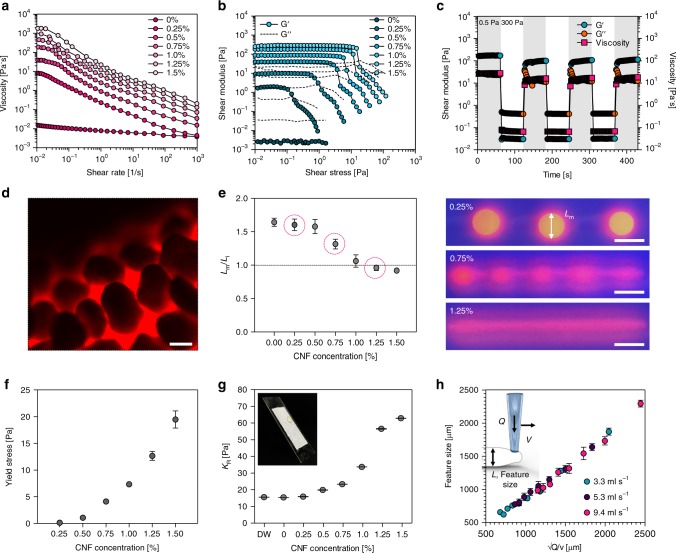

Fig. 2.

Rheological characterization of CNF hydrogel ink containing bacteria and the control of printability. a Viscosity of inks at different contents of CNF as a function of the shear rate. b Storage and loss moduli of inks at different contents of CNF in stress sweeps. c Cyclic stress time sweep for 1 wt% CNF hydrogel ink. For cyclic stress, the shaded regions were at a low stress of 0.5 Pa and unshaded regions were at a high stress of 300 Pa. d Fluorescent microscope image of PTFE particles bound at the surface of the printed CNF hydrogel structure. e Ratio between Lm (measured diameter of printed CNF hydrogels) and Li (intended diameter of printed CNF hydrogels) at different CNF contents. Ink with high printing stability showed a ratio close to 1. f Change of yield stress according to CNF content. g The change of interfacial adhesion stress at the surface of PTFE microparticles facing CNF hydrogel according to CNF content. h The feature size of printed objects could be controlled by the tangential velocity of the needle (v) and the flow rate of the ink through the needle (Q). The printed feature size showed a linear increase following an ideal behavior across a wide range of velocities and flow rates at 1.25 wt% CNF content. Scale bars are 100 μm in d and 5 mm in e. Data are presented as mean ± s.d. (n = 3 in e, f, and g, n = 9 in h)