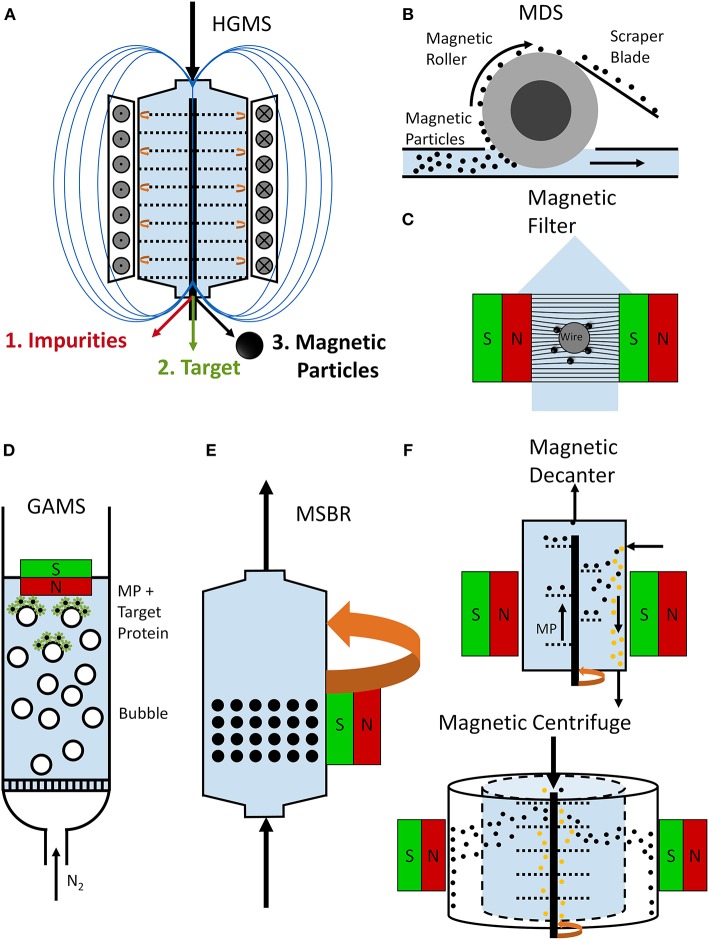

Figure 2.

Schemes of magnetic separator designs. A rotor-stator high-gradient magnetic separator (A) can be used for the purification of target proteins. Here, an electro magnet is used to establish high magnetic field gradients between holey plates (rotor and stator plates). In a first step, the target material is adsorbed to the magnetic particles and separated magnetically from the impurities in the separation chamber. In a second step, the magnetic particles are separated from the target protein, which is eluted (Fraga García et al., 2015; Schwaminger et al., 2019a). An open-gradient magnetic separator (OGMS) (B) in a form of a magnetic drum separator (MDS) is illustrated. Magnetic beads are separated from impurities with a magnetic drum and recovered with a scraper blade (Dong et al., 2015). In a magnetic filtration set-up (C), magnetizable wires, meshes, or bundles are placed in a magnetic field. Magnetic particles bind to these magnetizable matrices leading to a magnetizable filter cake, which improves the magnetic filter performance (Schwaminger et al., 2019b). During a gas-assisted magnetic separation (GAMS) process (D), a gas is bubbled through the reactor leading to the flotation of magnetic particles and attached target molecules, which can be collected with a magnet (Li et al., 2013). A magnetically-stabilized moving bed reactor (MSBR) is based on a rotating magnetic field around the reactor, which allows a fluidization of magnetic beads while they behave like a fixed bed in flow direction (E) (Zong et al., 2013). A magnetic decanter (F) allows the continuous transport of magnetic particles with the magnetized screw while impurities are not affected by the magnetic field and thus separated from the magnetic material (Lindner and Nirschl, 2014). A magnetic centrifuge (G) allows a fast separation due to the density difference and the magnetization of magnetic particles (Lindner and Nirschl, 2014).