Abstract

The transformation of black and red, broken or not, whole rice grains, into breakfast cereals is an interesting way to add value to these snacks for some reasons. Firstly, broken kernels hardly achieve a high market value; whole rice is healthy not only for their nutrient contents but also for their phytochemical profile, rich in phenolic compounds; breakfast cereals from pigmented rice are colored by themselves, and any additional colorant is unneeded; finally, rice is naturally gluten-free and suitable for those with conditions like celiac disease or gluten sensitivity. The objective of this study was to optimize some extrusion parameters that account for the physicochemical properties of extrudates by using response surface methodology. Feed moisture between 15 and 21% and the 4th barrel zone temperature between 110 and 160 °C were the independent variables. Specific features such as color, texture, water solubility and absorption, cold viscosity, expansion, specific volume, and compression force were evaluated. The trials have shown that moisture had a higher impact on the extrusion process than temperature. Less expanded, denser, harder, and darker products were obtained at higher moisture levels. The optimum points were defined at 15.5% and 16.0% of feed moisture and 159 °C and 150 °C of temperature for black and red rice extrudates, respectively. These conditions resulted in cereal breakfast balls with optimal water solubility, volume, texture, and good color. Additionally, cold viscosities and a low compression led to products with a potential high approval by consumers.

Keywords: Pigmented rice flour, RSM, Quality parameters, Extrusion optimization, Snacks

Introduction

Extrusion cooking is classified as a high temperature/short time processing technique that affects the microstructure, the chemical characteristics, the shape, and the texture of the food material (Xu et al. 2016). The thermomechanical actions during extrusion bring about the gelatinization of starch, denaturation of proteins, and the inactivation of enzymes, microbes and several anti-nutritional factors (Chalermchaiwat et al. 2015). This particular technology has been used for the production of ready-to-eat products, such as snacks and breakfast cereals, because of its practicality and the convenience that is offered to consumers (Leyva-Corral et al. 2016).

One of the challenges for the food industry during the extrusion process is to produce healthy products, by using whole grain flour that is rich in fiber, and to overcome negative impacts on the quality characteristics, like high hardness, low expansion and an undesirable color (Oliveira et al. 2017). Therefore, any investigation regarding the effects on the parameters that are involved in this process, such as moisture and temperature, are extremely relevant, in order to produce a breakfast cereal with acceptable characteristics.

Another point to consider is that typical gluten-free products are made with non-wheat flours, such as maize, rice, and sorghum. These raw materials are gaining interest, not only for increasing the nutritional value of the products, but also for contributing to the functional components, such as the phytochemicals (Rocchetti et al. 2017). The demand for gluten-free foods is on the rise and the development of a new gluten-free breakfast cereal will be a valuable option as a ready-to-eat product, being especially suited and available for celiac patients.

Among the healthy gluten-free raw materials, whole grain both black and red rice flours (Oryza sativa L.) present higher amounts of protein, fiber, and phytochemicals, in comparison to white rice flour (Massaretto et al. 2011; Mira et al. 2009; Shen et al. 2009). These phytochemicals, especially the phenolic compounds, are responsible for the typical black and red color of the grains. Typical compounds accumulated in the bran layers are anthocyanins in black rice and proanthocyanidins in red rice (Shao et al. 2018). Furthermore, these phenolic compounds showing a high antioxidant capacity have been related to reduce the risks of developing diabetes, some cancers and cardiovascular diseases (Leardkamolkarn et al. 2011; Tanaka et al. 2011). Therefore, the use of these pigmented varieties of rice is a great alternative in obtaining a healthy and pigmented breakfast cereal, which does not need any additional colorants.

This study aimed to produce extruded breakfast cereals 100% based on whole black and red milled rice grains. A central composite rotatable design (CCRD) was adopted to predict responses as a function of the temperature and the feed moisture within a chosen range. In order to describe the effects of the independent variables on the quality of the extruded products, response surface methodology (RSM) was applied for the generation of the regression models and the contour plots.

Materials and methods

Grain samples and sample preparation

Black rice (Oryza sativa var. SCS 120 Ônix) and red rice samples (Oryza sativa var. SCS 119 Rubi) (Wickert et al. 2014) were provided by Epagri (Itajaí Experimental Station, Santa Catarina, Brazil). Approximately 100 kg of each variety of pigmented rice, sometimes broken grains, were stored under refrigeration (4 °C ± 2 °C) in plastic bottles and light protected and then milled in an analytical mill (Analytical Mill A10, Kinematica GAC, Luzern, Switzerland) before use. The prepared rice flour (≥ 60 mesh to ≤ 250 µm) was conditioned with water for 5 min in a kitchen mixer 24 h prior to extrusion. The exact amount of water added to the rice flour to obtain the desired final feed moisture contents, established according to the experimental design, was calculated by the following equation:

where Mi was the original moisture in g/100 g; Mf was the desired final feed moisture content in g/100 g, and SW was the sample weight in g.

Particle size

The flour particle size was determined in a Produtest Apparatus, Model 4452 (São Paulo, Brazil) (AOAC 2000, method 965.22). A screen set sequence of six sieves as follows: 14 (1.4 mm), 20 (0.840 mm), 35 (0.500 mm), 60 (0.250 mm), 80 (0.177 mm) and 100 (0.150 mm) mesh was used. Three repetitions of each pigmented rice flour were conducted.

Extrusion cooking

The extrusion was performed in a ZKS 30 Werner and Pfleiderer co-rotating twin-screw extruder (Ramsey, USA). Results from preliminary trials were used to select suitable extruder operating conditions. The configuration screw (from the feed extremity to the die) closely followed the parameters and combinations described by Oliveira et al. (2017), with a length to diameter (L/D) ratio of 29:1.

The extrusion was carried out with a 1st, 2nd and 3rd barrel zone temperature of 75, 100 and 125 °C, respectively. The feed rate (15 kg/h) and the screw speed (250 rpm) were kept constant. After the extrusion, the material was dried in a forced-air tunnel until a content ≤ 7% of moisture was achieved.

The experimental design consisted of 12 runs for each rice (black and red) in triplicate, following a 22 CCRD, with feed moistures (15–21%) and the 4th barrel zone temperatures (110–160 °C), as independent variables. For each rice sample, one CCRD was performed. The experimental design with the coded levels and the real values of the independent variables are presented in Table 1. The real levels were selected according to the preliminary tests for suitable extrusion cooking.

Table 1.

Central composite rotatable design and the technological properties of the black rice (a) and the red rice (b) extrudates

| Run | Coded level | Actual value | Technological properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| x1 | x2 | Feed moisture (g/100 g) | Temperature (°C) | SME (KW/kg)a | WSI (%)b | WAI (g/g)c | Cold viscosity (cP) | Expansion Index | Specific volume (mL/g) | Compression force (N) | |

| (a) | |||||||||||

| 1 | − 1 | − 1 | 15.9 | 117 | 70.67 ± 0.84 | 3.46 ± 0.13 | 6.22 ± 0.10 | 60.00 ± 1.00 | 2.56 ± 0.06 | 3.63 ± 0.16 | 32.62 ± 4.14 |

| 2 | 1 | − 1 | 20.1 | 117 | 50.13 ± 0.65 | 2.48 ± 0.10 | 6.24 ± 0.05 | 36.00 ± 2.00 | 1.99 ± 0.08 | 0.85 ± 0.04 | 90.95 ± 8.58 |

| 3 | − 1 | 1 | 15.9 | 153 | 64.27 ± 1.00 | 4.26 ± 0.15 | 5.47 ± 0.23 | 74.00 ± 2.00 | 3.02 ± 0.08 | 3.81 ± 0.24 | 28.23 ± 2.31 |

| 4 | 1 | 1 | 20.1 | 153 | 44.27 ± 1.00 | 2.40 ± 0.16 | 6.61 ± 0.15 | 48.00 ± 1.00 | 1.97 ± 0.07 | 1.79 ± 0.08 | 106.30 ± 6.33 |

| 5 | − 1.41 | 0 | 15.0 | 135 | 66.67 ± 0.84 | 4.61 ± 0.23 | 5.47 ± 0.38 | 81.00 ± 2.00 | 2.87 ± 0.14 | 4.32 ± 0.04 | 21.58 ± 2.67 |

| 6 | 1.41 | 0 | 21.0 | 135 | 42.13 ± 0.65 | 2.66 ± 0.16 | 6.32 ± 0.07 | 42.00 ± 1.00 | 2.09 ± 0.09 | 1.81 ± 0.12 | 131.80 ± 12.31 |

| 7 | 0 | − 1.41 | 18.0 | 110 | 62.67 ± 0.84 | 2.76 ± 0.17 | 6.40 ± 0.05 | 49.00 ± 1.00 | 2.22 ± 0.07 | 2.57 ± 0.08 | 58.72 ± 5.34 |

| 8 | 0 | 1.41 | 18.0 | 160 | 55.47 ± 1.36 | 2.77 ± 0.06 | 6.32 ± 0.05 | 51.00 ± 1.00 | 2.48 ± 0.08 | 3.25 ± 0.31 | 42.24 ± 2.94 |

| 9 | 0 | 0 | 18.0 | 135 | 50.67 ± 0.84 | 2.86 ± 0.04 | 6.25 ± 0.10 | 50.00 ± 0.01 | 2.39 ± 0.10 | 2.38 ± 0.24 | 68.04 ± 6.48 |

| 10 | 0 | 0 | 18.0 | 135 | 50.40 ± 1.00 | 2.76 ± 0.10 | 6.23 ± 0.08 | 54.00 ± 1.00 | 2.34 ± 0.02 | 2.75 ± 0.20 | 67.56 ± 3.61 |

| 11 | 0 | 0 | 18.0 | 135 | 50.93 ± 1.00 | 2.73 ± 0.19 | 6.26 ± 0.08 | 51.00 ± 2.00 | 2.35 ± 0.04 | 2.59 ± 0.21 | 67.65 ± 5.30 |

| 12 | 0 | 0 | 18.0 | 135 | 50.13 ± 1.36 | 2.66 ± 0.10 | 6.27 ± 0.10 | 54.00 ± 0.01 | 2.38 ± 0.05 | 2.91 ± 0.08 | 68.59 ± 2.13 |

| (b) | |||||||||||

| 1 | − 1 | − 1 | 15.9 | 117 | 64.00 ± 0.84 | 8.47 ± 0.30 | 6.82 ± 0.21 | 197.00 ± 12.00 | 3.01 ± 0.10 | 2.52 ± 0.04 | 21.18 ± 2.64 |

| 2 | 1 | − 1 | 20.1 | 117 | 50.67 ± 0.84 | 3.31 ± 0.04 | 7.58 ± 0.14 | 86.00 ± 2.00 | 2.24 ± 0.05 | 1.80 ± 0.16 | 82.80 ± 9.66 |

| 3 | − 1 | 1 | 15.9 | 153 | 62.13 ± 1.36 | 8.63 ± 0.21 | 6.70 ± 0.21 | 228.00 ± 12.00 | 3.20 ± 0.04 | 5.91 ± 0.09 | 16.44 ± 2.32 |

| 4 | 1 | 1 | 20.1 | 153 | 52.80 ± 1.36 | 3.74 ± 0.02 | 7.53 ± 0.06 | 111.00 ± 3.00 | 2.21 ± 0.08 | 1.01 ± 0.14 | 73.79 ± 4.88 |

| 5 | − 1.41 | 0 | 15.0 | 135 | 75.47 ± 1.07 | 10.94 ± 0.09 | 6.91 ± 0.06 | 271.00 ± 4.00 | 3.30 ± 0.04 | 4.55 ± 0.17 | 20.84 ± 2.11 |

| 6 | 1.41 | 0 | 21.0 | 135 | 43.47 ± 0.65 | 2.48 ± 0.04 | 7.74 ± 0.10 | 111.00 ± 6.00 | 2.25 ± 0.04 | 1.87 ± 0.10 | 82.55 ± 11.80 |

| 7 | 0 | − 1.41 | 18.0 | 110 | 65.33 ± 0.84 | 5.87 ± 0.16 | 7.18 ± 0.09 | 114.00 ± 5.00 | 2.49 ± 0.03 | 1.93 ± 0.08 | 37.18 ± 4.23 |

| 8 | 0 | 1.41 | 18.0 | 160 | 67.47 ± 1.36 | 7.92 ± 0.02 | 7.77 ± 0.05 | 177.00 ± 10.00 | 2.54 ± 0.03 | 2.68 ± 0.15 | 19.99 ± 2.67 |

| 9 | 0 | 0 | 18.0 | 135 | 58.67 ± 0.84 | 7.37 ± 0.13 | 7.39 ± 0.30 | 164.00 ± 11.00 | 2.76 ± 0.08 | 2.38 ± 0.07 | 26.67 ± 2.68 |

| 10 | 0 | 0 | 18.0 | 135 | 58.40 ± 1.00 | 7.33 ± 0.10 | 7.55 ± 0.28 | 163.00 ± 4.00 | 2.78 ± 0.04 | 2.88 ± 0.08 | 26.48 ± 2.58 |

| 11 | 0 | 0 | 18.0 | 135 | 57.33 ± 0.84 | 7.56 ± 0.04 | 7.23 ± 0.04 | 176.00 ± 4.00 | 2.78 ± 0.03 | 2.98 ± 0.22 | 26.39 ± 3.28 |

| 12 | 0 | 0 | 18.0 | 135 | 58.93 ± 1.00 | 7.22 ± 0.29 | 7.33 ± 0.07 | 154.00 ± 7.00 | 2.76 ± 0.07 | 2.83 ± 0.13 | 27.42 ± 2.12 |

| Run | Technological properties | ||

|---|---|---|---|

| L* (lightness) | C* (chroma) | h* (hue angle) | |

| (a) | |||

| 1 | 25.09 ± 0.32 | 2.31 ± 0.03 | 81.82 ± 0.71 |

| 2 | 19.17 ± 0.44 | 2.03 ± 0.02 | 69.01 ± 0.62 |

| 3 | 25.19 ± 0.64 | 2.39 ± 0.05 | 78.91 ± 0.39 |

| 4 | 19.79 ± 0.61 | 2.20 ± 0.03 | 74.64 ± 1.28 |

| 5 | 25.64 ± 0.37 | 2.21 ± 0.01 | 86.47 ± 0.23 |

| 6 | 19.13 ± 0.59 | 2.10 ± 0.07 | 67.98 ± 1.91 |

| 7 | 22.25 ± 0.83 | 2.16 ± 0.04 | 74.74 ± 0.71 |

| 8 | 21.77 ± 0.30 | 2.50 ± 0.02 | 75.35 ± 0.70 |

| 9 | 21.12 ± 0.89 | 2.23 ± 0.04 | 78.53 ± 0.34 |

| 10 | 21.24 ± 1.00 | 2.25 ± 0.02 | 78.51 ± 0.62 |

| 11 | 21.66 ± 0.53 | 2.22 ± 0.03 | 78.37 ± 0.94 |

| 12 | 21.79 ± 0.55 | 2.26 ± 0.01 | 78.29 ± 0.76 |

| (b) | |||

| 1 | 38.29 ± 1.04 | 4.55 ± 0.03 | 40.55 ± 0.65 |

| 2 | 32.69 ± 0.46 | 4.38 ± 0.05 | 41.35 ± 0.43 |

| 3 | 37.60 ± 0.58 | 4.45 ± 0.03 | 40.14 ± 0.44 |

| 4 | 31.68 ± 0.49 | 4.37 ± 0.03 | 42.48 ± 0.92 |

| 5 | 40.53 ± 1.00 | 4.51 ± 0.02 | 40.39 ± 0.62 |

| 6 | 30.43 ± 0.28 | 4.25 ± 0.07 | 43.07 ± 0.80 |

| 7 | 35.08 ± 1.17 | 4.43 ± 0.03 | 41.23 ± 0.54 |

| 8 | 34.46 ± 0.61 | 4.59 ± 0.06 | 40.64 ± 0.39 |

| 9 | 36.11 ± 0.47 | 4.52 ± 0.03 | 40.69 ± 1.10 |

| 10 | 36.45 ± 0.28 | 4.52 ± 0.08 | 41.24 ± 0.41 |

| 11 | 35.96 ± 0.28 | 4.55 ± 0.04 | 40.93 ± 0.67 |

| 12 | 35.98 ± 0.15 | 4.58 ± 0.04 | 40.62 ± 0.14 |

Values are means of at least three replicates and the standard errors of values

aSpecific mechanical energy

bWater Solubility Index

cWater Absorption Index

Specific mechanical energy (SME)

The SME was calculated for each trial by using the actual screw speed (ASS = 250 rpm), the motor power rating (MPR = 4000 kW/h), the motor torque (%), the rated screw speed (RSS = 500 rpm) and the mass flow rate (Q = 15 kg/h) (Oliveira et al. 2017) as shown in the equation:

Water Solubility Index (WSI) and Water Absorption Index (WAI)

The WSI and the WAI of the extrudates were determined based on the methodology proposed by Anderson et al. (1969), by using three samples of each breakfast cereal. An amount of 2.5 g of each sample was suspended in 30 mL of water at 25 °C for 30 min. The suspension was centrifuged at 2.200×g for 10 min and the supernatant was evaporated and dried at 105 °C for 4 h. The WSI and the WAI were calculated by:

where CRM was the centrifugal residual mass in g; SW was the sample weight in g; and ERM was the evaporation residual mass in g.

Cold viscosity (CV)

The pasting properties were determined by a Viscometer Model—Rapid Visco Analyzer (RVA) 4500 (Warriewood, Australia) controlled by Thermocline software (Newport Scientific Pty Ltd., Warriewood, Australia). The CV was evaluated in three samples of each rice extrudate according to the standard method AACC 62-02.01 (AACC 2012).

Expansion Index (EI)

The EI of the extrudates was determined by calculating the average of six samples from each trial. The diameters were measured in two different parts of the breakfast cereal using a Universal Craftsman Caliper (Brennan et al. 2008). The EI was calculated by:

where DC was the average extrudate diameter in mm; and DM was the die diameter in mm.

Specific volume (SV)

The SV of the extrudates was determined in three samples of each extrudate, based on the displacement of the millet from a known mass sample (20 g) in a 1L beaker (Meng et al. 2010). The SV was calculated by:

where v was the excess millet seed volume in mL; and p was the sample weight in g.

Compression force (CF)

The textural quality (the CF or the hardness) of 8 samples of each breakfast cereal was examined for their CF in a TA-XT2iPlus Texture Analyzer (Stable Micro Systems Ltd., Godalming, UK) by using a Warner–Bratzler Probe (HDP/WBV). The peak force (N) of the first compression that was necessary for the rupture of the breakfast cereal sample was considered to be the CF (Yang et al. 2008). The parameters used were: the speed of the pre-test, the test and the post-test of 2.0, 1.0 and 10 mm/s, respectively, with a probe distance of 30 mm and a force threshold of 0.05 N.

Instrumental color

The colors of the extrudates were determined by a Mini Scan XE 45/0-L Spectrophotometer (HunterLab, Reston, USA) and they were based on the CIE L*C*h system (L*C*h color space—cylindrical coordinates). The results were calculated as the average of three readings for each sample. The conditions used were: D65 illuminant and a 10° viewing angle.

Statistical analysis

The data analysis was reported by the RSM in order to investigate the effects of feed moisture and the 4th barrel zone temperatures on the technological properties of the black and red rice extrudates. For the experimental design, 4 factorial runs, 4 axial points (α = 1.41) and 4 replications of the central point, resulting in 12 runs for each pigmented rice were used (Montgomery 1991). For each dependent variable, a second-order polynomial regression model was generated.

All the data were analyzed according to a two-way analysis of variance (Anova) by using the Statistica 7.0 Software Program (Statsoft, Tulsa, USA) and P < 0.10 was considered as statistically significant. A regression coefficient (R2) of 0.80 was adopted in order to guarantee the prediction values from the regression models and the construction of the contour curves.

Results and discussion

The black and red rice flours that were used in the extrusion process showed a uniform particle size distribution, as 90% were between 0.177 and 0.250 mm. The uniformity of the particle size is important, in order to set the degree of water absorption. If particle sizes present a high dispersion, the smaller ones absorb water more quickly and consequently absorb more water during the extrusion process. Therefore, heterogeneous particle sizes would result in different degrees of cooking and decrease the quality of the final products (Martínez et al. 2014).

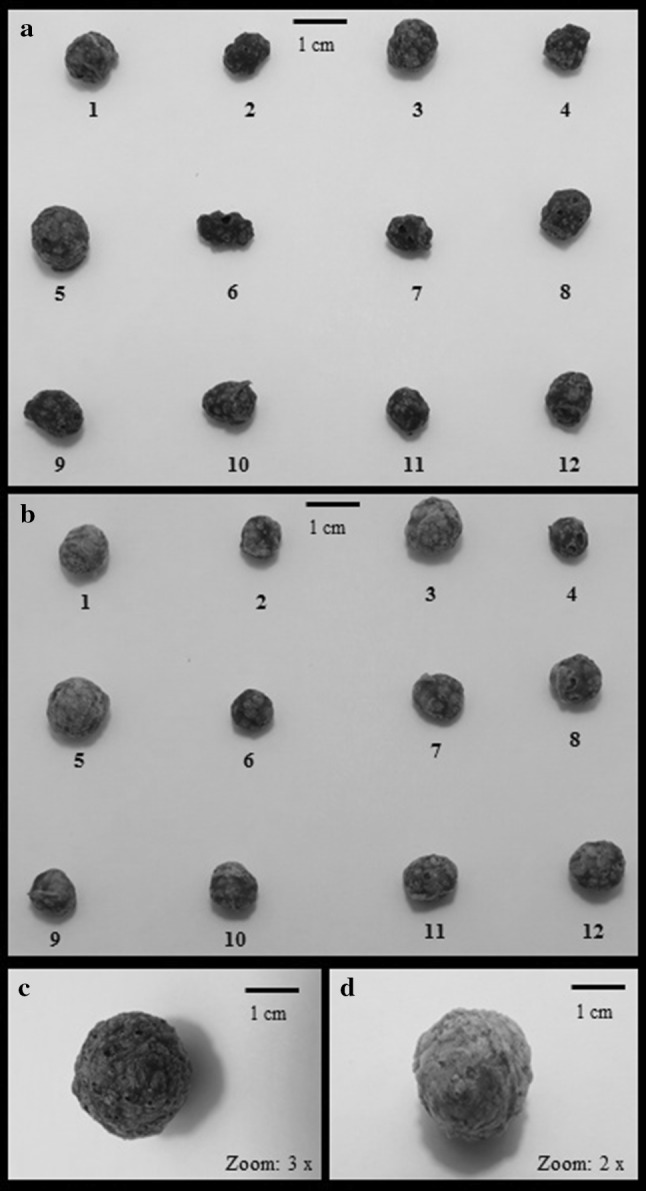

The influence of feed moistures and 4th zone barrel temperatures during extrusion on the technological properties of the black rice extrudates (BRE) and the red rice extrudates (RRE) of the 12 runs are shown in Table 1, a and b, respectively. Images of extrudates obtained in the 12 runs of each pigmented rice and their optimal points can be seen in Fig. 1.

Fig. 1.

Images of the 12 black rice (a), red rice (b) extrudates, and their respective optimal points (c, d). Optimal conditions were 15.5% and 16.0% feed moistures and 159 °C and 150 °C temperatures, respectively, for black and red rice extrudates (color figure online)

Specific mechanical energy (SME)

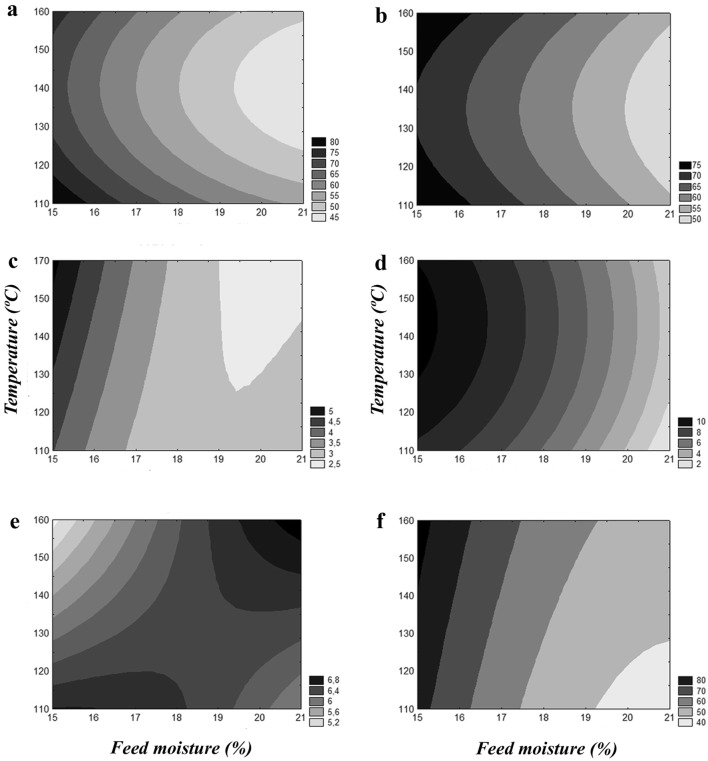

The specific mechanical energy values ranged from approximately 42–70 KW/kg for both types of extruded products. High values of SME positively affect the expansion of breakfast cereals, resulting in a better quality of the extrudate products (Meng et al. 2010). The extrusion processes resulted in a higher SME when working with lower values of feed moisture and with extremely lower or higher points of temperature (Fig. 2a, b). Under these conditions, the shear degree was higher during the extrusion processes, thus increasing the energy involved in the operation. According to Pardhi et al. (2016), higher SME values result in a greater degree of starch granule gelatinization, by promoting the rupture of intermolecular hydrogen bonds. On the opposite, higher feed moistures generate less mechanical energy, due to a lubrication effect; hence, decreasing the SME values (Pardhi et al. 2016).

Fig. 2.

Specific mechanical energy, Water Solubility Index and Water Absorption Index contour curves of the black rice (a, c, e), red rice (b, d) extrudates, and cold viscosity contour curve of the black rice (f) extrudate (color figure online)

The SME regression model for the process variables was statistically significant (P < 0.001) for both of the varieties of the pigmented rice (Table 2) and the regression coefficients (R2) for the BRE and the RRE were 0.9947 and 0.8199, respectively.

Table 2.

The regression models for the process variables and the product properties when using the independent variables of feed moistures (x1) and 4th barrel zone temperatures (x2) of the pigmented rice extrudates

| Response | BRE regression modelsa | R2 | RRE regression modelsb | R2 |

|---|---|---|---|---|

| SME (KW/kg)c | 50.53 − 9.42x1 − 2.81x2 + 2.09x21 + 4.43x22 | 0.9947 | 57.68 − 8.50x1 + 2.82x22 | 0.8199 |

| WSI (%)d | 2.75 − 0.70x1 + 0.09x2 + 0.43x21 − 0.22x1x2 | 0.9834 | 7.37 − 2.75x1 + 0.44x2 − 0.53x21 − 0.43x22 | 0.9643 |

| WAI (g/g)e | 6.30 + 0.21x1 − 0.10x2 − 0.12x21 + 0.36x1x2 | 0.9428 | ns | ns |

| Cold viscosity (cP) | 51.25 − 13.23x1 + 3.63x2 + 4.43x21 | 0.9652 | 164.46 − 56.68x1 + 18.06x2 + 10.16x21 − 12.73x22 | 0.9762 |

| Expansion Index | 2.35 − 0.34x1 + 0.10x2 + 0.05x21 − 0.12x1x2 | 0.9656 | 2.77 − 0.40x1 + 0.03x2 − 0.12x22 − 0.05x1x2 | 0.9918 |

| Specific volume (mL/g) | 2.73 − 1.00x1 + 0.38x21 | 0.8854 | 2.77 − 1.18x1 + 0.46x21 − 1.04x1x2 | 0.9077 |

| Compression force (N) | 67.95 + 36.57x1 + 4.63x21 − 8.54x22 + 4.94x1x2 | 0.9814 | 29.13 + 25.82x1 − 4.76x2 + 14.06x21 | 0.9525 |

| L* (lightness) | 21.45 − 2.57x1 + 0.50x21 + 0.31x22 | 0.9785 | 36.13 − 3.23x1 − 0.32x2 − 0.34x21 − 0.70x22 | 0.9858 |

| C* (chroma) | 2.24 − 0.08x1 + 0.09x2 − 0.05x21 + 0.04x22 | 0.8702 | ns | ns |

| h* (hue angle) | 77.94 − 5.41x1 − 1.54x22 + 2.31x1x2 | 0.9474 | 40.86 + 0.87x1 + 0.38x21 + 0.39x1x2 | 0.9173 |

R2, regression coefficient; ns, the mathematical models were not statistically significant (P ≤ 0.10)

aBRE black rice extrudate

bRRE red rice extrudate

cSME specific mechanical energy

dWSI Water Solubility Index

eWAI Water Absorption Index

Water Solubility Index (WSI), Water Absorption Index (WAI) and cold viscosity (CV)

The main hydration properties of the extrudates were the WSI and the WAI. The WSI reflects the degree of gelatinization, dextrinization, and solubilization of the starch granules, by measuring the amount of the soluble components that were released from the starch after the extrusion. The WSI ranged from 2.40 to 4.61% for the BRE and from 2.48 to 10.94% for the RRE and were dependent on the extrusion conditions used. Increasing temperature and decreasing feed moisture resulted in higher WSI (Fig. 2c, d). The starch granule solubility increased with higher values of temperature and lower values of moisture. These observations are consistent with a previous study (Ding et al. 2005), in which authors reported a maximum degree of gelatinization by using similar extrusion conditions of temperature and feed moisture. This behavior was caused by an intense shear fragmentation of the starch granules during the extrusion process while at lower moisture, resulting in a high WSI and better digestibility of the starch.

The WSI regression model for the process variables was statistically significant (P < 0.001) for both of the pigmented rice extrudates (Table 2) and the regression coefficients (R2) were 0.9834 for the BRE and 0.9643 for the RRE.

The WAI indicates the amount of water that is absorbed by the starch granules pointed to the digestibility and the gelatinization of the starch (Pardhi et al. 2016). The WAI ranged from 5.47 to 6.61 g/g for the BRE and from 6.70 to 7.77 g/g for the RRE. The WAI of the BRE was increased by extremely higher contents of the feed moisture and higher temperature (Fig. 2e). Ding et al. (2005) suggested that moisture is directly related to WAI, since the water content acts as a plasticizer during the extrusion process, thus reducing the degradation of the starch granules and increasing the water absorption indexes.

The WAI regression model for the process variables was statistically significant (P < 0.001) for the BRE (Table 2) and the regression coefficient (R2) was 0.9428. No WAI contour plot was generated for the RRE, because the regression coefficient (R2) that was obtained for this parameter was lower (0.7655) than the minimum of 0.8, which was previously adopted, in order to guarantee the prediction values from the regression models.

Cold viscosity (CV) is an important property of breakfast cereals, as they are usually consumed by immersion in cold milk. This property represents the structural modification of the starch granules. The CV values varied from 36 to 81 cP for the BRE and from 86 to 271 cP for the RRE and these values were influenced by the feed moisture and the temperature. An intermediate CV value is desired for breakfast cereals, since higher CV values may result in a fragile structure of the extrudates and they may disintegrate rapidly after immersion in milk, therefore, resulting in a less crunchy final product. On the other hand, lower CV values may difficult water absorption and generate a not so desirable tougher product.

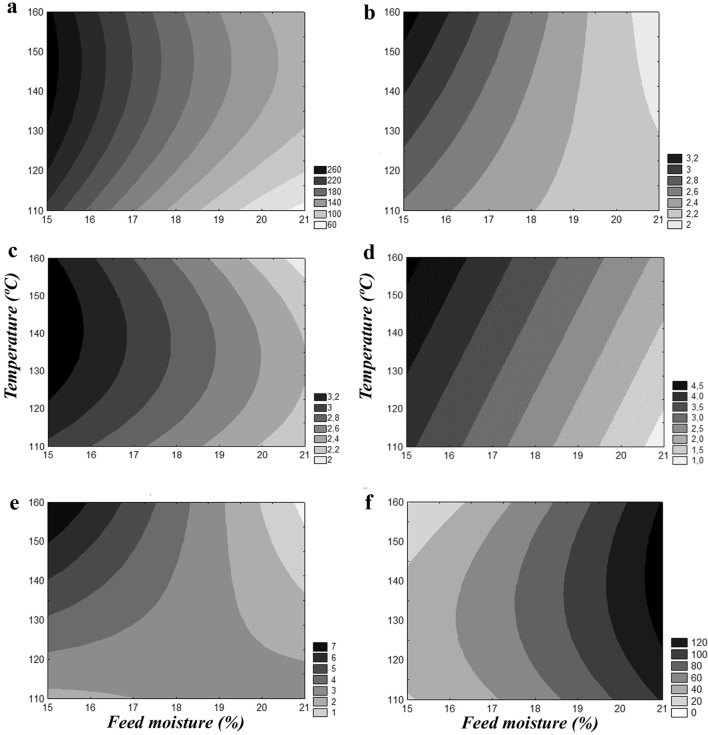

For the BRE and the RRE, the intermediate CV values varied in a range of 16–18% for the feed moistures and in a range of 110–160 °C for the temperatures (Figs. 2f, 3a). The CV regression model for the process variables was statistically significant (P < 0.001) for the BRE and the RRE (Table 2). The regression coefficient (R2) was 0.9652 for the BRE and 0.9762 for the RRE.

Fig. 3.

Cold viscosity contour curve of the red rice (a) extrudate, Expansion Index and specific volume contour curves of the black rice (b, d), red rice (c, e) extrudates, and compression force contour curve of the black rice (f) extrudate (color figure online)

Expansion Index (EI) and specific volume (SV)

The EI and the SV are important parameters for the production of the extruded cereals, as they reflect the degree of puffing. The SV measures the volumetric expansion, considering the radial and the axial expansions when the extrudates leave the die nozzle. The Expansion Index (EI) is based on the perpendicular expansion and is calculated by the ratio between the diameter of the extrudate and the diameter of the matrix (3.85 mm) (Ding et al. 2005; Oliveira et al. 2018). The expansion of the extrudates highly depended on the presence of amylopectin in the starch granules, due to its high molecular ramification.

The EI ranged from 1.97 to 3.02 for the BRE and from 2.21 to 3.30 for the RRE. The expansion of the cereal balls was inversely related to the feed moisture and directly related to temperature. In the present work, the EI of the BRE and the RRE was higher when there was a decrement of the feed moisture and when there was an increment of the temperature (Fig. 3b, c). These observations are consistent with a previous study (Dalbhagat et al. 2019).

The SV ranged from 0.85 to 3.63 mL/g for the BRE and from 1.01 to 5.91 mL/g for the RRE. Similar behavior of the influence of feed moisture and temperature on EI was observed for the SV (Fig. 3d, e). According to Oliveira et al. (2017), samples with a high EI also present a high SV, and for these parameters, feed moisture shows a greater effect on expansion than temperature does. This can be seen in Fig. 1, where it is possible to observe that the extrudates from runs 1, 3 and 5 showed higher expansion rates, due to the low feed moistures, independent of the temperatures that were used in the process. Nevertheless, with higher feed moisture, probably the starch gelatinization was reduced and the gas bubble growth was retarded, resulting in denser and less crunchy final products (runs 2, 4 and 6). González et al. (2013) explain that under high moisture conditions, the expansion occurs when the product leaves the die, but the structure collapses before cooling, resulting in a dense and tough product.

The EI and SV regression models for the process variables were statistically significant (P < 0.001) for both of the pigmented rice extrudates (Table 2). The EI regression coefficients (R2) were 0.9654 for the BRE and 0.9918 for the RRE, and the SV regression coefficients (R2) were 0.8854 for the BRE and 0.9077 for the RRE.

Compression force (CF)

The CF is the average force required for a probe to break the extruded product into small pieces, this force represents the resistance of extrudate to initial penetration and is believed to be the hardness of extrudate (Pardhi et al. 2016; Ding et al. 2005). The CF ranged from 21.58 to 131.80 N for the BRE and from 16.44 to 82.80 N for the RRE. It was predicted by the regression model that the feed moisture has a significant effect on the compression force of both extrudates at all ranges of temperatures. An increase in the feed moisture corresponded to an increase in hardness, as shown in Figs. 3f and 4a. This correlation has already been reported by other authors (Oliveira et al. 2017, 2018; Pardhi et al. 2016; Ding et al. 2005). Water acts as a plasticizer on the starch granules, causing a reduction of the viscosity and reducing the mechanical energy dissipation during the extrusion processes. The result is a dense final product, with a compressed bubble growth and lower crispness (Altan et al. 2008).

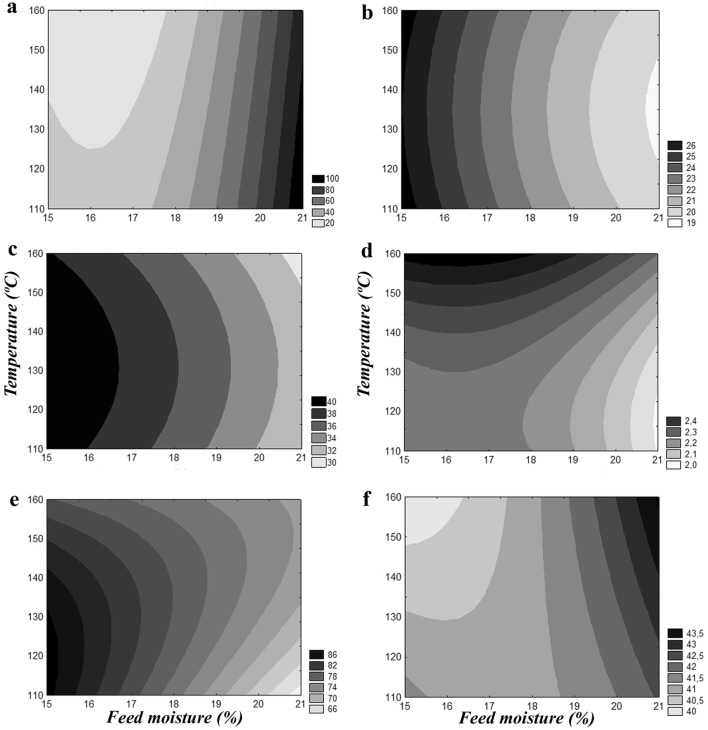

Fig. 4.

Compression force contour curve of the red rice (a), color coordinates L*C*h of the black rice (b, d, e), color coordinates L*h* of the red rice (c, f) extrudates (color figure online)

In the current study, the CF was more affected by the feed moisture than it was by the temperature, independent of the temperature used during extrusion. However, according to Ding et al. (2005), it was expected that higher temperatures would decrease the melt viscosity, which would then facilitate the bubble growth, thus producing a lower density of the extrudates, with small and thin cell structures and, consequently, higher crispness.

The compression force (hardness) and the crispness are sensorial perceptions of the consumer, and they are related not only to the bubble growth of the extruded product but also to the expansion properties (the EI and the SV) (Oliveira et al. 2017). The influence of moisture on the CF supported the results of the EI and the SV on the extrudates (Fig. 3b–e). As there was an increase in the feed moisture, a higher CF was observed in the extrusion processes, resulting in lower values of the EI and the SVon the extrudates; consequently, there was an unacceptable lack of crispness for the consumer.

The CF regression model for the process variables was statistically significant (P < 0.001) for both of the pigmented rice extrudates (Table 2) and the regression coefficients (R2) were 0.9814 for the BRE and 0.9525 for the RRE.

Instrumental color

The pigmented rice varieties presented a characteristic grain color due to the presence of specific phenolic compounds. Anthocyanins in black rice and proanthocyanidins in red rice are the main compounds which give the grains their typical color (Shao et al. 2018). The color characteristics of the BRE and the RRE in all runs can be seen in Fig. 1. The extrusion conditions changed the color of the extrudates. The L* (lightness), the C* (chromaticity) and the h* (hue angle) values of the BRE were affected (P < 0.001, 0.003 and 0.001, respectively) by both, feed moistures and temperatures (Fig. 4b, d, e). In the RRE, the L* and the h* (P < 0.001) (Fig. 4c, f) were also affected by the feed moisture and the temperature, while for the C*, no regression model was validated (Table 2). The L*, C* and h* regression coefficients (R2) were 0.9785, 0.8702 and 0.9474 respectively for the BRE and they were 0.9858 (L*) and 0.9173 (h*) for the RRE.

The L* values were in the range of 19.13–25.64 for the BRE and in the range of 30.43–40.53 for the RRE, while the non-extruded black rice and red rice flours presented L* values of 58.57 and 74.63, respectively, which indicates that the extrusion process changed the color and produced darker products.

The colors of extrudates are a result of the presence of natural pigments in the raw materials, and the darkening may be explained by the non-enzymatic browning reactions, such as Maillard and Caramelization, which occur during the extrusion process. Furthermore, a degradation of the pigments may also take place and contribute to the change of color in the extruded products. As expected, the extrusion conditions affected the degree of darkening (Dalbhagat et al. 2019; Oliveira et al. 2017, 2018). Higher L* values were obtained as a result of lower feed moistures and in the range of temperatures from 110 to 160 °C, for both of the pigmented extrudates (Fig. 4b, c). The chromaticity of the BRE (C*) was higher when an increased temperature and a decreased feed moisture were used (Fig. 4d). The C* value varied between 2.03 and 2.50 for the BRE and was 2.16 for the raw black rice flour. Higher values of angle h* were obtained with lower feed moisture contents and temperatures for the BRE, as opposed to the behavior observed for the RRE (Fig. 4e, f). The h* values were in the range of 67.98–86.47 for the BRE and of 40.14–43.07 for the RRE.

Optimal point definition

The technological properties and the visual aspects of extrudates obtained in the 12 runs of each pigmented rice are shown in Table 1 and Fig. 1, respectively. For the definition of the optimal points, it was necessary to select the dependent variables that best characterized the expanded extruded products. Thus, the contour curve areas, with maximized WSI, EI, and SV values, together with the intermediate WAI and CV values and minimizedCF values, were all analyzed. There was also a preference for obtaining lighter (higher L* value) extruded products (Figs. 2, 3, 4).

The choice of the feed moisture content and the 4th barrel zone temperature was essential for producing a final extruded product with the greatest technological quality. For the BRE, the optimal point was defined as being 15.5% of feed moisture and 159 °C of the 4th barrel zone temperature, with values corresponding to − 1.175 and 1.3536 of the coded levels, respectively. For the RRE, the optimal point was defined as being 16% of feed moisture and 150 °C of the 4th barrel zone temperature, with values corresponding to − 0.94 and 0.846 of the coded levels, respectively.

The regression models were validated by a comparison between the predicted and the experimental values (Table 2). A relative deviation of ≤ 10% had been established to validate the mathematical model. The relative deviation indicated that the mathematical models for the dependent variables of SME, WSI, WAI, CV, EI, SV, CF, and the color parameters were valid for the prediction of the experimental values of the pigmented extrudates, except for the WAI and the C* values of the RRE.

Conclusion

This study has shown that the extrusion cooking can be considered a promising rice processing technology to obtain new types of innovative extruded products such as gluten-free breakfast cereals based on 100% pigmented rice flours. The use of whole black and red rice provided naturally colored products and no addition of any other food colorants are required. The appropriate combinations of feed moisture and temperature of extrusion led to desirable expanded breakfast cereals, with a crispy texture, high water solubility, and attractive color, through the Response Surface Methodology. Regression models were established to predict responses by applying suitable feed moistures and temperatures. The optimal points were defined at 15.5% and 16.0% of feed moisture and at 159 °C and 150 °C of 4th barrel zone temperature for the black and red rice extrudates, respectively, which corresponded to the best technological properties of the snacks. It was demonstrated that pigmented rice varieties could be used successfully to produce very attractive colored breakfast cereal balls by extrusion with desirable expansion, texture and color properties.

Acknowledgements

The authors gratefully acknowledge the financial support of the National Council for Scientific and Technological Development (CNPq, 154614/2013-0) and the Santa Catarina Research Foundation (FAPESC, 177777/2013-0). Additionally, the authors would like to thank Dr. José A. Noldin from the Experimental Station of Itajaí for the supply of the rice samples, as well as Ms. Rosa M. C. Barros for her technical assistance.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Silvia Leticia Rivero Meza and Patricia Sinnecker have contributed equally.

References

- AACC . Approved methods of the American Association of Cereal Chemists, method 61-02.01 406 (RVA) 11. St. Paul: American Association of Cereal Chemists; 2012. [Google Scholar]

- Altan A, Mccarthy KL, Maskan M. Evaluation of snack food from barley–tomato blends by extrusion processing. J Food Eng. 2008;84:231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Anderson RA, Conway HF, Pfeifer VF, Griffin EL. Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci Today. 1969;14:4–12. [Google Scholar]

- AOAC . Approved methods of the American Association of Official Analytical Chemists. Gaithersburg: American Association of Official Analytical Chemists; 2000. [Google Scholar]

- Brennan MA, Monro JA, Brennan CS. Effect of inclusion of soluble and insoluble fibers into extruded breakfast cereal products made with reverse screw configuration. Int J Food Sci Technol. 2008;43:2278–2288. doi: 10.1111/j.1365-2621.2008.01867.x. [DOI] [Google Scholar]

- Chalermchaiwat P, Jangchud K, Jangchud A, Charunuch C, Prinyawiwatkul W. Antioxidant activity, free gamma-Aminobutyric acid content, selected physical properties and consumer acceptance of germinated brown rice extrudates as affected by extrusion process. LWT Food Sci Technol. 2015;30:155–163. [Google Scholar]

- Dalbhagat CG, Mahato DK, Mishra HN. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: a review. Trends Food Sci Technol. 2019;85:226–240. doi: 10.1016/j.tifs.2019.01.001. [DOI] [Google Scholar]

- Ding Q, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snack. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- González RJ, Cavada EP, Peña JV, Torres RL, De Greef DM, Drago SR. Extrusion conditions and amylose content affect physicochemical properties of extrudates obtained from brown rice grains. Int J Food Sci. 2013;2013:8. doi: 10.1155/2013/584148. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Leardkamolkarn V, Thongthep W, Suttiarporn P, Kongkachuichai R, Wongpornchai S, Wanavijitr A. Chemopreventive properties of the bran extracted from a newly-developed Thai rice: The Riceberry. Food Chem. 2011;125:978–985. doi: 10.1016/j.foodchem.2010.09.093. [DOI] [Google Scholar]

- Leyva-Corral J, Quintero-Ramos A, Camacho-Davila A, Zazueta-Morales JJ, Aguilar-Palazuelos E, Ruiz-Gutierrez MG, Melendez-Pizarro CO, Ruiz-Anchondo TJ. Polyphenolic compound stability and antioxidant capacity of apple pomace in an extruded cereal. LWT Food Sci Technol. 2016;65:228–236. doi: 10.1016/j.lwt.2015.07.073. [DOI] [Google Scholar]

- Martínez MM, Calviño A, Rosell CM, Gómez M. Effect of different extrusion treatments and particle size distribution on the physicochemical properties of rice flour. Food Bioprocess Technol. 2014;7:2657–2665. doi: 10.1007/s11947-014-1252-7. [DOI] [Google Scholar]

- Massaretto IL, Alves MFM, Mira NVM, Carmona AK, Marquez UML. Phenolic compounds in raw and cooked rice (Oryza sativa L.) and their inhibitory effect on the activity of angiotensin I-converting enzyme. J Cereal Sci. 2011;54:236–240. doi: 10.1016/j.jcs.2011.06.006. [DOI] [Google Scholar]

- Meng X, Threinen D, Hansen M, Driedger D. Effect of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res Int. 2010;43:650–658. doi: 10.1016/j.foodres.2009.07.016. [DOI] [Google Scholar]

- Mira NVM, Massaretto IL, Pascual CSCI, Marquez UML. Comparative study of phenolic compounds in different Brazilian rice (Oryza sativa L.) genotypes. J Food Compos Anal. 2009;22:405–409. doi: 10.1016/j.jfca.2008.06.012. [DOI] [Google Scholar]

- Montgomery DC. Design and analysis of experiment. New York: Wiley; 1991. [Google Scholar]

- Oliveira LC, Schmiele M, Steel CJ. Development of whole grain wheat flour extruded cereal and process impacts on color, expansion, and dry and bowl-life texture. LWT Food Sci Technol. 2017;75:261–270. doi: 10.1016/j.lwt.2016.08.064. [DOI] [Google Scholar]

- Oliveira LC, Alencar NMM, Steel CJ. Improvement of sensorial and technological characteristics of extruded breakfast cereals enriched with whole grain wheat flour and jabuticaba (Myrciaria cauliflora) peel. LWT Food Sci Technol. 2018;90:207–214. doi: 10.1016/j.lwt.2017.12.017. [DOI] [Google Scholar]

- Pardhi SD, Singh B, Nayik GA, Dar BN. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J Saudi Soc Agric Sci. 2016;18:7–16. [Google Scholar]

- Rocchetti G, Chiodelli G, Giubert G, Masoero F, Trevisan M, Lucini L. Evaluation of phenolic profile and antioxidant capacity in gluten-free flours. Food Chem. 2017;228:367–373. doi: 10.1016/j.foodchem.2017.01.142. [DOI] [PubMed] [Google Scholar]

- Shao Y, Hua Z, Yu Y, Moua R, Zhu Z, Beta T. Phenolic acids, anthocyanins, proanthocyanidins, antioxidant activity, minerals and their correlations in non-pigmented, red, and black rice. Food Chem. 2018;239:733–741. doi: 10.1016/j.foodchem.2017.07.009. [DOI] [PubMed] [Google Scholar]

- Shen Y, Jin L, Xiao P, Lu Y, Bao J. Total phenolics, flavonoids, antioxidant capacity in rice grain and their relations to grain color, size and weight. J Cereal Sci. 2009;49:106–111. doi: 10.1016/j.jcs.2008.07.010. [DOI] [Google Scholar]

- Tanaka J, Nakamura S, Tsuruma K, Shimazawa M, Shimoda H, Hara H. Purple rice (Oryza sativa L.) extract and its constituents inhibit VEGF-induced angiogenesis. Phytother Res. 2011;26:214–222. doi: 10.1002/ptr.3533. [DOI] [PubMed] [Google Scholar]

- Wickert E, Schiocchet MA, Noldin JA, Raimondi JV, Andrade A, Scheuermann KK, Marschalek R, Martins GN, Hickel E, Eberhardt DS, Knoblauch R. Exploring variability: New Brazilian varieties SCS119 Rubi and SCS120 Onix for the specialty rice markets. Open J Genet. 2014;4:157–165. doi: 10.4236/ojgen.2014.42016. [DOI] [Google Scholar]

- Xu E, Pan X, Wu Z, Long J, Li J, Xu X, Jin Z, Jiao A. Response surface methodology for evaluation and optimization of process parameter and antioxidant capacity of rice-flour modified by enzymatic extrusion. Food Chem. 2016;212:146–154. doi: 10.1016/j.foodchem.2016.05.171. [DOI] [PubMed] [Google Scholar]

- Yang SH, Peng J, Lui WB, Lin J. Effects of adlay species and rice flour ratio on the physicochemical properties and texture characteristic of adlay-based extrudates. J Food Eng. 2008;84:489–494. doi: 10.1016/j.jfoodeng.2007.06.010. [DOI] [Google Scholar]