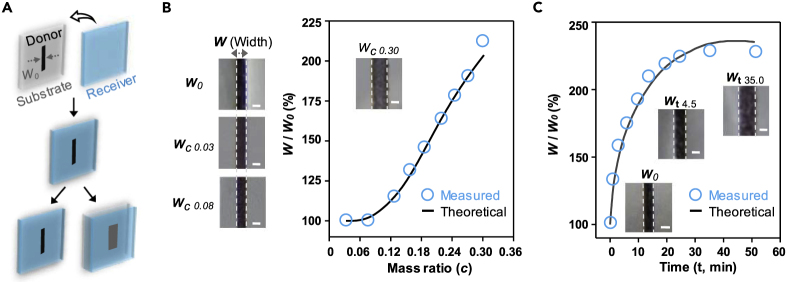

Figure 3.

Pattern Size Tuning of Liquid-Liquid Printing

(A) Schematic diagram of the diffusion model. W0 is the original width of the pattern line.

(B) Mass ratio of the receiver solvent to the overall receiver, i.e., c, regulates the printing line width. It is determined by mass flow rate (Table S6). The liquid receiver is PVDF (acetone-DMAC) (Figure S4A), whereas the liquid donor is black neutral pen ink (Figure S4B). Wc is the width of the line for a special c. The blue circles are experimental data for the ratio between Wc and W0, whereas the black curve represents the model results. Scale bars, 0.5 mm. The experiments are conducted at 25°C and 35% ± 3% relative humidity.

(C) The diffusion time regulates the printing line width. Wt is the width of the line at a certain time (t). The blue circles are experimental data for the ratio between Wt and W0, whereas the black curve represents the theoretical simulation results. Scale bars, 0.5 mm.