zinc dust, <10 mm | Sigma–Aldrich | 98 | 80 |

| 5 | zinc puriss, ACS reagent, >99.9 % | Sigma–Aldrich | 91 | 66 |

| 6 | zinc shot, 10 mm dia., 2 mm thick, 99.99 % |

Sigma–Aldrich | 87 | 53 |

| 7 | zinc flake, ca. 325 mesh, 99.9 % | Alfa Aesar | 99 | 87 |

| 8 | zinc wire, 0.04 in dia., 99.95 % | Alfa Aesar | 95 | 75 |

| 9 | zinc powder, 6–9 μm, 97.5 % | Alfa Aesar | 99 | 83 |

| 10 | zinc metal powder | Fisher Scientific | 98 | 68 |

| 11 | zinc, ≥99%, mossy | Acros | 96 | 73 |

| 12 | zinc foil, 0.38 mm | BDH chemicals | 99 | 73 |

Reaction conditions: benzaldehyde (1 mmol), ethyl 2‐bromoacetate (1.2 mmol), zinc form as specified (2 equiv), mixer mill, 30 Hz, 2 h. [a] Conversion and yield were determined by 1H NMR spectroscopy with mesitylene as an internal standard.