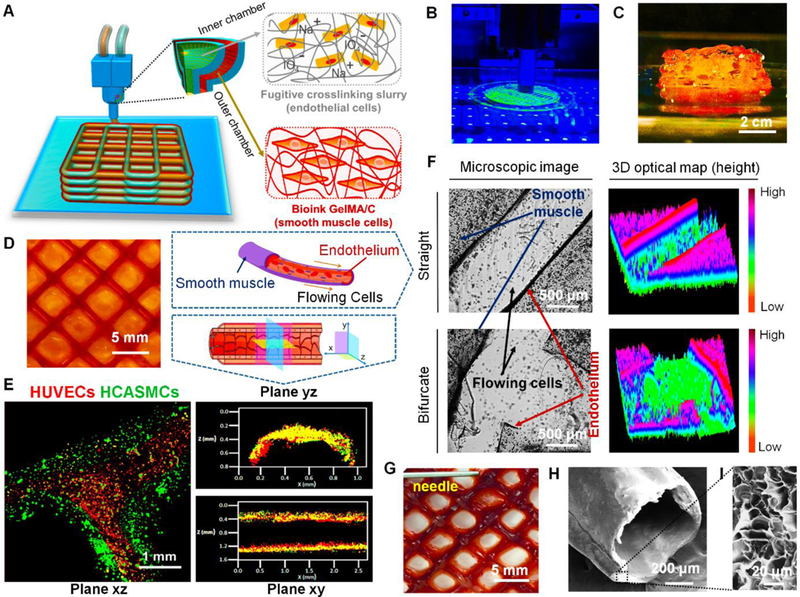

Fig. 2. 3D bioprinting of vasculature construct.

(A), an illustration of basic patterning of 3D vascular architecture fabricated by a coaxial extrusion bioprinter system. The “core-shell” filament consists of two parts: (i) the inner chamber contains fugitive crosslinking slurry and endothelial cells, (ii) the outer chamber contains GelMA/C bioink and smooth muscle cells. (B), a photo image of 3D bioprinting of vasculature on the self-made bioprinter. (C), the side-view image of the 3D bioprinted self-standing vascular construct with 2 cm height. (D), the top-view image of 3D bioprinted vasculature with hollow and interconnected structure (2 layers) after 24 hours of perfusion culture. (E), structural illustration and fluorescence images of 3D bioprinted cell-laden vasculature in three different planes. Endothelial cells were colored red, while smooth muscle cells were colored green. (F), microscopic images and their 3D optical maps (height) of 3D bioprinted vasculature (blood vessel) in straight and bifurcated regions, including smooth muscle layer and endothelium. Flowing cells were observed in the hollow channel after cell perfusion. (G), a photo image of blood plasma perfusion mimicked through a dye injection experiment. (H), cross-sectional morphology of 3D bioprinted vasculature taken by SEM. (I), enlarged morphology of the cross-sectional surface of 3D bioprinted vasculature taken by SEM.