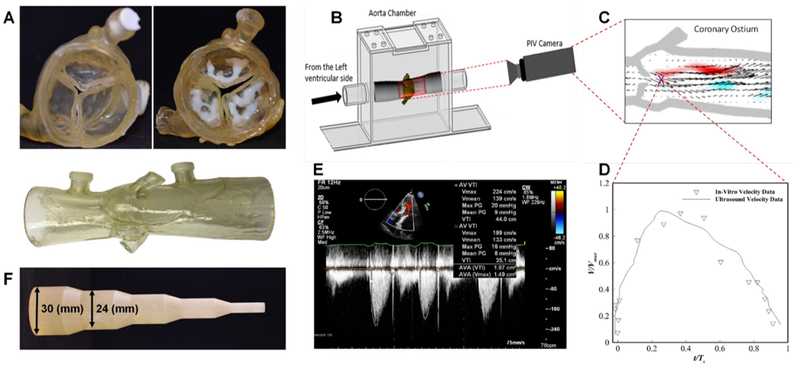

Figure 3.

The 3D printed aortic root model was manufactured from TangoPlus material, VeroWhite material was used for calcium nodule, both printed using Connex 350 3D printer (Stratasys, Eden Prairie, MN) (Figure 3, A). Particle image velocimetry (PIV) experiments (Figure 3, B) were performed to validate the 3D printed calcified aortic root model and compare with in-vivo ultrasound Doppler jet velocity for the patient. Detailed methodology of the PIV experiments may be found in literature 1. Comparison of the temporal velocity profile corresponding to a point located at the exit of the systolic jet of the valve (Figure 3, C) with Doppler data is shown in (Figure 3, D and E). As can be seen, the result shows good agreement between the in-vivo and in-vitro data. The maximum velocity in the PIV data was found to be 2.10 m/s which compares well with 2.24 m/s obtained from the ultrasound. Expansion tool with increasing diameter, which mimics balloon expansion (Figure 4, F).