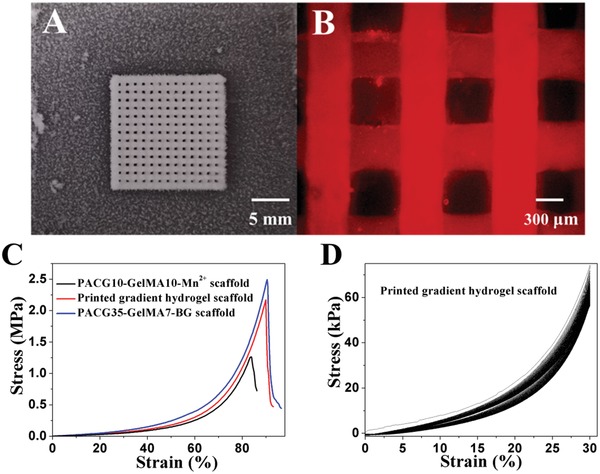

Figure 4.

A) A photograph of ACG‐GelMA hydrogel scaffold printed by air‐extrusion method assisted with a low‐temperature receiver before UV light irradiation; B) microscope image of PACG‐GelMA hydrogel scaffold after UV light irradiation and reaching swelling equilibrium (stained with rhodamine); C) compressive stress–strain curves of the printed porous PACG10‐GelMA10‐Mn2+ hydrogel scaffolds, PACG35‐GelMA7‐BG hydrogel scaffolds, and gradient hydrogel scaffolds; D) cyclic compressive stress‐strain curves for the printed gradient scaffold (the top three layers were printed by PACG10‐GelMA10 hydrogel, and the bottom nine layers were printed by PACG35‐GelMA7‐BG hydrogel under a maximum strain of 30%. The cycle numbers were set as 100.