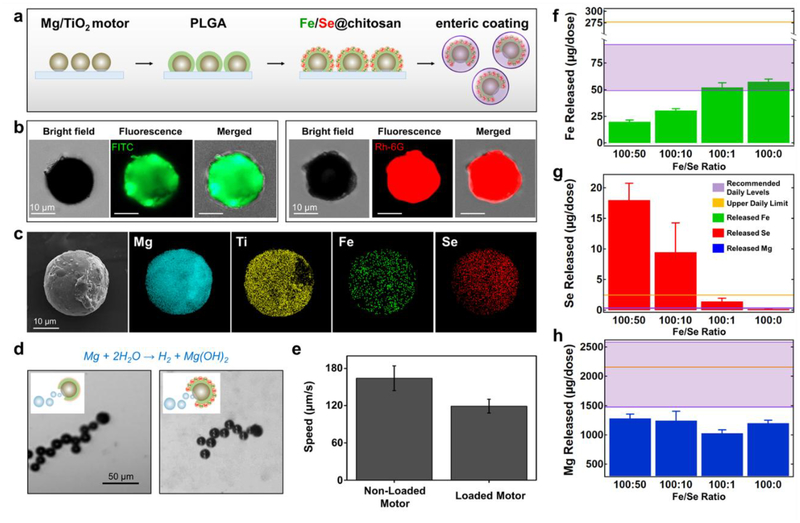

Figure 2.

Micromotor preparation, structural characterization and mineral loading. a, Schematic of the micromotor preparation. TiO2 is deposited over Mg microparticles dispersed over a glass slide, a PLGA film is coated over the Mg/TiO2 micromotors, Fe and Se are loaded via a chitosan film, and an enteric layer is coated over the mineral-loaded micromotors with the pH-responsive polymer Eudragit L100–55. b, Demonstration of the Fe and Se loading: iron(II) gluconate hydrate (left) and sodium selenate decahydrate (right) loaded in FITC or Rh-6G-labeled chitosan films, respectively. The microscopy images (optical, fluorescence: GFP and RFP channels, and merged) demonstrate the loading of the Fe and Se-based compounds over the Mg-based micromotors. c, SEM image of a Mg/TiO2/PLGA/Fe-Se@chitosan micromotor and EDX images illustrating the distribution of elemental Mg (cyan), Ti (yellow), Fe (green), and Se (red). d, Microscopic images (corresponding to Video S1) and schematic insets displaying the hydrogen bubble generation and the motion of a non-loaded (left) and a mineral-loaded (right) micromotor in intestinal fluid simulant (pH ~6.5) supplemented with 0.2% Triton X-100 (used as surfactant). e, Comparison of the non-loaded and mineral-loaded micromotor speeds in simulated intestinal fluid (n = 3, mean ± SD). f-h, Released elemental Fe (f), Se (g), and Mg (h) per treatment dosage (2 mg of Fe/Se-loaded micromotors) as a function of different ratios of the Fe and Se compounds used to prepare mineral-loaded micromotors (n = 4, mean ± SD). Two mg of mineral-loaded micromotors, dissolved in 0.1 M hydrochloric acid solution, were used to perform the ICP-OES analysis. The purple window indicates the recommended daily intake levels, and the gold line indicates the upper daily limit of both elements.