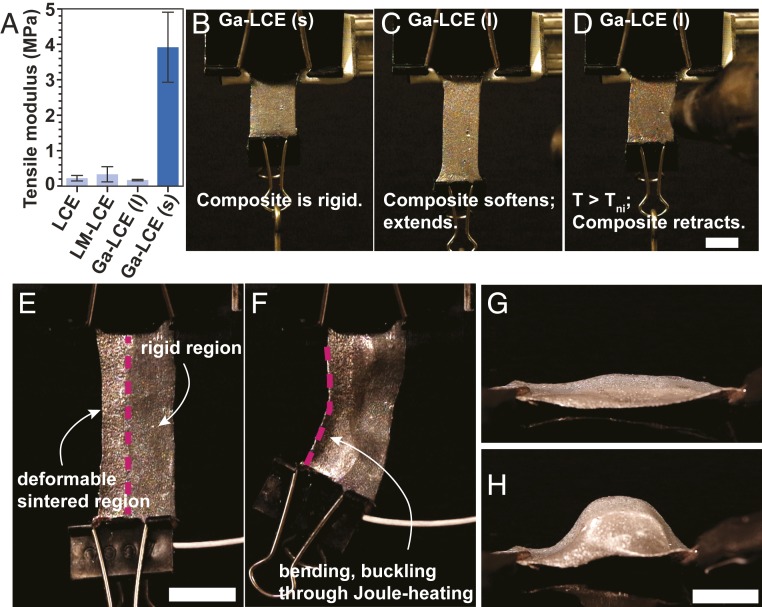

Fig. 5.

Influence of inclusion deformability on composite properties. (A) Tensile moduli for unfilled LCE, 50 vol % LM–LCE, 50 vol % Ga–LCE (l), and 50 vol % Ga–LCE (s) where the (l) and (s) designations refer to the physical state of the gallium microparticles (liquid or solid). Measurements were made at room temperature. Error bars represent SDs for ≥3 measurements. (B) Photograph of Ga–LCE (s) with a hanging weight. The rigid inclusions do not permit extension. (C) Photograph of Ga–LCE (l) with a hanging weight. A heat gun is visible, providing heat to melt the gallium inclusions and permitting the composite to extend. (D) Photograph of Ga–LCE (l) after heating above the nematic-to-isotropic transition temperature (Tni) of the LCE. The composite is able to retract to its original position. (Scale bar, 20 mm.) (E) Photograph of a hanging Ga–LCE composite with specific regions selectively heated to form rigid (solid Ga inclusions) and deformable (liquid Ga inclusions) domains. The deformable domain is mechanically sintered to induce electrical conductivity. (Scale bar, 20 mm.) (F) Photograph of a hanging Ga–LCE bending and buckling during Joule heating due to the rigid domain resisting contraction while the deformable domain contracts. (G) Photograph of a flat Ga–LCE with specific regions selectively heated to form rigid and deformable domains. (H) Photograph of a Ga–LCE bending and buckling during zero-stress actuation induced by Joule heating. (Scale bar, 20 mm.)