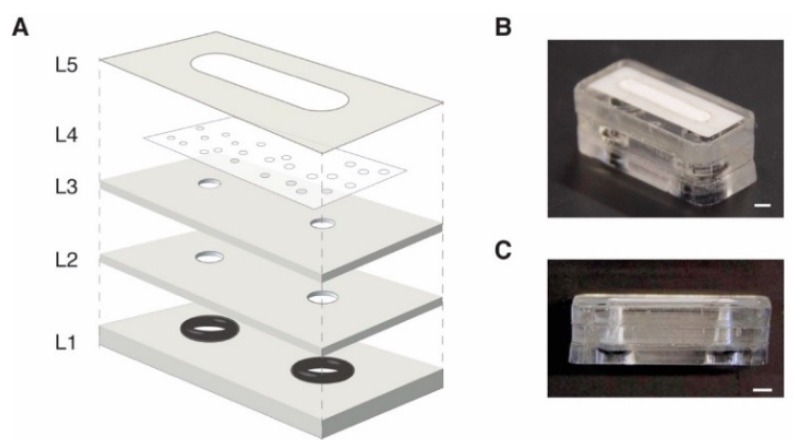

Figure 1.

(A) Exploded view of the RID module. L1–L3 are laser cut from polymethymethacrylate (PMMA). L1 and L2 have pressure sensitive adhesive on the top face to facilitate layer-to-layer lamination. L3 is the tubing stop layer used to prevent damage to L4, the porous, hydrophobic PTFE membrane. L5 is laser cut from polyester film and has PSA on the bottom surface to seal the edges of the PTFE membrane and prevent leakage. After assembly, an O-ring is inserted into the access ports in L1 to provide simple push-to-connect compression sealing to interface the device with tubing for fluid routing. (B) Isometric image of assembled RID module. Scale bar = 2 mm. (C) Side view of assembled device. Scale bar = 2 mm.