Table 1.

Optimization of reaction conditionsa

| |||

|---|---|---|---|

| Entry | Base | Temp. (°C) | Yieldb (%) |

| 1c,d | 2-Chloropyridine | −10 | 36 |

| 2d | 2-Chloropyridine | −10 | 56 |

| 3 | 2-Chloropyridine | −10 | 61 |

| 4 | 2-Fluoropyridine | −10 | 45 |

| 5 | Pentafluoropyridine | −10 | 38 |

| 6 | 2-Methoxypyridine | −10 | 0 |

| 7 | Pyridine | −10 | 21 |

| 8 | None | −10 | 34 |

| 9 | 2-Chloropyridine | −41 | 84 |

| 10 | 2-Chloropyridine | −78 | 70 |

| 11e | 2-Chloropyridine | −41 | 64 |

| 12f | 2-Chloropyridine | −41 | 85 |

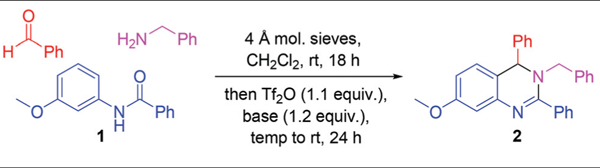

Conditions: 1 (1.0 mmol), benzylamine (1.1 mmol), benzaldehyde(1.1 mmol), 4 Å mol sieves (1.0 g), CH2Cl2 (10.0 mL), rt, 18 h; then base (1.2 mmol), Tf2O (1.1 mmol), temperature; then rt, 24 h.

Isolated yield.

4 Å mol sieves were not added.

N-Benzylidenebenzylamine (1.1 mmol) was used instead of benzylamine and benzaldehyde.

Reflux during final step.

48 h for final step.