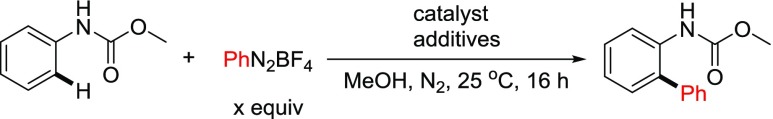

Table 1. Optimization of the Reaction Conditionsa.

| entry | catalyst (10 mol %) | additive | x equiv | yield (%) of 3b |

|---|---|---|---|---|

| 1 | Pd(MeCN)4BF4 | 4 | 26 | |

| 2 | Pd(MeCN)2(OTf)2 | 4 | 27 | |

| 3 | Pd(MeCN)2(OTs)2 | 4 | 34 | |

| 4 | Pd(OAc)2 | 4 | 52 | |

| 5 | Pd(OAc)2 | Ru(bpy)3Cl2·H2O | 4 | 55 |

| 6 | Pd(TFA)2 | 4 | 58 | |

| 7 | Pd(TFA)2 | PTSA (2 equiv) | 4 | 64 |

| 8 | Pd(TFA)2 | AgOAc (1 equiv) | 4 | 50 |

| 9 | Pd(TFA)2 | Ag2CO3 (1 equiv) | 4 | 30 |

| 10 | Pd(TFA)2 | 2 | 38 | |

| 11c | Pd(TFA)2 | 4 | 68 | |

| 12d | Pd(TFA)2 | 4 | 15 | |

| 13e | Pd(TFA)2 | 4 | 20 | |

| 14 | Pd/C | 4 | <5% | |

| 15f | Pd2dba3 | 4 | <5% |

All reactions were carried out in 0.1 mmol scale.

Yields refer to here are isolated yields.

Two equiv of aryldiazonium salt added different of 30 min interval.

Isopropanol used as a solvent.

THF used as a solvent.

Homocoupling product was isolated.