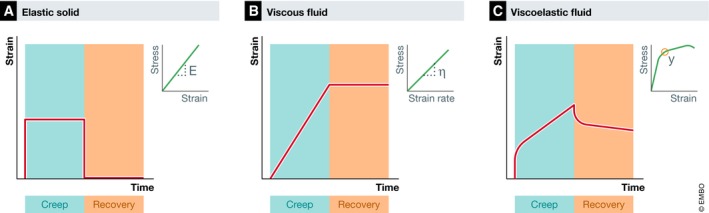

Strain (ε)—time, stress (σ)—strain (ε) and stress (σ)—strain rate (ε%) plots of the material response upon application (creep, green shaded box) and release (recovery, orange shaded box) of mechanical force (A–C).

An elastic solid material displays proportionality between stress and strain. It deforms immediately upon stress application and returns to the initial shape once the force is removed. From the stress–strain plot, the elastic modulus (E) can be calculated as: σ = Eε.

A viscous fluid material displays proportionality between stress and strain rate. It deforms gradually upon stress application and its strain increases over time irreversibly. Once the force is removed, due to energy dissipation, the acquired new shape is retained. From the stress–strain rate plot, viscosity (η) can be calculated as: σ = ηε%.

A viscoelastic material displays at short timescale an immediate elastic deformation, which is followed by a viscous flow at long timescales during mechanical force application. When force is removed, some deformation is quickly recovered due to the elastic nature of the material and the rest of the deformation then gradually decreases either partially (viscoelastic fluid) or completely (viscoelastic solid). From the stress–strain plot, the yield stress (y) can be identified at the point where the elastic deformation stops and the viscous deformations begins (circle).

Abbreviations: ε, strain; σ, stress; E, elastic modulus; ε%, strain rate; η, viscosity; y, yield stress.