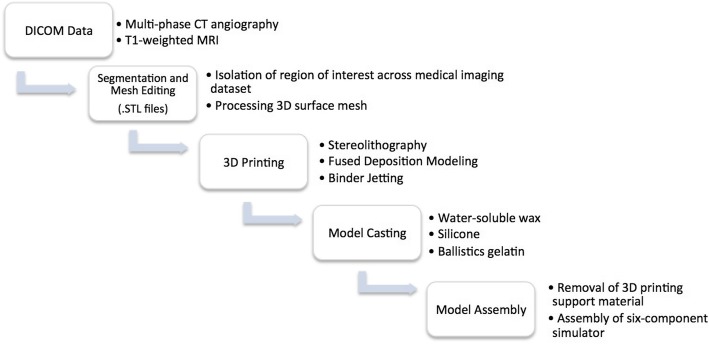

Fig. 1.

Flowchart presents the workflow for simulator development. Initially, DICOM data was imported into segmentation software in which the region of interest was isolated. The 3D rendered mesh was processed. The generated .STL files were assigned to a 3D printer to print anatomical models and moulds. The moulds were used to cast soft-tissue models in various materials. Post-print processing involved the removal of 3D printing support materials and assembly of the six-component simulator