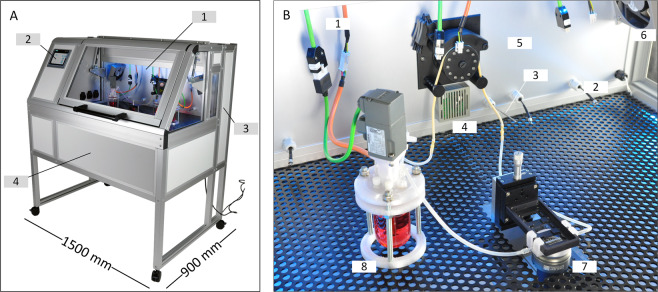

Figure 2.

Hardware setup of cell expansion platform. (A) A tailor-made incubator system was constructed to provide appropriate culture conditions for human induced pluripotent stem cell suspensions. The heart of the incubator is the incubated space (1) that accommodates the suspension culture vessels. The incubator atmosphere control, liquid-handling device settings, impeller agitation speed and data management is adjustable via human machine interface (2). The process control equipment and sensor transmitters are situated at the backside compartment of the incubator (3). The in situ imaging microscope is incorporated into the lower compartment (4). (B) The incubator was designed to operate multiple miniature CSTRs in parallel. Therefore, motor power cables are available to run three reactors simultaneously (1). Equally, optical oxygen measurement and pH measurement is available for each reactor in operation (2). The incubator atmosphere was set to 37 °C and 5% CO2 with the aid of temperature (3) and carbon dioxide (4) sensors. The incubation chamber was tempered by heating foils attached to the rear panel of the incubator (5). Fans (6) to either side of the incubation chamber ensured constant air circulation. Real-time imaging of cell aggregates was achieved by passing a portion of the cell suspension from the reactors across a fixed microscope (7). CSTRs (8) were placed freely inside the incubator.