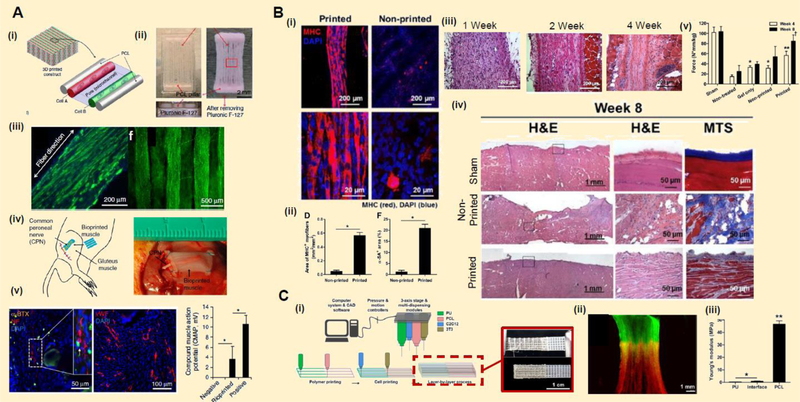

Figure 7.

Muscle biofabrication using EBB. (A) Schematic of 3Dbioprinted cell-laden hydrogels flanked by PCL polymer supporting filaments (i). Optical image of 3D-bioprinted muscle before (left) and after (right) the removal of fugitive ink, Pluronic F127 (ii). D7 live/dead analysis of myoblasts encapsulated in a composite fibrinogen-gelatin-hyaluronan structure, demonstrating cell alignment along the length of the printed fiber (iii). Subcutaneous implantation of bioprinted muscle facilitates host innervation, vascularization, and partial restoration of musclegenerated action potentials (iv-v). (B) D7 immunohistochemical images of myofiber formation depict bioprinted muscle constructs enhance myoblasts alignment and increase myogenic-specific marker (α-sarcomeric actin and myosin-heavy chain) expression in comparison to nonprinted muscle constructs (i-ii). Histological analysis of muscle construct explants after 2 weeks demonstrates an increase in cell density overtime (iii). H&E and MTS analysis on muscle construct explants after 8 weeks reveals comparable muscle volume retention and morphology in bioprinted tissues and sham models in relation to non-printed tissue (iv). Tetanic force of bioprinted muscle construct displayed the greatest recovery in muscle function in comparison to non-printed muscle constructs (v). (C) Schematic of 3D muscle-tendon unit printing system and optical images of the fabricated structure under tension (top) and at rest (bottom) (i). Fluorescently-labelled NIH/3T3 fibroblasts (red ) and C2C12 myoblasts (green) imaged after 7 days in culture presenting a well-defined intermediate zone (yellow) between fabricated muscle and tendon (ii). Mechanical properties of distinct acellular MTU regions under tension (iii). (Kang et al., 2016; Kim et al., 2018; Merceron et al., 2015)

7A: Kang HW, Lee SJ, Ko IK et al. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nature Biotechnology. 2016;34(3):312322 doi:10.1038/nbt.3413

7B: Kim JH, Seol YJ, Ko IK et al. 3D Bioprinted Human skeletal Muscle Contructs for Muscle Restoration. Scientific Reports. 2018;8:12307. doi:10.1038/s41598–018-29968–5

7C: Merceron TK, Burt M, Seol YJ et al. A 3D bioprinted complex structure for engineering the muscle-tendon unit. Biofabrication. 2015;7:035003. doi:10.1088/1758-5090/7/3/035003