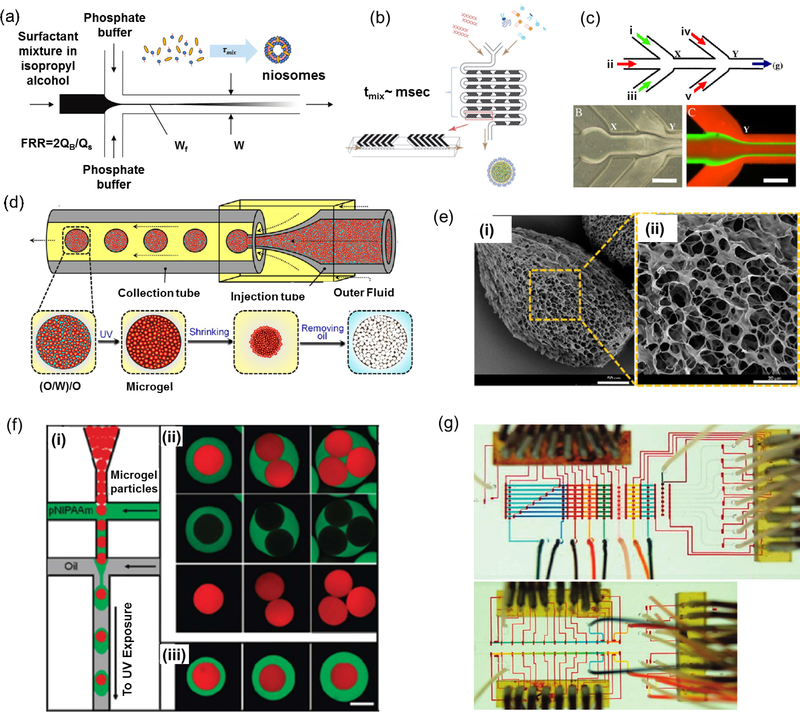

Figure 1.

Microfluidic platforms for production of drug and gene carriers. a) Schematics of niosome self-assembly via HFF in a diffusion-based microfluidic mixer (10 nm < Dp <100 nm); reprint with permission from[20]. b) Fabrication of lipid nanoparticle (LNP) small interfering RNA (siRNA) formulation strategy employing the staggered herringbone micromixer (20 nm < Dp < 100 nm); reprint with permission from[29]. c) A multi-inlet microfluidic HFF system to generate lipopolyplex containing Bcl-2 antisense deoxyoligonucleotide (100 nm < Dp < 300 nm); reprint with permission from[30]. d) Droplet-based microfluidic platform for open-celled porous poly(N-isopropylacrylamide) (PNIPAM) microgel production (150 μm < Dp < 450 μm), e) SEM micrographs of fabricated PNIPAM microgels with open-celled porous structure; reprint with permission from [32] f) Fabrication of microgel capsules that consist of two miscible yet distinct layers using double emulsion template in the droplet-based microfluidic device (20 μm < Dp < 100 μm); reprint with permission from [6]. g) Programmable microfluidic array for producing a combinatorial library of DNA encapsulated supramolecular particles; reprint with permission from (40 nm < Dp < 200 μm) [44].