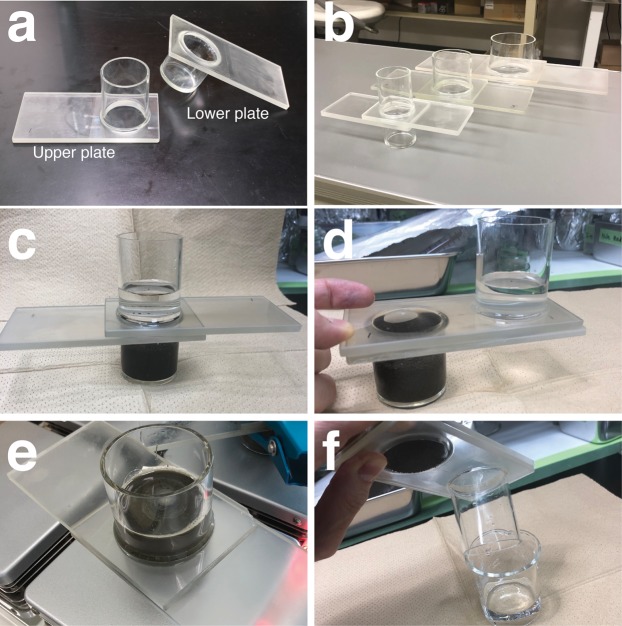

Figure 1. JAMSTEC microplastic-sediment separator (JAMSS) unit.

(A) The upper plate (left) incorporates an open glass tube, while the lower plate (right) incorporates a cylindrical glass container. (B) Small, middle, and large models of assembled JAMSS, consisting of a cylindrical container of 30, 60, and 100 ml volume, respectively. (C) JAMSS during density flotation with sediment in the lower container. (D) Separation of sediment and supernatant by sliding the two plates against each other. (E) JAMSS can be placed on a magnetic stirrer to ensure the sediments are well mixed during microplastic flotation. (F) Microplastics in the supernatant in the upper tube are poured by rinsing the internal walls of the tube.