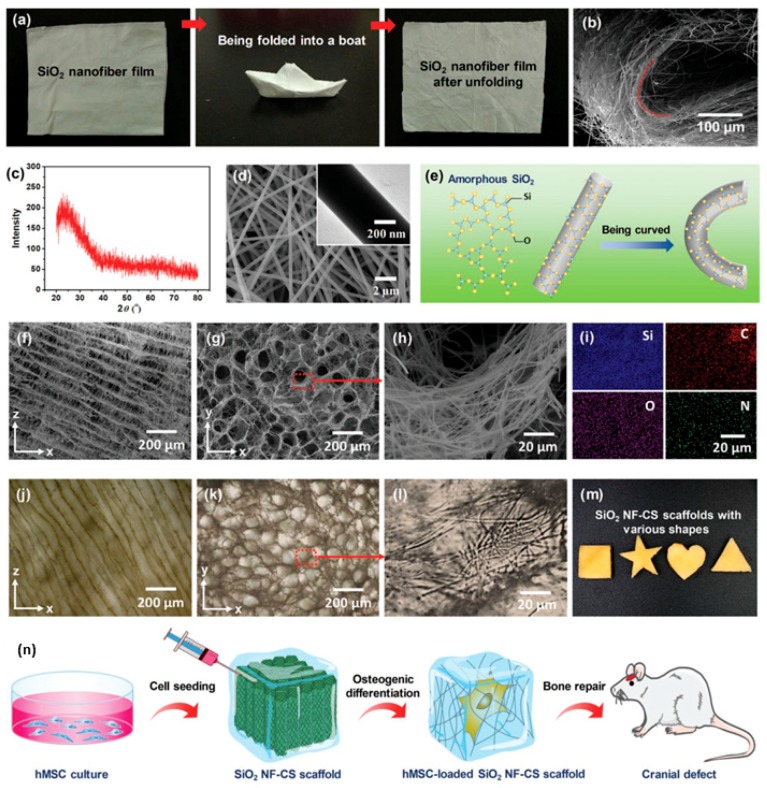

Figure 7.

Construction of 3D nanofbrous scaffolds from flexible inorganic nanofbers. (a) Flexible SiO2 nanofbers with foldability. (b) SEM image of a curved SiO2 nanofbrous mat showing that SiO2 nanofbers could achieve 180° deflection without fracture. (c) X-ray diffractometer spectrum indicating amorphous state of SiO2 nanofbers. (d) SEM image of SiO2 nanofbers showing flawless surface. (e) Schematic of molecular motion when SiO2 nanofbers curved. (f) Longitudinal-section and (g) cross-section SEM images showing SiO2 NF-CS scaffolds possessed honeycomb-like structure. (h) SEM image of pore wall consisting nanofber networks to imitate native ECM. (i) Elemental maps suggesting that chitosan homogeneously covered on SiO2 nanofbers. (j–l) Optical microscope images of hydrated SiO2 NF-CS scaffold showing maintained cellular architecture and nanofbrous networks in aqueous medium. (m) Photograph of SiO2 NF-CS scaffolds with various shapes. (n) Culture of hMSC in SiO2 NF-CS scaffolds [80]. In the field of tissue engineering, cartilage occupies a very special position. Due to the lack of blood supply, the ability of cartilage to recruit cells when it receives damage is far weaker than other tissues in the body [81]. Therefore, the construction of cartilage substitute materials with certain mechanical strength, biocompatibility, and cell adhesion is of great significance for clinical cartilage repair.