Table 1. Optimization of Reaction Conditionsa.

| yield

(%)b |

|||||

|---|---|---|---|---|---|

| entry | catalyst (mol %) | additive (equiv) | 3aa | 3aa′ | 4a |

| 1 | CuBr (30) | 22 | 19 | 18 | |

| 2 | CuBr (50) | 13 | 25 | 38 | |

| 3 | CuBr (100) | trace | 34 | 58 | |

| 4c | CuBr (100) | 80 | |||

| 5 | CuBr (30) | TBAB | 27 | 33 | Trace |

| 6 | CuI (30) | TBAB | 25 | 14 | Trace |

| 7 | CuBr2 (30) | TBAB | 31 | 12 | Trace |

| 8 | CuCl2·2H2O (30) | TBAB | 28 | 35 | Trace |

| 9 | Cu(OAc)2·H2O (30) | TBAB | 23 | 27 | Trace |

| 10 | Cu(OCOCF3)2 (30) | TBAB | 28 | 40 | Trace |

| 11 | CuSO4·5H2O (30) | TBAB | 30 | 36 | Trace |

| 12 | TBAB | ||||

| 13d | Cu(OCOCF3)2 (30) | TBAB | |||

| 14e | Cu(OCOCF3)2 (30) | TBAB | 24 | trace | Trace |

| 15f | Cu(OCOCF3)2 (30) | TBAB | 17 | trace | Trace |

| 16g | Cu(OCOCF3)2 (30) | TBAB | |||

| 17 | Cu(OCOCF3)2 (30) | TBAI | 27 | 40 | trace |

| 18 | Cu(OCOCF3)2 (30) | TBAC | 26 | 43 | trace |

| 19h | Cu(OCOCF3)2 (30) | TBAB | 31 | 21 | trace |

| 20i | Cu(OCOCF3)2 (30) | TBAB | 26 | 46 | trace |

| 21i,j | Cu(OCOCF3)2 (30) | TBAB | 31 | 40 | trace |

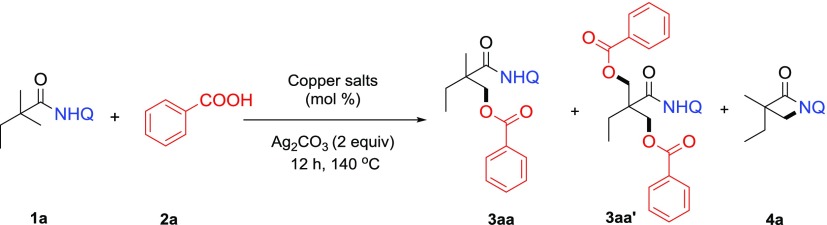

Reaction conditions: 1a (0.1 mmol), 2a (0.2 mmol), Ag2CO3 (2 equiv), additive (1 equiv), solvent (2 mL): toluene/DMF (1:1), in air.

Isolated yield.

Without 2a, 8 h.

Without Ag2CO3.

AgOAc (2 equiv).

AgOCOCF3 (2 equiv).

K2S2O8 (2 equiv).

130 °C.

150 °C.

Under Ar atmosphere.