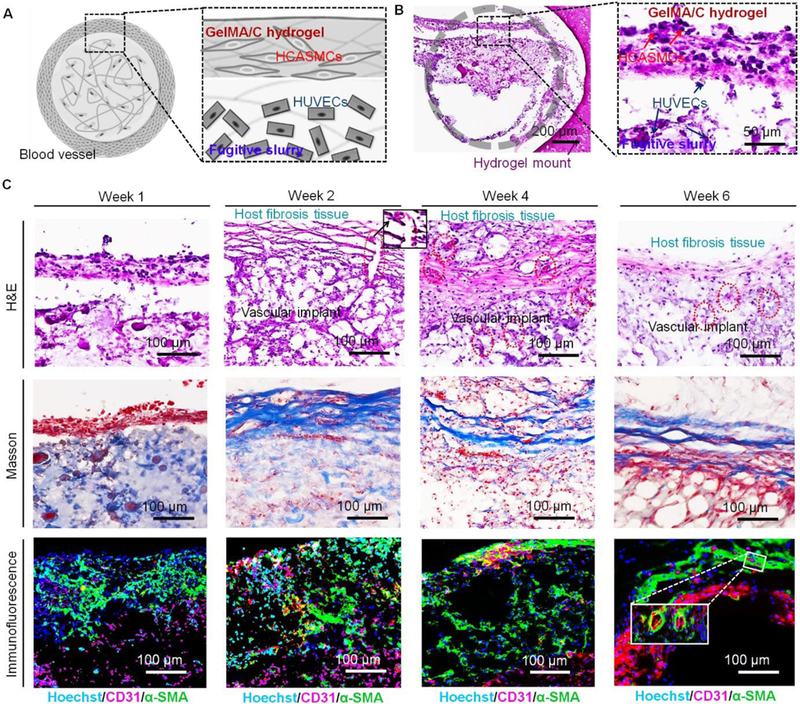

Fig. 6. In vivo development of 3D bioprinted vasculature in NSG immunodeficient mice.

(A), cross-sectional schematics of a single-vessel that was cut from the bioprinted vasculature construct, including HCASMC-laden GelMA/C hydrogel (shell) and HUVEC-laden fugitive slurry (core). (B), H&E stained sections of the cell-laden vasculature with 1x and 20x cross-sectional view harvested at week 1. Gray circle indicates a round vessel lumen encircled by GelMA hydrogel mount. A distinct interface was observed between HCASMC-laden GelMA/C hydrogel and HUVEC-laden fugitive slurry. Some HUVECs adhered to the surface of GelMA/C hydrogel. (C), H&E, Masson, and immunofluorescence (Hoechst, blue; CD31, red; α-SMA, green) stained images of the implanted vasculature construct with 10x cross-sectional view at week 1, 2, 4, and 6. After 2 weeks of implantation, the vasculature was surrounded by the activated host fibroblasts. Vessels (red circles) containing erythrocytes connected the host cell layer with the implants highlighted with an enlarged image (black square). Masson stained images show the host murine fibrosis (or connective tissue, blue fibers) surrounding the 3D bioprinted vasculature. Immunofluorescence images show the structural feature of the vasculature constructs, which is endothelium (red) surrounded by smooth muscle (green). After 6 weeks of implantation, a hollow and mature vessel structure with compact smooth muscle and endothelium was gradually generated. The inset image shows some small vessels generated in the bioprinted vasculature construct.