Abstract

This study was evaluated the possibility of replacing some chemical additives in meat products by the Caesalpinia sappan L. (CS) extract. Four different types of cooked pork sausages were prepared by mixing nitrite with CS extracts at different concentration like control (without nitrite and extract), T1 (0.007% nitrite), T2 (0.004% nitrite + 0.05% extract) and T3 (0.1% extract). Physicochemical properties, sensory attributes, and antioxidant activity of the control and treatments were investigated. Ash contents and DPPH radical scavenging activity were significantly (P < 0.05) higher when pork sausages were processed with the addition of CS extracts. The rate of lipid oxidation significantly (P < 0.05) decreased in the case of CS extracts addition. By comparing with the control, all nitrite or CS extract resulted in significant (P < 0.05) lower L* values; however, 0.007% nitrite and 0.004% nitrite plus 0.05% CS extract pointed significantly (P < 0.05) higher a* values in all storage times. As well as, arrangement of CS extracts (0.05%) and nitrite (0.004%) in pork sausages displayed high gumminess and cohesiveness values (P < 0.05), stable springiness and chewiness, and significantly (P < 0.05) enhance overall acceptability scores as sensory attributes compared to the control sausage after 30 days of storage. Therefore, the CS extract (0.05%), which can act as a natural antioxidant, exert a positive effect with nitrite (0.004%) on the sensory acceptability and help to preserve the desired color of cooked pork sausages by reducing oxidation rate during cold storage.

Keywords: Cooked pork sausage, Caesalpinia sappan L. extract, Nitrite replacement, Lipid oxidation, Antioxidant activity, Physicochemical quality

Introduction

Cooked pork sausages prepared by use of a granulated mixture of meat, fat, salt and additives are public eaten as meat foodstuff in numerous territories. Lipid-derived reactive oxygen species and oxidized myoglobin byproducts initiate oxidation of meat (Estévez 2011) and drastically reduce quality attributes like color, flavor and nutritional values of meat (Petron et al. 2007). Also, meat tenderness, juiciness, myofibrillar swelling, and solubility quality is diminished due to protein oxidation (Lund et al. 2011). The balance between antioxidant and pro-oxidant compound govern the rate of oxidation (Ponnampalam et al. 2017).

Lipid oxidation can be lessened by adding an antioxidant to the products, in that way extending the storage time and conserving the food value of products. Nitrite salt is added in processed meat to impart the antioxidant activity, inhibit microbial growth and spoilage, develop flavor, fix actual red color and extend shelf life (Thomas et al. 2014). In Korea, the concentration of residual nitrite in meat products should be below 70 ppm. Additionally, nitrite is potentially toxic, showing chemical toxicity and carcinogenic (reactions with some biogenic amines and formulation of N-nitrosamines) effects in consumers (Honikel 2008). So, consumers may choose meat products with low or zero nitrite/nitrate content. In addition, the food industries are engaged themselves to uncover natural ingredients against synthetic additives due to health safety of concern people (Vossen et al. 2012).

Natural sources of high nitrate containing plants identified as celery, spinach, Swiss chard, and parsley (Rial et al. 2017; Sebranek et al. 2012). The alternative to using nitrite in meat products is substituting with natural elements. Researchers are trying to replace nitrite in formulated meat by use of extracts plants and vegetables with anti-oxidant features during the last few years (Lin et al. 2011; Riazi et al. 2016). Caesalpinia sappan L. (CS, Leguminosae family) is used as a red dye and it is used as traditional Oriental medicines because of its biological activities and phytochemical contents (Ma et al. 2014). It is also responsible for antioxidant and antimicrobial activity (Badami et al. 2003; Lim et al. 2007). To our knowledge, there is no previous report with regard to the physicochemical alteration in meat products occurring on using CS extract as a natural plant pigment which replaces the use of nitrite.

Therefore, the aim of this study was to investigate the effects of the CS extract on the physicochemical properties, antioxidant activity and sensory attributes of cooked pork sausages during cold storage. By using the gathered results, we planned to evaluate the possibility of exchanging some chemical additives in meat products by the extract of plant origin.

Materials and methods

Preparation of CS extract and analysis

The dried heartwood CS was purchased from the market and ground with a grinder (SMKA-4000, PN Poongnyun Co. Ltd., Ansan, Korea) and sieved through a 100 mesh screen. The extract of CS powder was obtained following the method of the reflux extraction process. Firstly, one-part of CS powder is mixed with five parts distilled water following (w/v) ratio and shifted for abstraction at 90 °C for 6 h (portion I). The remainders were extracted with distilled water (1:5) at 90 °C for 12 h (portion II). Then the two portions were joined and filter paper (What man no. 1) was used to strain out the liquid solutions and a vacuum rotary evaporator was used to concentrate it at 90 °C. The concentrated extracts were frozen dried and stored at − 70 °C until. The freeze-dried powder has used in the manufacturing of the pork sausages.

A mixture of (6:4 v/v) methanol and distilled water was used to extract CS metabolites from a UPLC system (Waters, Milford, MA, USA). An Acquity UPLC BEH C18 column (2.1 mm × 100 mm × 1.7 μM; Waters) neutralized by water with 0.1% formic acid and enriched in a gradient with acetonitrile with 0.1% formic acid at a flow rate of 0.35 mL/min for 10 min was needed to insert sample. The metabolites analysis and condition were carried out by Gu et al. (2017).

Preparation of cooked pork sausages

Pork loin (Castrated boar; Landrace♂ × Yorkshire♀ × Duroc♂; moisture 74.97%, protein 20.66%, fat 1.94%) and pork back fat (moisture 11.98%, fat 86.04%) was acquired from a native butchery house 2 d post slaughter in Jinju, Korea. The lean pork loin and back fat were ground separately through a 5-mm plate with a meat grinder (YW456, LEM products, OH, USA). 2.3 kg of sausage along with three replications for each treatment were manufactured following the same formulation in the meat processing laboratory. The basic formulation consisted of 67.5% pork lean meat, 18% pork back fat, 12.3% iced water, 1.5% salt, 0.2% sodium tripolyphosphate and 0.5% sugar. Four different types of pork sausages were considered: (1) without sodium nitrite or CS extract (control), (2) added with 0.007% sodium nitrite (T1), (3) added with 0.004% sodium nitrite + 0.05% CS extract (T2) and (4) added with 0.1% CS extract (T3). Now, put together all components in a mixer for mixing, then homogenized for 10 min at 15 °C in a silent cutter (K15E, TALSA, Zaragoza, Spain). After the preparation was complete, emulsified sausage was stuffed into collagen casings (Diameter 50 mm, New tech, Dague, Korea) with a sausage stuffing kit (838, LEM products, OH, USA). All sausage samples were then permitted to equilibrate at 4 °C for 24 h in a refrigerator. Next, the cooking of all sausages was done at 90 °C for 60 min in a chamber (COS-050E, KOSTEM, Gwangju, Korea) to obtain an overall internal temperature at 75 ± 2 °C. After cooking, all sausages were dipped in cool water for immediate cooling and stored at 4 °C for 24 h. The cooled sausages were packaged in polyethylene bags and stored at 4 °C for 1 month. The quality properties analyses were performed during the storage on 15 days intervals like 1 days, 15 days and 30 days.

Proximate composition and emulsion stability

The proximate composition of sausage batter, including moisture, crude protein, crude fat, and crude ash, was determined using AOAC (2000) methods.

The emulsion stability was measured following a modified method of Jiménez-Colmenero et al. (2005). The emulsion stability (ES) was calculated with Eq. 1, by determining the volume of the emulsified layer (V30 min) after maintaining samples at 70 °C for 30 min, VT is the total volume before centrifugation:

| 1 |

Instrumental texture analysis

Texture parameters were studied at room temperature with a texture analyzer (EZ-SX, Shimadzu Co., Kyoto, Japan). The sausages were allowed to equilibrate at room temperature for 30 min. Cores samples were taken from the central portion (2.0 cm height × 3.0 cm diameter). The conditions of texture analysis were as follows: load cell 500 N and 100 mm/min crosshead speed. The TPA curve method proposed by Bourne (1978) was used to analyze the texture parameters like hardness, cohesiveness, springiness, gumminess, and chewiness for each sample.

Color, pH and lipid oxidation

The color parameters of sausages were inspected via a colorimeter (CR 400, Minolta, Tokyo, Japan). Standardized with a white calibration plate (Y = 81.2; x = 0.3214; y = 0.3391) which resembled the CIE color (International Commission on Illumination L* for lightness, a* for redness b* for yellowness). For color measurement, three numbers of sausages from each formulation were sliced into three parts of 2 cm thickness where color was not affected by the background. Then the color value was measured randomly from the central part of each slice and used for statistical analysis. The Chromas [(a*2 + b*2)1/2] and hue angle [tan−1(b*/a*)] were calculated (CIE 1978).

The pH meter (MP230, Mettler Toledo, Greifensee, Switzerland) was used to detect the acidic condition of sausages. For this purpose, homogenized 3 g sample into 27 mL distilled water for 30 s using a Polytron homogenizer (T25 basic, IKA, Selangor, Malaysia) and keep the slurry to set at room temperature before pH measurement.

The TBA distillation procedure was exercised to perceive the content of Thiobarbituric acid-reactive substance (TBARS) in sausage samples following Buege and Aust (1978) method with some modification. The sample was investigated in a Spectrometer against a blank sample of 2 mL deionized distilled water and 4 mL of TBA/TCA solution at 531 nm. The lipid oxidation rate was conveyed by malondialdehyde (MDA) as mg per kg of samples.

Free radical scavenging activity (DPPH assay)

The DPPH radical scavenging activity was determined using the method described by Thaipong et al. (2006). 24 mg DPPH were dissolved into 100 mL methanol to make stock solution and kept it at − 0 °C until use. The chemical solution was prepared by mixing 10 mL stock solution with 45 mL methanol to the absorbance of 1.1 ± 0.02 unit at 515 nm using the spectrophotometer (Cary 60 UV–Vis, Agilent Technologies, CA, USA). Sausage sample extract (0.5 mL) was allowed to react with 2.5 mL of the DPPH solution for 2 h in the dark. Then the absorbance was taken at 517 nm. The residual radicals were calculated as followed:

where [DPPHBlank] is the absorbance of DPPH radicals in blank with distilled water instead of sample and [DPPHSample] is the absorbance of DPPH radicals in the sample.

Sensory analysis

A trained 12-member consisting of researchers from the Department of Animal Science at Gyeongsang National University, Korea evaluated sensory attributes. The panelist selection was performed according to Meilgaard et al. (1999). For sensory analysis, sausages were cut into cubes (2 cm3) and served at room temperature (25 °C) in a glass container (Pyrex®, Charleroi, PA, USA) with random code numbers. Each panelist evaluated three sausage samples from each treatment (4 × 3 = 12 samples per day) in three sessions. The sensory attributes of cooked sausages were a 9-point hedonic scale for different parameters in items of color (1 = very pale, 9 = very dark), flavor (1 = very weak, 9 = very strong), off-flavor (1 = very weak, 9 = very strong), juiciness (1 = very dry, 9 = very juicy), tenderness (1 = very harder, 9 = much softer), and overall acceptability (1 = very undesirable, 9 = very desirable).

Statistical analysis

For the sensory analysis, average scores of the panel for each treatment and storage time were used. For this study, the experiment was included a total of 36 observations (4 treatments × 3 storage times × 3 replications) for statistical analysis. All data were presented as mean values of three replications ± standard deviations and were analyzed using the proc ANOVA in SAS® program (version 9.3 SAS Institute, Inc., USA). Post-hoc test was used to Duncan’s multiple range tests which was determine to the differences of means against the treatments and storage (P < 0.05).

Results and discussion

Proximate composition and emulsion stability

The pork sausage batter formulated with different level of nitrite and CS extracts showed no statistically significant differences (P > 0.05) in the moisture, protein and fat contents compared to the control (Table 1). But, the addition of CS extracts to pork sausage batters’ resulted in little increase in the protein content, as compared with the control and other treatment. However, CS extracts treated sausages (T2 and T3) showed higher values and also significant differences (P < 0.05) in the ash contents than control and 0.007% nitrite (T1) sausages due to an addition of natural extract into the formulation (Ham et al. 2017).

Table 1.

Proximate composition and emulsion stability of pork sausage batter in added CS extract

| Treatments1 | ||||

|---|---|---|---|---|

| Control | T1 | T2 | T3 | |

| Proximate composition (%) | ||||

| Moisture | 62.97 ± 1.33 | 63.05 ± 0.93 | 61.91 ± 1.82 | 62.23 ± 1.40 |

| Protein | 18.48 ± 1.11 | 18.73 ± 0.68 | 19.23 ± 1.48 | 18.87 ± 0.66 |

| Fat | 16.37 ± 1.40 | 16.03 ± 1.11 | 16.62 ± 1.15 | 16.65 ± 1.30 |

| Ash | 2.18 ± 0.07B | 2.19 ± 0.09B | 2.24 ± 0.01A | 2.25 ± 0.03A |

| Emulsion stability (%) | ||||

| Water loss | 0.36 ± 0.14AB | 0.59 ± 0.24A | 0.29 ± 0.14B | 0.56 ± 0.29A |

| Fat loss | 5.45 ± 0.49 | 5.67 ± 0.44 | 6.65 ± 1.69 | 6.15 ± 1.04 |

| Total loss | 5.81 ± 0.63B | 6.26 ± 0.66B | 6.94 ± 1.83AB | 6.71 ± 1.33A |

All values are mean ± standard deviation. n = 3

A,BMeans within each row with different superscripts capital letters are significantly different (P < 0.05). Without capital letters means no significant difference in the column (P > 0.05)

1Control: no added, T1: sausage batter added with 0.007% sodium nitrite, T2: sausage batter added with 0.004% sodium nitrite and 0.05% CS extract, and T3: sausage batter added with 0.1% CS extract

Fat exudation studies showed no significant differences in fat-loss among the sausage batter samples (P > 0.05). The addition of 0.007% nitrite (T1) and 0.1% CS extract-added sausage (T3) had higher water loss than the control sausage; however, it exhibited no significant differences in water loss compared to the control (P > 0.05). Pork sausage batters prepared with 0.1% CS extract presented significantly higher total exudation than the control and 0.007% nitrite added sausages (P < 0.05). Emulsion stability is closely related to the binding capacity of raw materials (Youssef and Barbut 2009). The increased total loss in the sausage batters with CS extract resulted in the destabilization of the emulsion due to loss of water-binding capacity (Estévez et al. 2005).

Instrumental texture analysis

The better texture is related to the mouthfeel and other sensory characteristics of meat products. Table 2 shows the result of texture parameters for cooked pork sausages at the storage period. During cold storage, the control group had high values for hardness from the other samples and there are significant differences among all sausages. However, T1, T2, and T3 showed no statistically significant difference between them in hardness values during all storage time (P > 0.05). The hardness values of T2 treatment group decreased after addition of (0.05%) CS extracts with nitrite (0.004%) compared to other treatments. The addition of clove extracts decreased the hardness of Chinese-style sausages during chilled storage (Zhang et al. 2017). Also, protein oxidation may have a deleterious effect on the hardness of meat products. Zhang et al. (2013) reported that natural antioxidants may delay changes in the hardness of meat products by reducing emulsion destabilization and decreasing protein oxidation. Antioxidants may maintain the preservation of muscle membranes by inhibiting lipid oxidation and prevent moisture loss and changes into the texture of sausages (Estévez et al. 2006). In 30 days’ storage, the gumminess and cohesiveness of T1, T2, and T3 samples showed significantly higher values than those of control (P < 0.05); however, T1, T2, and T3 exhibited no significant differences in gumminess and cohesiveness among them (P > 0.05). Again, there were no significant differences in chewiness value among all groups of samples of the storage time of 1 and 15 days (P > 0.05), but the chewiness value of the nitrite-free (T3) sample was significantly lower than that of control and T1 in 30 days (P < 0.05). These results indicated that CS extract as natural pigment combine with nitrite can retard the degradation of sausage texture by exerting antioxidant effects.

Table 2.

Changes in texture profile analysis in added CS extract of cooked pork sausage during storage time at 4 °C

| Parameters/treatments1 | Storage time (days) | ||

|---|---|---|---|

| 1 | 15 | 30 | |

| Hardness (N) | |||

| C | 7.54 ± 0.71A | 7.35 ± 0.75A | 7.22 ± 0.75A |

| T1 | 6.94 ± 0.91AB | 6.79 ± 0.75AB | 6.86 ± 1.01AB |

| T2 | 6.58 ± 0.65B | 6.50 ± 0.50B | 6.55 ± 0.51B |

| T3 | 6.69 ± 0.59B | 6.59 ± 0.58B | 6.70 ± 0.51B |

| Cohesiveness (–) | |||

| C | 0.47 ± 0.04 | 0.49 ± 0.04B | 0.45 ± 0.03B |

| T1 | 0.49 ± 0.02 | 0.50 ± 0.03B | 0.49 ± 0.04A |

| T2 | 0.47 ± 0.03b | 0.51 ± 0.02ABa | 0.51 ± 0.05Aa |

| T3 | 0.46 ± 0.11b | 0.52 ± 0.03Aa | 0.49 ± 0.02Aab |

| Springiness (mm) | |||

| C | 17.92 ± 6.76A | 15.96 ± 6.84 | 16.89 ± 6.27A |

| T1 | 15.85 ± 6.51AB | 14.02 ± 6.17 | 15.55 ± 6.81AB |

| T2 | 15.62 ± 6.77AB | 13.88 ± 5.33 | 13.45 ± 5.43AB |

| T3 | 13.50 ± 5.08B | 12.71 ± 5.40 | 12.27 ± 4.48B |

| Gumminess (N) | |||

| C | 3.05 ± 0.36B | 2.93 ± 0.35C | 3.17 ± 0.36B |

| T1 | 3.63 ± 0.45A | 3.64 ± 0.32A | 3.52 ± 0.33A |

| T2 | 3.57 ± 0.34Aa | 3.24 ± 0.34Bb | 3.54 ± 0.60Aa |

| T3 | 3.17 ± 0.39B | 3.20 ± 0.32B | 3.29 ± 0.30AB |

| Chewiness (N * mm) | |||

| C | 55.23 ± 23.53 | 46.51 ± 20.18 | 54.37 ± 24.54A |

| T1 | 55.94 ± 18.96 | 50.46 ± 20.76 | 54.55 ± 23.65A |

| T2 | 55.46 ± 23.81 | 45.99 ± 22.43 | 45.81 ± 14.12AB |

| T3 | 42.51 ± 15.87 | 40.26 ± 15.98 | 39.99 ± 13.53B |

Data are mean ± standard deviation. n = 3

A,BMeans with different superscript capital letters in a column within each treatment differ significantly (P < 0.05)

a,bMeans with different superscript small letters in a row within at storage time differ significantly (P < 0.05). Without capital letters or small letters means no significant difference in the column or row (P > 0.05)

1Control: no added, T1: sausage batter added with 0.007% sodium nitrite, T2: sausage batter added with 0.004% sodium nitrite and 0.05% CS extract, and T3: sausage batter added with 0.1% CS extract

Instrumental color analysis

The color values were measured during storage and are presented in Table 3. The variation in meat color is associated with the formation of metmyoglobin from oxidized oxymyoglobin after slaughter to the final product (Gallego et al. 2015). L* (lightness) values of sausage groups of T2 and T3 were significantly lower than sausage groups of control and T1 at the storage time of 1 and 15 days (P < 0.05), but no significant differences showed between T2 and T3 (P > 0.05). Moreover, each sample showed significant differences in L* values among them after 30 days’ storage. The breakdown of heme pigments during storage might have led to this lower lightness value (Brannan 2009). The redness value (a*) is the most important color parameter for selection and rejection of meat based on freshness quality to the consumer. Here, a* values of 0.007% nitrite (T1) and 0.004% nitrite and 0.05% CS extract (T2) treated samples at all storage days were significantly higher than those of other treatments (P < 0.05). At the completion of the storage time, the intensity of b* (yellowness) for 0.1% CS extract (T3) added sausage was significantly higher than those of other treatments (P < 0.05). Also, the b* values of the 0.007% nitrite (T1) and 0.004% nitrite and 0.05% CS extract (T2) treated samples were significantly lower than those of the control in 15 days’ storage (P < 0.05). However, the natural plant extracts affected meat color, specifically redness and yellowness. Again, T3 presented significantly higher chromas and hue angle values than those of other treatments after 30 days’ storage time (P < 0.05). Likewise, the intensity of each color parameter at the end of the 30 days’ cold storage was significantly lowered (P < 0.05) than the value measured at the day 1 as a result of the oxidation process, leading in this way to a change in color. Pork sausages did discolor over storage time due to oxygen consumption and pigment oxidation. Also, the myoglobin content of the muscle increase redness values a* (Latou et al. 2014). Based on these results, 004% nitrite with 0.05% CS extract has a vital effect on the natural red color of cooked pork sausages without affecting the initial color.

Table 3.

Changes in color in added CS extract of cooked pork sausage during storage time at 4 °C

| Parameters/treatments1 | Storage time (days) | ||

|---|---|---|---|

| 1 | 15 | 30 | |

| L* (Lightness) | |||

| C | 80.90 ± 0.65Aa | 80.15 ± 0.79Ab | 79.93 ± 0.41Ab |

| T1 | 79.21 ± 0.96B | 79.47 ± 0.55B | 79.39 ± 0.79B |

| T2 | 78.52 ± 1.11C | 78.62 ± 0.98C | 78.76 ± 0.96C |

| T3 | 78.71 ± 0.92C | 78.55 ± 1.17C | 78.26 ± 1.24D |

| a* (Redness) | |||

| C | 0.44 ± 0.33Bb | 0.31 ± 0.30Bb | 3.43 ± 2.39Ba |

| T1 | 3.90 ± 0.72Ab | 2.97 ± 0.88Ac | 5.31 ± 1.94Aa |

| T2 | 3.75 ± 0.39Ab | 3.02 ± 0.69Ac | 5.10 ± 1.82Aa |

| T3 | 0.66 ± 0.20Bb | 0.36 ± 0.22Bb | 2.02 ± 1.12Ca |

| b* (Yellowness) | |||

| C | 13.06 ± 0.29Ba | 13.62 ± 0.46Ba | 11.00 ± 2.38Bb |

| T1 | 11.62 ± 0.25Db | 12.55 ± 0.93Ca | 10.10 ± 2.29Bc |

| T2 | 12.18 ± 0.34Cb | 12.83 ± 0.74Ca | 10.61 ± 1.88Bc |

| T3 | 13.87 ± 0.39Aa | 14.09 ± 0.26Aa | 12.71 ± 1.69Ab |

| Chroma (∆C) | |||

| C | 13.07 ± 0.28Bb | 13.62 ± 0.46Ba | 11.89 ± 1.49Bc |

| T1 | 12.27 ± 0.40Db | 12.94 ± 0.74Ca | 11.72 ± 1.17Bc |

| T2 | 12.66 ± 0.31Cb | 13.20 ± 0.59Ca | 12.01 ± 0.92Bc |

| T3 | 13.88 ± 0.39Aa | 14.14 ± 0.27Aa | 12.92 ± 1.47Ab |

| Hue angle (h) | |||

| C | 91.88 ± 1.51Aa | 90.28 ± 1.70Ba | 70.94 ± 14.92Bb |

| T1 | 71.61 ± 0.30Cb | 76.55 ± 4.60Ca | 61.15 ± 13.67Cc |

| T2 | 72.81 ± 1.80Bb | 76.70 ± 3.61Ca | 63.57 ± 11.77Cc |

| T3 | 92.67 ± 0.81Aa | 94.81 ± 0.90Aa | 84.27 ± 9.99Ab |

Data are mean ± standard deviation. n = 3

A–DMeans with different superscript capital letters in a column within each treatment differ significantly (P < 0.05)

a–cMeans with different superscript small letters in a row within at storage time differ significantly (P < 0.05)

1Control: no added, T1: sausage batter added with 0.007% sodium nitrite, T2: sausage batter added with 0.004% sodium nitrite and 0.05% CS extract, and T3: sausage batter added with 0.1% CS extract

pH, lipid oxidation and antioxidant activity

The pH, TBARS and DPPH radical scavenging activity were measured during storage and are presented in Table 4. The pH values for all treatment samples significantly increased from 30 days of storage from storage times of 1 and 15 days (P < 0.05). T1 and T2 displayed no major dissimilarities in pH values after 30 days (P > 0.05). However, control and T3 showed a significant increase in pH values compared to that of T1 and T2 (P < 0.05). The low pH values in T1 and T2 could be a concern for retention of the produced nitrite, and nitrous acid was created from nitrite promptly in the acid medium (Sebranek and Fox 1985). Whereas, the high pH values in control and T3 may be due to the accumulation of metabolites by the generation of ammonia from deamination of proteins (Biswas et al. 2004).

Table 4.

Changes in pH, TBARS and DPPH radical scavenging activity in added CS extract of cooked pork sausage during storage time at 4 °C

| Parameters/treatments1 | Storage time (days) | ||

|---|---|---|---|

| 1 | 15 | 30 | |

| pH | |||

| C | 6.20 ± 0.06b | 6.22 ± 0.05b | 6.59 ± 0.39Aa |

| T1 | 6.20 ± 0.06b | 6.22 ± 0.05b | 6.27 ± 0.07Ba |

| T2 | 6.23 ± 0.10ab | 6.20 ± 0.02b | 6.30 ± 0.14Ba |

| T3 | 6.20 ± 0.05b | 6.18 ± 0.07b | 6.63 ± 0.18Aa |

| TBARS (mg MDA/kg) | |||

| C | 0.75 ± 0.17Ab | 1.23 ± 0.14Aa | 1.20 ± 0.21Aa |

| T1 | 0.35 ± 0.04C | 0.53 ± 0.29B | 0.54 ± 0.13B |

| T2 | 0.37 ± 0.03Cb | 0.49 ± 0.21Ba | 0.52 ± 0.11Ba |

| T3 | 0.48 ± 0.06Bb | 0.49 ± 0.16Bb | 0.64 ± 0.16Ba |

| DPPH (%) | |||

| C | 48.00 ± 4.29Ba | 39.55 ± 8.26Cb | 35.03 ± 8.70Dc |

| T1 | 41.08 ± 5.05C | 41.37 ± 10.67C | 40.96 ± 8.11C |

| T2 | 50.48 ± 3.25B | 47.40 ± 13.08B | 48.82 ± 2.92B |

| T3 | 53.43 ± 3.67A | 56.43 ± 3.61A | 57.42 ± 8.40A |

Data are mean ± standard deviation. n = 3

A–DMeans with different superscript capital letters in a column within each treatment differ significantly (P < 0.05)

a–cMeans with different superscript small letters in a row within at storage time differ significantly (P < 0.05)

1Control: no added, T1: sausage batter added with 0.007% sodium nitrite, T2: sausage batter added with 0.004% sodium nitrite and 0.05% CS extract, and T3: sausage batter added with 0.1% CS extract

TBARS values of control, T2, and T3 groups of cooked pork sausage amplified significantly as the storage times elongated (P < 0.05). All sample treated with nitrite and CS extract exhibited significantly lower TBARS values, as compared to those of the control after 30 days (P < 0.05). The TBARS values of the CS extract treatments showed a similar profile as that of the cooked pork sausages containing nitrite. Furthermore, higher CS extracts contents (T3), as well as the addition of nitrite (T1 and T2), resulted in lower TBARS values than those in the controls. The reduction in TBARS values could be attributed to the reaction to malondialdehyde with amino acids, sugars, and nitrite complex formulations (Janero 1990). In addition, lipid oxidation is prohibited by the antioxidant action of nitrite. Honikel (2008) reported that meat product cured by nitrite interacts with the oxidation processes by the formation of myoglobin stable compounds, which make iron inaccessible. Similarly, raw and cooked pork patties containing several plant extracts showed decreased TBARS values and less oxidation rate during storage. The addition of 1% grape pomace, in combination with reduced nitrite levels, to cooked beef sausages showed lower lipid oxidation (Riazi et al. 2016). Vossen et al. (2012) found lower TBARS values in liver pâtés on lowering the sodium nitrite concentration and increasing the sodium ascorbate concentration. Therefore, (0.05%) CS extract with (0.004%) nitrite in cooked pork sausages is enough to retard lipid oxidation and improve product safety for consumption.

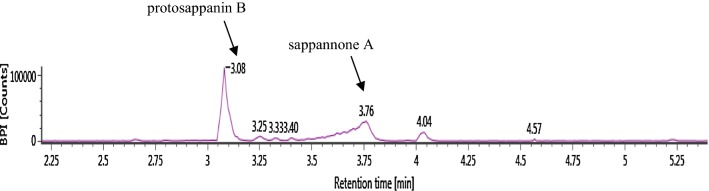

Compared to the control, all frozen samples had significantly greater DPPH values after 30 days (P < 0.05). When compared with control and T1, the DPPH radical scavenging activity of samples made by 0.05% and 0.1% CS extract was significantly developed. Furthermore, sausage with added 0.1% CS extract (T3) showed significantly the highest DPPH values among all treatments of sausage during 30 days of storage (P < 0.05). This implies that the level of antioxidant activity depends on the amount of CS extract. Moreover, treatments such as T1, T2, and T3 showed significant differences in radical scavenging activity of each other (P < 0.05) but in storage time, there was no significant difference in scavenging role as time being (P > 0.05). Previous phytochemical investigations into CS have many isolated compounds which display antibacterial and antioxidative characteristics (Ma et al. 2014). The 1′,4′-Dihydrospiro[benzofuran-3(2H),3′-[3H-2] benzopyran]-1′,6′,6′,b7′-tetrol and 3-[[4,5-dihydroxy-2(hydroxymethyl)phenyl]-methyl]-2,3-dihydro-3,6-benzofurandiol from CS retained identical radical scavenging activities as like as ascorbic acid (Safitri et al. 2003). Furthermore, phenolic compounds of plant extract played the vital role of scavenging free radicals and prevent oxidation of meat. The antioxidative activity of CS is considered to originate from metabolites such as protosappanin B and sappanone A (Fig. 1). So, CS was considered to have a sufficiently potent activity for use as a natural antioxidant in processed meat.

Fig. 1.

Presentative ultra-performance liquid chromatography-quadrupole-time-of-flight mass spectrometry (UPLC-Q-TOF MS) profiles of CS extract. For LC/MS analysis, the metabolites were analyzed with a UPLC-BEH C18 column (2.1 mm × 100 mm × 1.7 μm) and by Q-TOF MS in ESI-positive mode

Sensory attributes

The sensory attributes were evaluated during storage and are presented in Table 5. In general, the nitrite or CS extracts treated samples appeared to be more effective than the control for preferable sensory attributes. T2 showed significantly higher color scores than the other treatment samples after 15 days (P < 0.05). Also, the color scores were significantly higher in the 0.004% nitrite plus 0.05% CS extracts (T2) and 0.1% CS extracts (T3) treatments than those of the control after 30 days (P < 0.05). Subjective color scores indicated that nitrite or CS extract-treatments tended to be darker than the control. In comparison, L* values (Table 3) indicated nitrite or CS extract-treatment samples to be darker and these samples had higher color scores, as compared with those of the control.

Table 5.

Changes in sensory attributes in added CS extract of cooked pork sausage during storage time at 4 °C

| Attributes/treatments1 | Storage time (days) | ||

|---|---|---|---|

| 1 | 15 | 30 | |

| Color | |||

| C | 4.00 ± 1.58 | 4.80 ± 1.10B | 3.67 ± 1.21B |

| T1 | 5.00 ± 0.12b | 6.00 ± 0.71ABa | 5.33 ± 0.82ABab |

| T2 | 5.20 ± 0.40 | 6.20 ± 1.64A | 5.83 ± 0.75A |

| T3 | 5.00 ± 1.22 | 5.60 ± 1.82AB | 5.50 ± 1.05A |

| Flavor | |||

| C | 4.80 ± 0.55 | 4.80 ± 1.10B | 5.83 ± 1.17 |

| T1 | 5.00 ± 1.73 | 5.40 ± 1.14A | 5.83 ± 0.98 |

| T2 | 4.80 ± 0.84 | 5.40 ± 0.89A | 5.00 ± 0.89 |

| T3 | 5.00 ± 1.00 | 4.60 ± 0.89B | 4.50 ± 0.84 |

| Off-flavor | |||

| C | 2.00 ± 1.00Ab | 2.20 ± 0.84Ab | 4.00 ± 0.89Aa |

| T1 | 1.00 ± 0.45Bb | 1.83 ± 0.75Bab | 2.60 ± 1.67Ba |

| T2 | 1.40 ± 0.55AB | 1.67 ± 0.82B | 2.20 ± 1.30B |

| T3 | 2.00 ± 1.00A | 2.00 ± 0.20AB | 2.50 ± 1.38B |

| Juiciness | |||

| C | 4.60 ± 1.14B | 4.30 ± 0.85B | 4.33 ± 1.03 |

| T1 | 4.80 ± 1.30B | 5.60 ± 0.89A | 4.83 ± 0.98 |

| T2 | 5.20 ± 0.45AB | 6.00 ± 1.22A | 5.50 ± 1.05 |

| T3 | 5.40 ± 1.52A | 5.00 ± 0.94AB | 6.00 ± 0.80 |

| Tenderness | |||

| C | 3.60 ± 0.89B | 3.80 ± 0.84B | 5.00 ± 0.89 |

| T1 | 5.60 ± 1.52A | 6.20 ± 0.84A | 5.33 ± 1.03 |

| T2 | 6.20 ± 1.30A | 6.00 ± 1.00A | 6.17 ± 0.98 |

| T3 | 4.60 ± 1.14AB | 5.60 ± 0.89A | 5.17 ± 1.72 |

| Overall acceptability | |||

| C | 4.20 ± 1.30B | 4.80 ± 0.84B | 4.80 ± 0.80B |

| T1 | 6.00 ± 1.00A | 5.40 ± 0.89B | 5.83 ± 0.75AB |

| T2 | 5.80 ± 1.30AB | 7.00 ± 0.71A | 6.50 ± 0.84A |

| T3 | 4.60 ± 1.14AB | 5.20 ± 0.45B | 5.00 ± 1.26B |

Data are mean ± standard deviation. n = 3

A,BMeans with different superscript capital letters in a column within each treatment differ significantly (P < 0.05)

a,bMeans with different superscript small letters in a row within at storage time differ significantly (P < 0.05). Without capital letters or small letters means no significant difference in the column or row (P > 0.05)

1Control: no added, T1: sausage batter added with 0.007% sodium nitrite, T2: sausage batter added with 0.004% sodium nitrite and 0.05% CS extract, and T3: sausage batter added with 0.1% CS extract

Flavor was significantly higher in T1 and T2 samples, as compared with those of all other samples on day 15 (P < 0.05). Again, the off-flavor scores were significantly lower in the T1, T2, and T3 samples than those in the control at the storage time of 30 days (P < 0.05). Color, off-flavor, and juiciness were affected by lipid oxidation in meat products. The role of nitrite is important in determining color and oxidation stability of meat products (Sebranek and Bacus 2007; Vossen et al. 2012). CS extracts to possess antioxidant activity, and its utility against harmful oxidation should be explored. On day 1, T3 showed significantly higher juiciness scores compared to those of control and T1 (P < 0.05). Then again, T1 and T2 showed significantly higher juiciness scores than those of the control at 15 days’ storage (P < 0.05). The tenderness scores were significantly higher in all the treated samples (T1, T2, and T3), as compared with the control after day 15 (P < 0.05). But, cooked pork sausages treated with 0.007% nitrite (T1), 0.004% nitrite plus 0.05% CS extracts (T2) and 0.1% CS extracts (T3) showed no significant differences among them during the storage days of 1 and 15 (P > 0.05). Furthermore, T1 had a significantly higher score of overall acceptability than that of the control at day 1 (P < 0.05). The overall acceptability scores were significantly higher in T2 sausage sample, as compared to those of all other sausage samples at day 15 (P < 0.05). Also, the whole acceptability scores were significantly higher in the 0.004% nitrite plus 0.05% CS extracts (T2) treatment, as compared to those of the control after 30 days (P < 0.05). Therefore, adding natural antioxidants can be considered to have a positive effect on the sensory attributes of meat products. It was determined that the addition of 0.05% CS extracts from 0.004% nitrite is adequate to produce the desired sensory properties in cooked pork sausages.

Conclusion

The present findings suggested that the addition of CS extracts is not very effective against improving the physical properties of cooked pork sausages. But, incorporation of CS extracts with nitrite into cooked pork sausages significantly affected the ash content, hardness, gumminess, cohesiveness, chewiness, redness, tenderness, overall acceptability and also decreased lightness and off-flavor production. So, utilization of (0.05%) Caesalpinia sappan L. extract as a natural pigment with (0.004%) nitrite to improve oxidative (protein and lipid) stability was recommended for extending shelf-life of cooked pork sausages during cold storage. Our study will be helpful in leading further experiments on the application of antioxidants from natural sources in meat products to reduce the negative health impact of the consumer.

Acknowledgements

This research was supported by the Korea Institute of Planning and Evaluation for Technology in Food Agriculture, Forestry and Fisheries, Ministry of Agriculture, Food and Rural Affairs (Project No. 316064-02-2-HD030).

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Jin-Kyu Seo and Rashida Parvin have contributed equally to this work.

Contributor Information

Jin-Kyu Seo, Email: mysjk14@naver.com.

Rashida Parvin, Email: rakhiparvin@yahoo.com.

Dong-Gyun Yim, Email: tousa0994@naver.com.

Md Ashrafuzzaman Zahid, Email: zahid_24jstu@yahoo.com.

Han-Sul Yang, Phone: +82-55-772-1948, Email: hsyang@gnu.ac.kr.

References

- A.O.A.C 17th edn . Official methods of analysis. Gaithersburg, MD: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Badami S, Moorkoth S, Rai SR, Kannan E, Bhojrai S. Antioxidant activity of Caesalpinia sappan heartwood. Biol Pharm Bull. 2003;26:1534–1537. doi: 10.1248/bpb.26.1534. [DOI] [PubMed] [Google Scholar]

- Biswas AK, Keshri RC, Bisht GS. Effect of enrobing and antioxidants on quality characteristics of precooked pork patties under chilled and frozen storage conditions. Meat Sci. 2004;66(3):733–741. doi: 10.1016/j.meatsci.2003.07.006. [DOI] [PubMed] [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- Brannan R. Effect of grape seed extract on descriptive sensory analysis of ground chicken during refrigerated storage. Meat Sci. 2009;81:589–595. doi: 10.1016/j.meatsci.2008.10.014. [DOI] [PubMed] [Google Scholar]

- Buege JA, Aust SD. Microsomal lipid peroxidation. Methods Enzymol. 1978;52:302–310. doi: 10.1016/S0076-6879(78)52032-6. [DOI] [PubMed] [Google Scholar]

- CIE (Commission Internationale de l’Eclairage) (1978) Recommendations on uniform color spaces–color difference equations, psychometric color terms. Supplement No. 2 to CIE Publication No. 15 (E-1.3.1) 1971/(TC-1–3). Paris

- Estévez M. Review protein carbonyls in meat systems: a review. Meat Sci. 2011;89:259–279. doi: 10.1016/j.meatsci.2011.04.025. [DOI] [PubMed] [Google Scholar]

- Estévez M, Ventanas S, Cava R. Protein oxidation in frankfurters with increasing levels of added rosemary essential oil: effect on color and texture deterioration. J Food Sci. 2005;70(7):427–432. doi: 10.1111/j.1365-2621.2005.tb11464.x. [DOI] [Google Scholar]

- Estévez M, Ventanas S, Cava R. Effect of natural and synthetic antioxidants on protein oxidation and color and texture changes in refrigerated stored porcine liver pâté. Meat Sci. 2006;74:396–403. doi: 10.1016/j.meatsci.2006.04.010. [DOI] [PubMed] [Google Scholar]

- Gallego MG, Gordon MH, Segovia FJ, Almajano MP. Caesalpinia decapetala extracts as inhibitors of lipid oxidation in beef patties. Molecules. 2015;20(8):13913–13926. doi: 10.3390/molecules200813913. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gu EJ, Kim DW, Jang GJ, Song SH, Lee JI, Lee SB, Kim BM, Cho Y, Lee HJ, Kim HJ. Mass-based metabolomic analysis of soybean sprouts during germination. Food Chem. 2017;217:311–319. doi: 10.1016/j.foodchem.2016.08.113. [DOI] [PubMed] [Google Scholar]

- Ham YK, Hwang KE, Song DH, Kim YJ, Shin DJ, Kim K, Lee HJ, Kim NR, Kim CJ. Lotus (Nelumbo nucifera) rhizome as an antioxidant dietary fiber in cooked sausage: effects on physicochemical and sensory characteristics. Korean J Food Sci Anim Resour. 2017;37(2):219–227. doi: 10.5851/kosfa.2017.37.2.219. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Honikel KO. The use and control of nitrate and nitrite for the processing of meat products. Meat Sci. 2008;78:68–76. doi: 10.1016/j.meatsci.2007.05.030. [DOI] [PubMed] [Google Scholar]

- Janero DR. Malonaldehyde and thiobarbituric acid-reactivity as diagnostics indices of lipid peroxidation and peroxidative tissue injury. Free Radic Biol Med. 1990;9:515–540. doi: 10.1016/0891-5849(90)90131-2. [DOI] [PubMed] [Google Scholar]

- Jiménez-Colmenero F, Ayo MJ, Carballo J. Physicochemical properties of low sodium frankfurter with added walnut: effect of transglutaminase combined with caseinate, KCl and dietary fiber as salt replacers. Meat Sci. 2005;69:781–788. doi: 10.1016/j.meatsci.2004.11.011. [DOI] [PubMed] [Google Scholar]

- Latou E, Mexis SF, Badeka AV, Kontakos S, Kontominas MG. Combined effect of chitosan and modified atmosphere packaging for shelf life extension of chicken breast fillets. Lebensm Wiss Technol. 2014;55:263–268. doi: 10.1016/j.lwt.2013.09.010. [DOI] [Google Scholar]

- Lim MY, Jeon JH, Jeong EY, Lee CH, Lee HS. Antimicrobial activity of 5-hydroxy-1,4-naphthoquinone isolated from Caesalpinia sappan toward intestinal bacteria. Food Chem. 2007;100:1254–1258. doi: 10.1016/j.foodchem.2005.12.009. [DOI] [Google Scholar]

- Lin Y, Huang M, Zhou G, Zou Y, Xu X. Prooxidant effects of the combination of green tea extract and sodium nitrite for accelerating lipolysis and lipid oxidation in pepperoni during storage. J Food Sci. 2011;76:C694–C700. doi: 10.1111/j.1750-3841.2011.02187.x. [DOI] [PubMed] [Google Scholar]

- Lund MN, Heinonen M, Baron CP, Estévez M. Protein oxidation in muscle foods: a review. Mol Nutr Food Res. 2011;55:83–95. doi: 10.1002/mnfr.201000453. [DOI] [PubMed] [Google Scholar]

- Ma GX, Zhu YD, Sun ZH, Yuan JQ, XieY Zhang XP, Tian Y, Yang JS, Wu HF, Xu XD. Three new cassane diterpenes from the seeds of Caesalpinia sappan. Phytochem Lett. 2014;8:141–144. doi: 10.1016/j.phytol.2014.03.008. [DOI] [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. 3. Boca Raton, FL: CRC Press; 1999. p. 354. [Google Scholar]

- Petron MJ, Raes K, Claeys E, Louren M, Fremaut D, De Smet S. Effect of grazing pastures of different botanical composition on antioxidant enzyme activities and oxidative stability of lamb meat. Meat Sci. 2007;75:737–745. doi: 10.1016/j.meatsci.2006.10.010. [DOI] [PubMed] [Google Scholar]

- Ponnampalam EN, Plozza T, Kerr MG, Linden N, Mitchell M, Bekhit AA, Hopkins DL. Interaction of diet and long ageing period on lipid oxidation and color stability of lamb meat. Meat Sci. 2017;129:43–49. doi: 10.1016/j.meatsci.2017.02.008. [DOI] [PubMed] [Google Scholar]

- Rial G, Boulaaba A, Popp J, Klein G. Effects of parsley extract powder as an alternative for the direct addition of sodium nitrite in the production of mortadella-type sausages—impact on microbiological, physicochemical and sensory aspects. Meat Sci. 2017;131:166–175. doi: 10.1016/j.meatsci.2017.05.007. [DOI] [PubMed] [Google Scholar]

- Riazi F, Zeynail F, Hoseini E, Behmadi H, Savadkoohi S. Oxidation phenomena and color properties of grape pomace on nitrite-reduced meat emulsion systems. Meat Sci. 2016;121:350–358. doi: 10.1016/j.meatsci.2016.07.008. [DOI] [PubMed] [Google Scholar]

- Safitri R, Tarigan P, Freisleben HJ, Rumampuk RJ, Murakami A. Antioxidant activity in vitro of two aromatic compounds from Caesalpinia sappan L. BioDactors. 2003;19(1–2):71–77. doi: 10.1002/biof.5520190109. [DOI] [PubMed] [Google Scholar]

- Sebranek JG, Bacus JN. Cured meat products without direct addition of nitrate or nitrite: what are the issues? Meat Sci. 2007;77:136–147. doi: 10.1016/j.meatsci.2007.03.025. [DOI] [PubMed] [Google Scholar]

- Sebranek JG, Fox JB., Jr A review of nitrite and chloride chemistry: interactions and implications for cured meats. J Sci Food Agric. 1985;36:1169–1182. doi: 10.1002/jsfa.2740361122. [DOI] [Google Scholar]

- Sebranek JG, Jackson-Davis AL, Myers KL, Lavieri NA. Beyond celery and starter culture: advances in natural/organic curing processes in the United States. Meat Sci. 2012;92:267–273. doi: 10.1016/j.meatsci.2012.03.002. [DOI] [PubMed] [Google Scholar]

- Thaipong K, Boonprakob U, Crosby K, Cisneros-Zevallos L, Byrne DH. Comparison of ABTS, DPPH, FRAP, and ORAC assays for estimating antioxidant activity from guava fruit extracts. J Food Compos Anal. 2006;19:669–675. doi: 10.1016/j.jfca.2006.01.003. [DOI] [Google Scholar]

- Thomas VH, Julie VB, Lynn V, Els V, John VC, Stefaan DS. Nitrite curing of chicken, pork, and beef inhibits oxidation but does not affect N-nitroso compound (NOC)-specific DNA adduct formation during in vitro digestion. J Agric Food Chem. 2014;62:1980–1988. doi: 10.1021/jf4057583. [DOI] [PubMed] [Google Scholar]

- Vossen E, Utrera M, De Smet S, Morcuende D, Estévez M. Dog rose (Rosa canina L.) as a functional ingredient in porcine frankfurters without added sodium ascorbate and sodium nitrite. Meat Sci. 2012;92:451–457. doi: 10.1016/j.meatsci.2012.05.010. [DOI] [PubMed] [Google Scholar]

- Youssef MK, Barbut S. Effects of protein level and fat/oil on emulsion stability, texture, microstructure, and color of meat batters. Meat Sci. 2009;82:228–233. doi: 10.1016/j.meatsci.2009.01.015. [DOI] [PubMed] [Google Scholar]

- Zhang L, Lin YH, Leng XJ, Huang M, Zhou GH. Effect of sage (Salvia officinalis) on the oxidative stability of Chinese-style sausage during refrigerated storage. Meat Sci. 2013;95:145–150. doi: 10.1016/j.meatsci.2013.05.005. [DOI] [PubMed] [Google Scholar]

- Zhang H, Peng X, Li X, Wu J, Guo X. The application of clove extract protects Chinese-style sausages against oxidation and quality deterioration. Korean J Food Sci Anim Resour. 2017;37(1):114–122. doi: 10.5851/kosfa.2017.37.1.114. [DOI] [PMC free article] [PubMed] [Google Scholar]