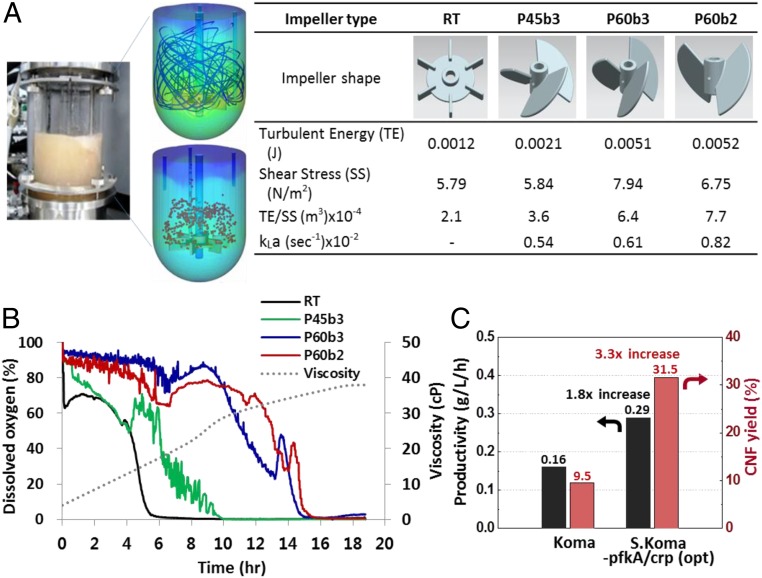

Fig. 2.

CFD for optimizing the fermentation process. (A) Three-dimensional fluid models for turbulent energy and sheer stress using various impeller types: RT (Rushton type), P45b3 (pitch type, 45°, blade #3), P60b3 (pitch type, 60°, blade #3), P60b2 (pitch type, 60°, blade #2) at 10 cP, 250 rpm. kLa (volumetric oxygen transfer coefficient) = ln(∆DO)/(∆t) (DO, dissolved oxygen) at 40 cP, 250 rpm. The pitch-type impellers showed much higher turbulent energy with higher shear stress than those in the Rushton-type impeller. The P60b2 impeller showed highest TE/SS and kLa. (B) Dissolved oxygen vs. time; increasing the dissolved oxygen by optimizing the impeller configuration. The viscosity gradually increases over time, and in the case of RT, DO decreased rapidly after 6 h. The pitch-type impeller with 2 blades (P60b2) exhibited the highest dissolved oxygen amount as a function of time. (C) Plot demonstrating the improved CNF productivity and yield of the optimized strain, S.Koma-pfkA/crp (opt). The optimized S.Koma-pfkA/crp showed much higher CNF productivity (0.29 gCNF/L/h), which is 1.8 times higher, and CNF yield (31.5%), which is 3.3 times higher than wild-type Koma strain.