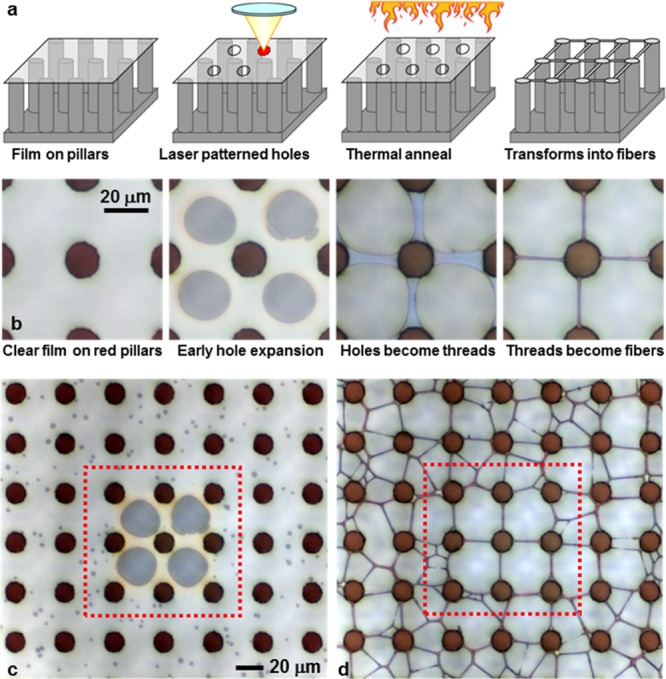

Figure 1.

STP: method and demonstration of the transformation of a polymer thin film (the 80 nm thick region of film 6) into patterned arrays of polymer fiber air bridges. (a) Three-dimensional schematic view of the method. (b) Photographs of the film before patterning and at various stages of the thermal anneal as the film transforms from holes into fibers. (c) Wider field of view of the film in (b) during early hole expansion. The unpatterned areas (outside the dotted box) have many randomly nucleated holes. The temperature has just reached 97 °C when the nuclei first appear. In (d) where the temperature has reached 125 °C, the nuclei expand to produce a random pattern of fibers, while the prepatterned areas (inside the dotted box) have transformed into a well-ordered array of fibers in (d).