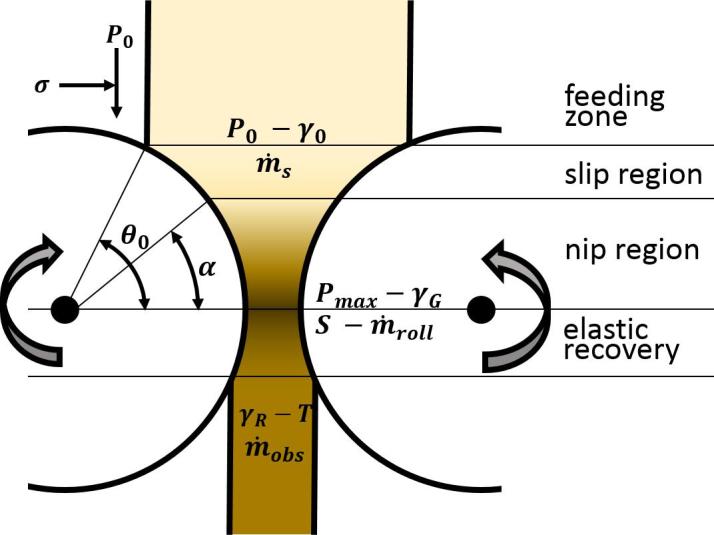

Fig. 2.

Schematic diagram of the compaction process showing the feeding zone and the nip and slip regions. The powder has the maximum density at the gap. Past the roller gap, there is a region of elastic recovery where ribbon thickness T increases while reducing the ribbon density to its final value . The mass flow can be predicted in the feeding zone using either the screw mass flow rate () or the gap geometry and the roller speed (). Experimentally, it is the throughput observed after the ribbon relaxation ().