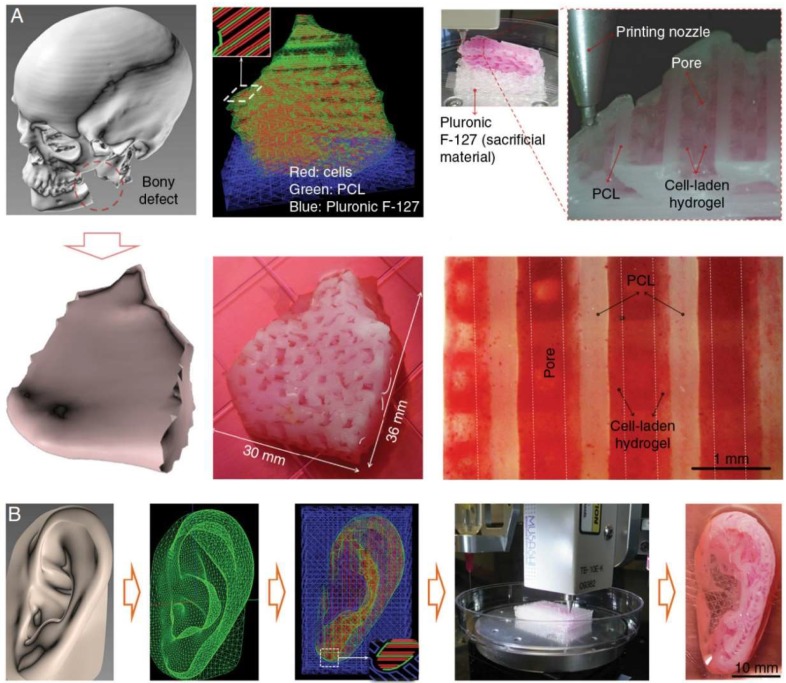

Figure 4.

Craniofacial bone and cartilage reconstruction using PCL as a material for 3D printing. (A) Mandibular bone reconstruction. 3D defect model was obtained from the craniofacial CT image data followed by the design of dispensing paths of cells, PCL, and Pluronic F-127 with self-developed software. Multiple cartridges used to deliver and pattern the above ink materials were connected to a microscale nozzle, which dispensed the materials according to the design during 3D printing process. PCL was printed as the framework and the cell-laden hydrogel were dispensed to fill the pores, while Pluronic F-127 were used as sacrificing materials. The osteogenic potential of the scaffold was confirmed by Alizarin Red S staining after being cultured in osteogenic medium for 28 d. (B) Auricle cartilage construction. Similarly, a 3D computer-assisted (CAD) model of auricle can be developed from CT or MRI image data and generate a visualized motion program consisting of a command list for XYZ stage movements and air pressure actuation for 3D printing. The concentrations of different ingredients for 3D printing can be optimized by in vitro culture and related tests. Reproduced with permission from [90].