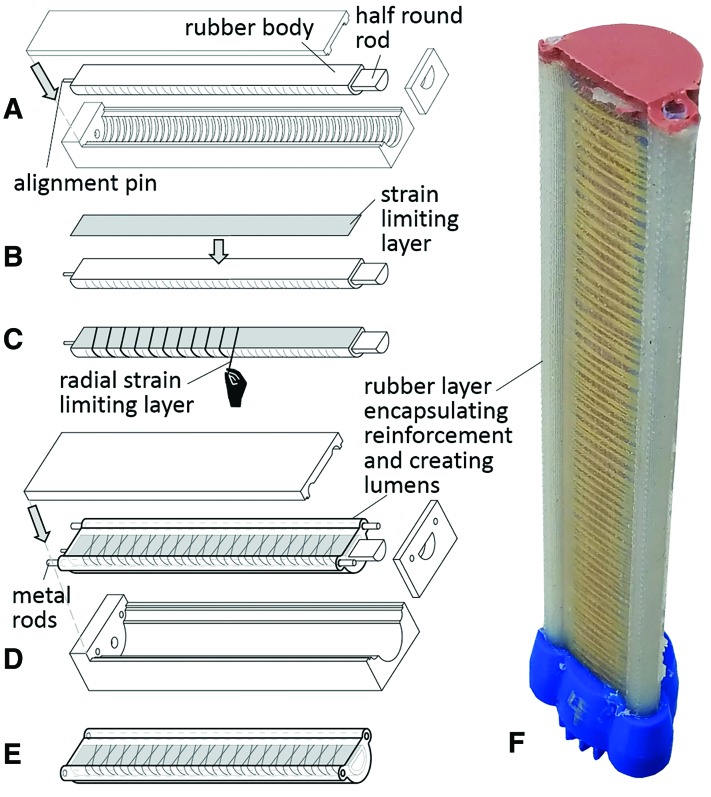

FIG. 2.

Schematic diagram highlighting the fabrication process for a soft fiber-reinforced bending actuator with integrated lumens. (A) The first molding step using a 3D printed three-part mold to define the exterior shape of the rubber body around a half-round steel rod. (B) The strain limiting layer (woven fiberglass) is attached to the flat face of the actuator. (C) Fiber reinforcements (Kevlar fiber) are wound along the entire length of the actuator. (D) The second molding step, the entire actuator is encapsulated in a 2.0 mm thick layer of silicone to anchor all fiber reinforcements and to create lumens with the 3.175 mm diameter steel rods that run parallel to the long axis of the half round rod. (E) All the steel rods are removed and both ends of the actuator are capped with a connection point on one end for pressurized fluid. (F) Fabricated soft actuator measuring 16 cm in length. 3D, three-dimensional. Color images are available online.