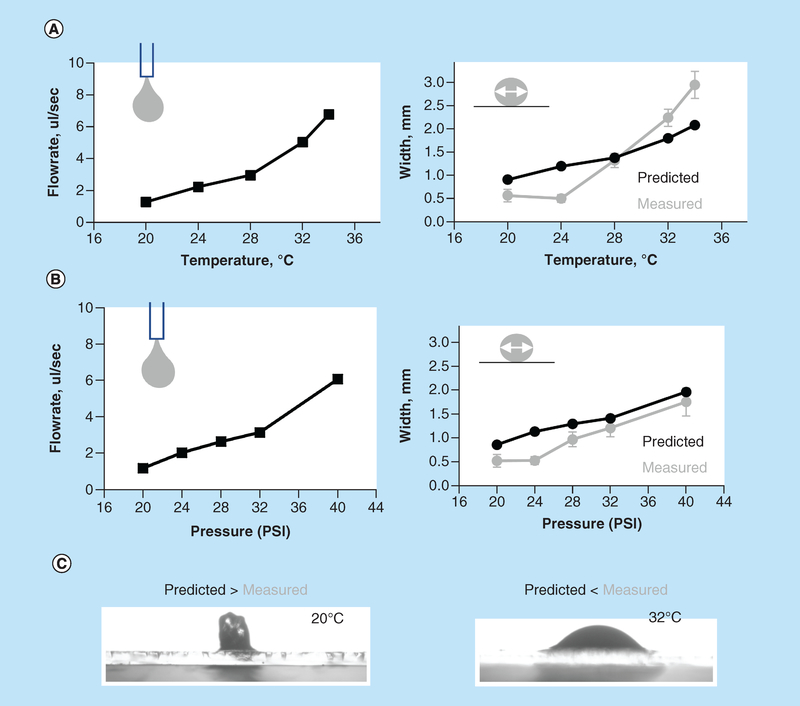

Figure 2. Effects of extrusion pressure and temperature on width of printed gelatin methacryloyl struts.

(A) Predicted versus measured width of GelMA struts. Left panel: the flowrate of 15% GelMA printed using 23-gauge needle at specified temperatures was determined based on the weight of extruded hydrogel. Right panel: thickness of printed lines was then measured experimentally (grey symbols) and compared with the predicted thickness of cylindrically shaped struts (black symbols) based on flowrate values shown in A. Temperature above 28°C led to a wider than predicted struts, while temperature below led to a more narrow ones. (B) Similar measurements done at a constant temperature of 20°C while altering extruder pressure values. (C) Illustrative cross-sections of struts printed at 20° and 32°C are shown.

GelMA: Gelatin methacryloyl.