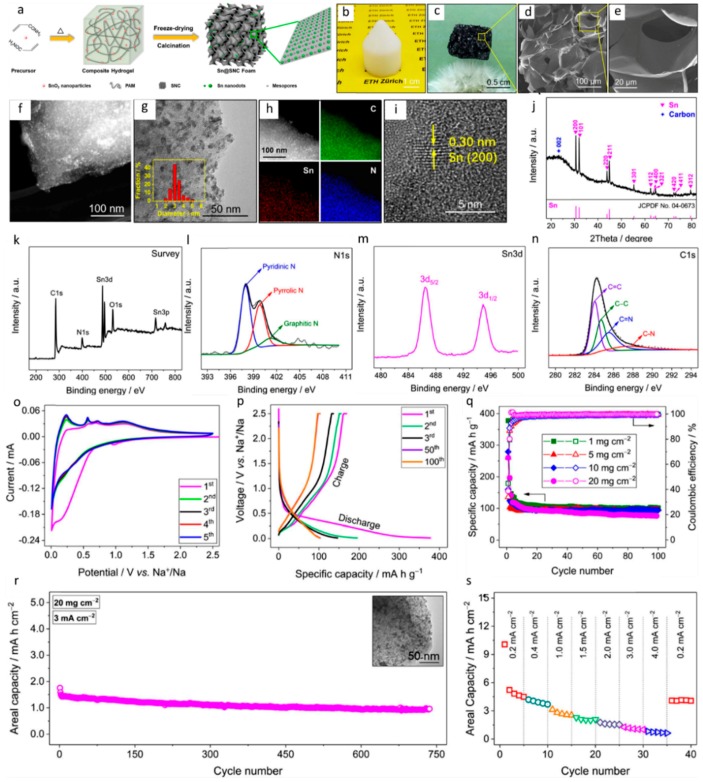

Figure 2.

Structural characterization and electrochemical performance analysis of Sn-based alloy (Sn@SNC) as an anode in SIBs: (a) Synthetic procedure of Sn@SNC foam from SnO2/polyacrylamide composite hydrogel. (b,c) Photographs of SnO2/PAM composite hydrogel and hierarchically porous Sn/SNC foams. (d,e) SEM image of Sn@SNC structures show a 3D interconnected microporous structure and confirm the sheet-like carbon structure. (f,g) STEM & TEM images confirm the uniform distribution of Sn nanodots in the SNC. Inset shows the diameter of Sn nanodots are ~3.2 nm. (h) STEM with element mappings also confirm the homogenous distribution of the Sn nanodots throughout the SNC. (i) HRTEM image of Sn@SNC shows the lattice spacing of 0.30 nm, distinctive to the (200) plane of metallic Sn. (j) XRD patterns of the Sn@SNC shows the co-existence of metallic Sn and amorphous SNC. (k–n) XPS survey spectrum demonstrates the presence of C, N, and Sn, confirming the disordered structure and successful doping of N in SNC. (o) CV curves for the initial five cycles of Sn@SNC at a scanning rate of 0.1 mV s−1. (p) Voltage profiles of Sn@SNC at a current density of 100 mA g−1 delivering an initial discharge capacity of 377.6 mAh g−1 with 44.7% coulombic efficiency. (q) The Sn@SNC foams deliver a specific capacity of 101.8 mAh g−1 at a mass loading of 1 mg cm−2 after 100 cycles at a current density of 100 mA g−1. At a higher mass loading of 20 mg cm−2, the anode shows a capacity decrease of 25% with a specific capacity of 76.3 mAh g−1. (r) The Sn@SNC anode shows a good cycling ability, delivering a high reversible areal capacity of 1 mAh cm−2 at a current rate of 3 mA cm−2 after 700 cycles. (s) Rate capability of Sn@SNC foams (mass loading = 20 mg cm−2) at various current densities. A reversible areal capacity of 0.6 mAh cm−2 is achieved at a high current of 4 mA g−1. Reprinted with permission from [75]. Copyright 2018 Elsevier.