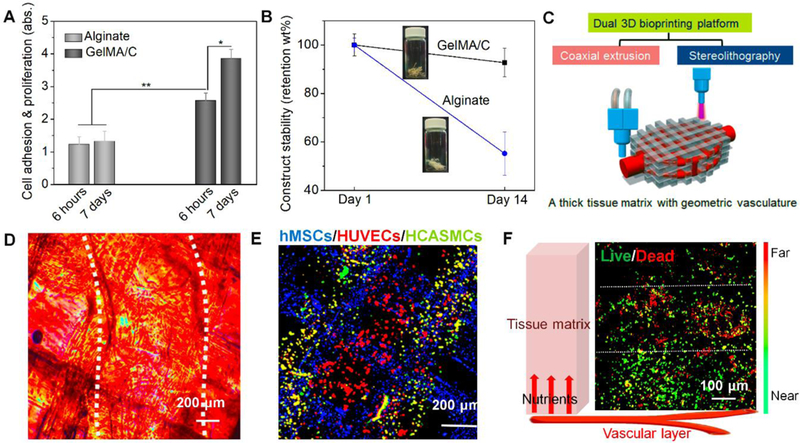

Fig. 3. 3D bioprinting of alginate-based vasculature and 3D bioprinting of tissue matrix with the vasculature.

(A), cell adhesion and proliferation of vascular constructs fabricated by GelMA/C and traditional alginate; the mean ± sd., n≥9, *P <0.05, **P <0.01. (B), structural stability of vascular constructs fabricated by GelMA/C and traditional alginate. (C), schematics of a dual 3D bioprinting platform (coaxial extrusion and stereolithography) to be applied to generate thick, vasculature embedded tissue matrix, where the vascularized tissue is fabricated with vasculature in a “sandwich” manner. (D), microscopic images and (E), a fluorescence image of a 3D bioprinted cellularized tissue matrix. The white dotted lines in D indicate the position of 3D printed vasculature. Dual-layered vasculature (smooth muscle, green; endothelium, red) was embedded into an MSC-laden tissue matrix (grid, blue). (F), nutrient supplementation assay of encapsulated MSCs in the vascularized tissue using Live-Dead staining. Near/Far dedicates the distance away from the vasculature in the schematic. White dotted lines sperate into three zones, i.e., death zone without enough nutrients, transitional zone, and survival zone with enough nutrients. It showed an effective supplementation of nutrients for cell viability related to diffusion.